Lead-Zinc Milling Process Wenglo

(PDF) Developments in Milling Practice at the Lead/Zinc

1997年1月1日Developments in Milling Practice at the Lead/Zinc Concentrator of Mount Isa Mines Limited from 1990

Rosh Pinah Mine Expansion Project, Namibia Mining

Project Location and GeologyMineralisation and ReservesMining MethodsMineral ProcessingInfrastructure FacilitiesContractors Involved

The existing processing plant contains a conventional three-stage crushing and ball milling circuit followed by sequential flotation process to produce lead and zinc concentrates. It currently operates at a throughput of between 0.68Mtpa and 0.71Mtpa to produce 50ktpa-60ktpa of zinc flotation concentrate and 4.5ktpa-7.5ktpa of lead flotation concen...

Developments in Milling Practice at the Lead/Zinc

AusIMM Sixth Mill Operators Conference, 6-8 October 1997 Madang, Papua New Guinea. ABSTRACT The Lead/Zinc Concentrator of Mount Isa Mines Limited processes complex

Overview of Zinc Production in Imperial Smelting Process

2017年10月5日Abstract and Figures The shaft furnace for simultaneous production of zinc and lead (ISF) which currently works in Miasteczko Slaskie in Poland, is the only one

Silver Lead Zinc Ore Processing Method using Flotation

2016年4月20日The recovery of silver minerals occurring in a lead-zinc sulfide ore is efficiently accomplished using the above flowsheet. The process consists of selective

How to Process Low-Grade Lead Zinc Ore by Flotation

2016年4月27日Lead and Zinc Pb-Zn Separation Process Circuit Primary Washing and Crushing A Drag or Conveyor is used to bring the dump material to a Revolving Trommel

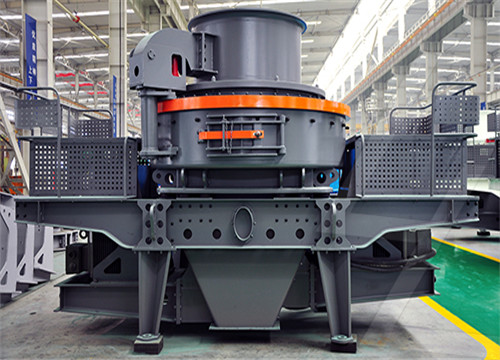

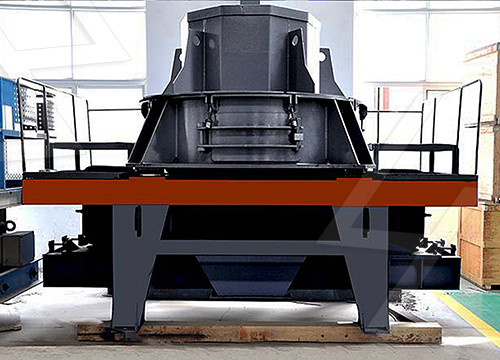

Lead-zinc ore crushing and grinding process mpl Ultrafine

2022年6月10日The processing and production process of lead-zinc ore mainly includes three processes: crushing, grinding and beneficiation. In the crushing process, the three

Tri-State Lead and Zinc District The Encyclopedia of

Lead and zinc mining was the Tri-State District's principal economic activity for more than eighty years. Production commenced in Missouri circa 1850. Although some surface

(PDF) Lead and Zinc Smelting Process at Kamioka, Japan

Lead and Zinc Smelting Process at Kamioka, Japan Journal of the Mining and Metallurgical Institute of Japan doi 10.2473/shigentosozai1953.84.963_816. Full Text Open PDF

Characterization of lead–zinc mill tailings, fly ash and their

2019年7月10日Disposal of mill tailings is a major concern for many countries as it pollutes the environment including water, air and soil (Yilmaz 2011; Jamieson et al. 2015; Lindsay et al. 2015).The large voids or stopes created after extraction of the ore from underground mines may serve as a suitable site for bulk disposal of the mill tailings, as the surface

(PDF) Developments in Milling Practice at the

1997年1月1日The Lead/Zinc Concentrator of Mount Isa Mines Limited processes complex fine grained ore from the Isa and Hilton silver-lead-zinc orebodies, producing lead concentrate, zinc concentrate and...

Developments in Milling Practice at the Lead/Zinc

AusIMM Sixth Mill Operators Conference, 6-8 October 1997 Madang, Papua New Guinea. ABSTRACT The Lead/Zinc Concentrator of Mount Isa Mines Limited processes complex fine grained ore from the Isa and Hilton silver-lead-zinc orebodies, producing lead concentrate, zinc concentrate and (until 1996) a low grade middlings (LGM or bulk)

Recovery of Lead from Zinc Plant Residue by Alkaline Leaching Process

2020年1月25日The primary zinc is produced from its sulfide ores such as sphalerite,which accounts for more than 80% of the metal obtained globally using the conventional hydrometallurgical process combining the roasting,leaching,purification, and electrowinning steps [1, 2].In the hydrometallurgical processing of zinc,the sulfide ore is

Impacts of lead/zinc mining and smelting on the environment

A large amount of lead, zinc, and related elements, such as cadmium, have been released into the environment due to mineral processing activities and have impacted water resources, soils, vegetables, and crops. In some areas, this pollution is hazardous to human health. This article reviews studies published in the past 10 years (2000-2009), on

Lead-zinc ore crushing and grinding process mpl Ultrafine

2022年6月10日The processing and production process of lead-zinc ore mainly includes three processes: crushing, grinding and beneficiation. In the crushing process, the three-stage closed-circuit crushing is a more modern method suitable for the crushing of high-hardness lead-zinc ore, which can complete the work of ore crushing and partial

Workshop report on milling machine and process. DEPARTMENT

2022年3月15日Milling is the most common form of machining, a material removal process, which can create a variety of features on a pa rt by cutting away the un wanted material. The milling process requires

Tri-State Mining District: Chat Mining Waste US EPA

Mining and milling of ore produced more than 500 million tons of wastes mine wastes contaminated with lead, zinc, cadmium, and other metals. product or as part of an industrial process (e.g., glass, glass recycling) where

Evaluation of Toxicity, Bioavailability and Speciation of

mitting process should probably take into consideration site-specific environmental conditions when evaluating 38 Evaluation of toxicity, bioavailability and speciation of lead, zinc and cadmium in mine/mill wastewaters CSBErten-Unal 22/11/02 10:56 am Page 38. with reagent grade nitric acid and taken for metal analysis.

Chat (mining) Wikipedia

Chat is fragments of siliceous rock, limestone, and dolomite waste rejected in the lead-zinc milling operations that accompanied lead-zinc mining in the first half of the 20th century. Historic lead and zinc mining in the

Tri-State Lead and Zinc District The Encyclopedia of

From 1908 through 1930 area mines turned out a total of more than $222 million in zinc and $88 million in lead, including more than 50 percent of the zinc and 45 percent of the lead needed in World War I. After 1915 more

A Mechanochemical Zinc-Mediated Barbier-Type Allylation

ABSTRACT: A Ball -milling enabled zinc mediated Barbier type allylation reaction is reported. Notably runnning the reaction in this manner renders it effective irrespective of the initial morphology of the zinc metal. The process is operationally simple, does not require inert atmospheres or dry solvents and is reported on a range of

Ball Mill an overview ScienceDirect Topics

The milling time increases with a decrease in the specific energy of the mill. Thus, a process that takes only a few minutes in a planetary mill can take hours in attritors and several days in commercial tumbling ball mills. Commercial batch NETZSCH attritors (Fig. 3.12) used industrially today are available in sizes from 115 to 720 L (Table 3.3).

An exploratory investigation of polar organic compounds in

Surface water samples were collected in 2006 from a lead mine-mill complex in Missouri to investigate possible organic compounds coming from the milling process. Water samples contained relatively high concentrations of dissolved organic carbon (DOC; greater than 20 mg/l) for surface waters but were colorless, implying a lack of naturally occurring aquatic

Characterization of lead–zinc mill tailings, fly ash and their

2019年7月10日Disposal of mill tailings is a major concern for many countries as it pollutes the environment including water, air and soil (Yilmaz 2011; Jamieson et al. 2015; Lindsay et al. 2015).The large voids or stopes created after extraction of the ore from underground mines may serve as a suitable site for bulk disposal of the mill tailings, as the surface

Developments in Milling Practice at the Lead/Zinc

AusIMM Sixth Mill Operators Conference, 6-8 October 1997 Madang, Papua New Guinea. ABSTRACT The Lead/Zinc Concentrator of Mount Isa Mines Limited processes complex fine grained ore from the Isa and Hilton silver-lead-zinc orebodies, producing lead concentrate, zinc concentrate and (until 1996) a low grade middlings (LGM or bulk)

Recovery of Lead from Zinc Plant Residue by Alkaline Leaching Process

2020年1月25日The primary zinc is produced from its sulfide ores such as sphalerite,which accounts for more than 80% of the metal obtained globally using the conventional hydrometallurgical process combining the roasting,leaching,purification, and electrowinning steps [1, 2].In the hydrometallurgical processing of zinc,the sulfide ore is

Impacts of lead/zinc mining and smelting on the environment

A large amount of lead, zinc, and related elements, such as cadmium, have been released into the environment due to mineral processing activities and have impacted water resources, soils, vegetables, and crops. In some areas, this pollution is hazardous to human health. This article reviews studies published in the past 10 years (2000-2009), on

Tri-State Lead and Zinc District The Encyclopedia of

From 1908 through 1930 area mines turned out a total of more than $222 million in zinc and $88 million in lead, including more than 50 percent of the zinc and 45 percent of the lead needed in World War I. After 1915 more

Lead-zinc ore crushing and grinding process mpl Ultrafine

2022年6月10日The processing and production process of lead-zinc ore mainly includes three processes: crushing, grinding and beneficiation. In the crushing process, the three-stage closed-circuit crushing is a more modern method suitable for the crushing of high-hardness lead-zinc ore, which can complete the work of ore crushing and partial

Tri-State Mining District: Chat Mining Waste US EPA

Mining and milling of ore produced more than 500 million tons of wastes mine wastes contaminated with lead, zinc, cadmium, and other metals. product or as part of an industrial process (e.g., glass, glass recycling) where

Evaluation of Toxicity, Bioavailability and Speciation of

mitting process should probably take into consideration site-specific environmental conditions when evaluating 38 Evaluation of toxicity, bioavailability and speciation of lead, zinc and cadmium in mine/mill wastewaters CSBErten-Unal 22/11/02 10:56 am Page 38. with reagent grade nitric acid and taken for metal analysis.

Chat (mining) Wikipedia

Historic lead and zinc mining in the Midwestern United States was centered in two major areas: the tri-state area covering more than 2,500 square miles (6,500 km 2) in southwestern Missouri, southeastern Kansas, and

(PDF) An Exploratory Investigation of Polar Organic

2011年5月1日Surface water samples were collected in 2006 from a lead mine–mill complex in Missouri to investigate possible organic compounds coming from the milling process.

A Mechanochemical Zinc-Mediated Barbier-Type Allylation

A range of zinc sources was explored for the reaction of 4-fluorobenzaldehyde with allyl bromide and it was established that as well as zinc flake, zinc foil, zinc mesh, zinc wire and zinc shot are all effective under milling condi- tions, without any pre-treatment.

Bunker Hill Mine and Smelting Complex Wikipedia

By 1948, the mill had a 3000 tons per day capacity, the smelter produced almost 10,000 tons of lead per month, the zinc plant had a capacity of over 4000 tons of zinc per month, and the cadmium plant was capable of

Workshop report on milling machine and process. DEPARTMENT

2022年3月15日Milling is the most common form of machining, a material removal process, which can create a variety of features on a pa rt by cutting away the un wanted material. The milling process requires

Ball Mill an overview ScienceDirect Topics

The milling time increases with a decrease in the specific energy of the mill. Thus, a process that takes only a few minutes in a planetary mill can take hours in attritors and several days in commercial tumbling ball mills. Commercial batch NETZSCH attritors (Fig. 3.12) used industrially today are available in sizes from 115 to 720 L (Table 3.3).