De Watering Screen

Dewatering Screens McLanahan

Dewatering Screens can be used to dewater -4 mesh (5 mm) particles of sand, coal, iron ore, salt, etc., as well as for limited efficiency fine sizing, washing and rinsing, desliming

Dewatering Screens Multotec

根据热度为您推荐•反馈

Dewatering Screen Washing Equipment Superior

根据热度为您推荐•反馈

Dewatering Screens Astec

Our dewatering screens can produce a finished fine material product with a moisture content as low as 8 percent. These single-deck screens dewater fine aggregates prior to stockpiling. By utilizing a dewatering screen,

Dewatering Screens Wet Screens Derrick Machine

Dewatering screens, or wet screens, provide a wide range of sizing and classification tasks. Wet screens efficiently screen out fines and classify oversize particles. All Derrick

De-Watering Screens by Hewitt Robins International

Hewitt Robins can supply Dewatering Screens ranging from capacities as little as 10tph up to capacities as high as 400tph. Hewitt Robins have experience in de-watering materials ranging from fine sands, crushed

Dewatering Screens Retaining Fines Washing

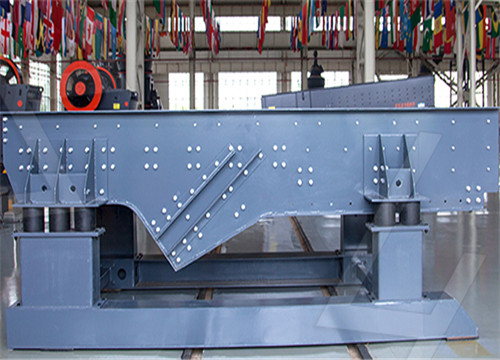

Dewatering Screen Whilst primarily applied for dewatering with retained fines, dewatering screens are capable of being used in a wide range of applications. The screen incorporates a 45° sloping back deck

Dewatering Screen 911Metallurgist

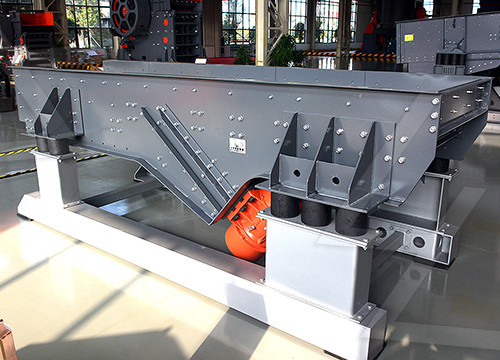

Horizontal Dewatering Screens The horizontal screens used for dewatering are actually not exactly set at 0°. It has proven to be very beneficial to set them up at a negative incline of about 3°. As for the applications

Dewatering Screens Eagle Iron Works

The Eagle Dewatering Screen is installed horizontally, as opposed to on an incline. Because this Dewatering Screen is specifically designed to be fed by a Fine Material Washer, the majority of water content has already

Dewatering Screens Support McLanahan

Dewatering Screen media typically lasts longer than sizing screen media. Check the media surfaces once a week for cracks and oversized holes/slots. Remove and replace the media as necessary, following the manual's

Dewatering Screens Multotec

Dewatering Screens Multotec helps you reduce water content of your product with a complete range of dewatering screens. We manufacture a variety of wedge wire and polyurethane dewatering screen panels for

UltraDRY Modular Dewatering Screens McLanahan

McLanahan’s UltraDRY Dewatering Screen is a field-proven design based on decades of process knowledge and experience. McLanahan customers have achieved as low as 7% moisture content when adding a

Dewatering Screens McLanahan

McLanahan Dewatering Screens have been known to achieve as low as 7% moisture content in sand products. A drier product means less stockpiling time for quicker sale, less mess under conveyors and less water lost to waste. All this adds up to a more profitable site for your operation.

Dewatering Screens Wet Screens Derrick Machine

Dewatering Screens. Dewatering screens, or wet screens, provide a wide range of sizing and classification tasks. Wet screens efficiently screen out fines and classify oversize particles. All Derrick machine dewatering units have a proven throughput of up to 300 tons per hour and are designed to maximize solids recovery and minimize wastewater.

De-Watering Screens by Hewitt Robins International

Hewitt Robins can supply Dewatering Screens ranging from capacities as little as 10tph up to capacities as high as 400tph. Hewitt Robins have experience in de-watering materials ranging from fine sands, crushed

How a dewatering screen works. YouTube

2017年6月23日11K views 5 years ago GTEK high frequency dewatering screens are highly versatile and well suited for heavy duty applications in sand and aggregates, mining and mineral

Dewatering Screens Retaining Fines Washing

Dewatering Screen Whilst primarily applied for dewatering with retained fines, dewatering screens are capable of being used in a wide range of applications. The screen incorporates a 45° sloping back deck

8 Reasons To Use A Dewatering Screen In Your

A Dewatering Screen is specifically set up to blind the screen media in order to retain material to the overs and allow the water to report to the unders. With this mind, it is still a screen, and the media can be adjusted

Dewatering Screens Classification and Flotation

Dewatering screens are well proven in all types of construction and industrial sands. CFS Dewatering screens will handle more tonnage and outperform any dewatering screen on the market. High speed motors

Dewatering Screens Vibramech

Dewatering Screens Vibramech dewatering screens are specifically designed for mineral dewatering processes in order to generate a conveyable discharge cake of material. This is achieved by combining

The demystification of dewatering screens Quarry

2020年3月19日Studies have shown the key to dewatering screen performance is droplet formation at the underside of the screen media. {{image3-a:r-w:250}}Essentially, the upward acceleration and amplitude

Dewatering Screen Don Valley Engineering

Dewatering Screens. Our range VS type dewatering screens has been designed specifically for the drainage of wet, often fine minerals, from the carrying fluid. To do this they employ a number of features including a

Dewatering Screens SandAggregate Screening Equipment

Patented dewatering screening technology offering superior dewatering, lifetime performance and power consumption reduction. PATENTED INFINITY™ DEWATERING SCREENING TECHNOLOGY THE INFINITY™ STANDARD The Infinity™ screens dewatering line are galvanised as standard for ultimate screen life longevity.

Dewatering Screen AZFAB AZ Fines Aggregate

The AZFAB dewatering screen can produce products with average moisture content of only 12 to 14% depending on particle size and tonnage, with some plants delivering material with rates as low as 7%. The AZFAB

UltraDRY Modular Dewatering Screens McLanahan

McLanahan’s UltraDRY Dewatering Screen is a field-proven design based on decades of process knowledge and experience. McLanahan customers have achieved as low as 7% moisture content when adding a

The demystification of dewatering screens Quarry

2020年3月19日Dewatering screens were first introduced to the mining industry nearly 40 years ago as a more efficient means of dewatering minus 6.35mm solids contained in slurries. In most operations they replaced

Dewatering Screens McLanahan

McLanahan Dewatering Screens have been known to achieve as low as 7% moisture content in sand products. A drier product means less stockpiling time for quicker sale, less mess under conveyors and less water lost to waste. All this adds up to a more profitable site for your operation.

Dewatering Screens Wet Screens Derrick Machine

Dewatering Screens. Dewatering screens, or wet screens, provide a wide range of sizing and classification tasks. Wet screens efficiently screen out fines and classify oversize particles. All Derrick machine dewatering units have a proven throughput of up to 300 tons per hour and are designed to maximize solids recovery and minimize wastewater.

De-Watering Screens by Hewitt Robins International

Hewitt Robins can supply Dewatering Screens ranging from capacities as little as 10tph up to capacities as high as 400tph. Hewitt Robins have experience in de-watering materials ranging from fine sands, crushed

Sidehill Screens Parabolic Dewatering JWC Environmental

Specifications. SHS Static Screen widths range from 12 to 120 inches (300 3050 mm) SHS flows up to 2000 gpm ( 454 m 3 /hr) SHS Dewatering Screen decks are offered in 38, 42 or 54-inch lengths. SHP hydraulic capacity: 300-600 gpm (68 to 136 m 3 /hr)per single unit, depending on the application.

8 Reasons To Use A Dewatering Screen In Your

A Dewatering Screen is specifically set up to blind the screen media in order to retain material to the overs and allow the water to report to the unders. With this mind, it is still a screen, and the media can be adjusted

Dewatering Screens Classification and Flotation

Dewatering screens are well proven in all types of construction and industrial sands. CFS Dewatering screens will handle more tonnage and outperform any dewatering screen on the market. Features High speed

Dewatering Screen Don Valley Engineering

Dewatering Screens. Our range VS type dewatering screens has been designed specifically for the drainage of wet, often fine minerals, from the carrying fluid. To do this they employ a number of features including a

How McLanahan's UltraDRY Modular Dewatering Screen Works

2020年3月23日How McLanahan's UltraDRY Modular Dewatering Screen Works McLanahan Corporation 1.57K subscribers 17K views 2 years ago McLanahan's UltraDRY is a compact, modular, skid

Dewatering Screen AZFAB AZ Fines Aggregate

The AZFAB dewatering screen can produce products with average moisture content of only 12 to 14% depending on particle size and tonnage, with some plants delivering material with rates as low as 7%. The AZFAB

Dewatering Screens SandAggregate Screening Equipment

Patented dewatering screening technology offering superior dewatering, lifetime performance and power consumption reduction. PATENTED INFINITY™ DEWATERING SCREENING TECHNOLOGY THE INFINITY™ STANDARD The Infinity™ screens dewatering line are galvanised as standard for ultimate screen life longevity.

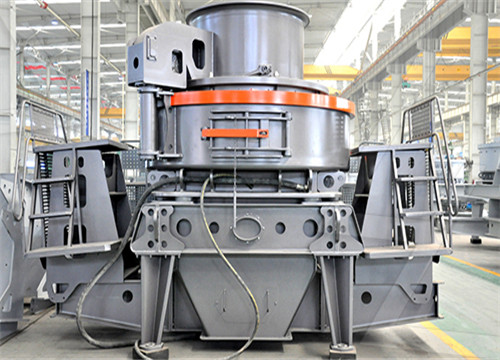

Dewatering Screen Conn-Weld

DESCRIPTION. Conn-Weld’s High-Frequency Dewatering Screens are designed to handle one of the toughest challenges in screening dewatering. The feed end is declined at 45 degrees, while the main deck is inclined at 5 degrees, creating a thick bed depth that traps fine particles and allows the water to drain more effectively.

Dewatering Screens Kwatani

Kwatani dewatering screens are custom designed to meet the specific process requirements and ensure superior water removal without losing excess fines. Kwatani’s mechanically robust designs handle the harshest mining applications. In-house finite element analysis (FEA) on each custom design for optimum performance.