Raymond Roller Mill Oil Lubricant Viscosity

How to Maintain My Raymond Mill to Improve the

2019年9月9日4) the roller grinding ring is out of circle; 5) the anchor bolt is loose. Solutions: 1) adjust the feed quantity; 2) replace the worn-out blade with new one; 3) control the feed particle size; 4) replace the grinding

Rolling oil Mobil™

High-performance, synthetic low staining bearinggear oil for rolling mills. Used when bearing lubricating oils contaminate rolling oil. Wyrol™ MS 220. Synthetic, low staining

进一步探索

Fact sheet: Somentor fluids for aluminum rolling oil EMEAFCNA Rolling oil composition for cold-rolled sh根据热度为您推荐•反馈

What You Need to Know When Selecting Gear Oils

2019年6月21日Selecting lubricants for industrial gearing is similar in most applications. There is no specific property or value to create a good

Effect of lubricant viscosity grade on mechanical vibration

2007年8月1日Changes in lubrication regime of roller bearings due to change in oil viscosity grade could be detected by vibration monitoring. In the tests with ISO 32 and

Raymond Mill History, Working PrincipleApplications

1.First Generation of Raymond Mill. In 1906, C.V. Grueber founded a machinery factory in the southern suburbs of Berlin. Using his patents obtained in the United States, he

Cold and Foil Rolling Lubricants: Monitoring Innoval

2019年6月7日The base oil dissolves the additives and provides sufficient viscosity to maintain stable mill rolling conditions. The additives deliver load bearing capacity and

Understanding Oil ViscosityBearing Lubrication

2019年6月13日Oil in process pumps is typically an ISO grade 32, 46, 68 or 100. These numbers relate to the kinematic viscosity in centistokes. The oil can be hydrocarbon oil, although synthetic oils are used for specific

Improving Rolling Mill Lubricant Oil with Vacuum Dehydration

2021年4月22日These rolling mill lubricant oils may be known as Morgoil as they are commonly used on Morgan rolling mill systems. Fluid Demulsibility and Decanting High

Chain Lubrication Best Practices for Drives and Conveyors

Roller chains are produced in 0.25 through 3.0-inch pitch and are used for a wide variety of drives in the slow to high-speed range. Silent chains are produced in 0.375 through 2.0-inch pitch, run smoother than roller

Effect of lubricant viscosity grade on mechanical vibration of roller

2007年8月1日Changes in lubrication regime of roller bearings due to change in oil viscosity grade could be detected by vibration monitoring. In the tests with ISO 32 and ISO 68 viscosity grades, lubrication regime was of full film type. With the ISO 10 grade, lubrication regime was supposed to be very near to that of mixed type. •

What You Need to Know When Selecting Gear Oils Machinery Lubrication

Selecting lubricants for industrial gearing is similar in most applications. There is no specific property or value to create a good specification. To identify the best choice for a given application, the right viscosity, base oil and type of lubricant must be selected and the appropriate performance properties evaluated. For more information

Extremely high viscosity grease with solid lubricants SKF

Extremely high viscosity grease with solid lubricants. SKF LGEV 2 is a mineral oil based grease, using a lithium-calcium soap. High pressure roller mills; Crushers; Base oil viscosity: 40 °C, mm²/s : 1 020: 100 °C, mm²/s: 47.5: Penetration DIN ISO 2137 : 60 strokes, 10 –1 mm:

ISO Viscosity Grades Machinery Lubrication

So, viscosity is a measure of the fluid’s resistance to flow. Water has a low viscosity of 1 cSt and honey has a very high viscosity, lets say 1,000 cSt. If a machine is heavily loaded then the machine designer will use a lubricant that resists being pushed around, which would be heavy like honey.

Understanding Oil ViscosityBearing Lubrication

2019年6月13日Use of the correct viscosity lubricant for the speed, temperature and loads ensures the development of a full oil film between rotating parts. The optimum fluid film is sufficiently thick to allow the rolling elements to function without metal-to-metal contact with minimum friction.

Raymond Mill History, Working PrincipleApplications

1.First Generation of Raymond Mill. In 1906, C.V. Grueber founded a machinery factory in the southern suburbs of Berlin. Using his patents obtained in the United States, he produced the first Maxecon mill and used it as the coal grinding equipment for the MOABIT power station. The grinding power can reach 5TPH.

Low-viscosity Gear Oil Technology to Improve Wear at Tapered Roller

2016年10月17日One effective way is to decrease the viscosity of lubricants as it results in less churning loss. However, this option creates a higher potential for thin oil films, which could damage the mechan Low-viscosity Gear Oil Technology to Improve Wear at Tapered Roller Bearings in Differential Gear Unit 2016-01-2204. This low-viscosity

Why is viscosity important for bearing lubrication? Motion

2019年1月10日One of the most important characteristics of a lubricant is its viscosity (or, in the case of grease lubricant, the viscosity of the base oil). But viscosity is analogous to friction in fluids. So why do you need friction (in lubrication) in order to reduce friction (in bearings)?

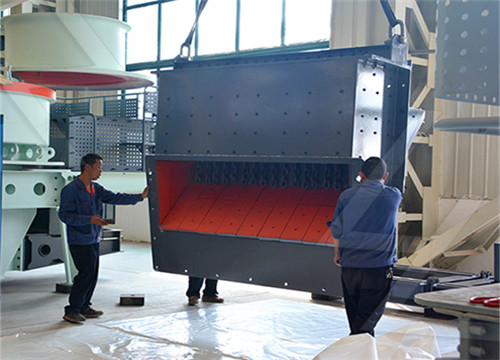

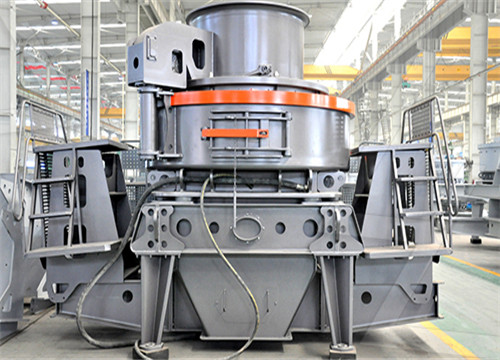

Felipe H. Giacomazzi on LinkedIn: #grinding #raymond #rollermill

Raymond Roller Mill Final test before shipping! #grinding #raymond #rollermill #wemakeprocesswork #schenckprocess

Improving Rolling Mill Lubricant Oil with Vacuum Dehydration

2012年8月7日Benefits of Vacuum Dehydration for Rolling Mill Lubricant Oil. Steel mills typically use lubricants with high demulsibility for rolling mill back-up roller bearings and chocks since relatively high levels of water contaminate the oil from quenching and descaling processes. These rolling mill lubricant oils may be known as Morgoil as they

The Most Common Causes of Bearing Failure and the Importance of Bearing

2020年3月17日In order to form an adequate lubricant film between the rolling contact surfaces, the lubricant must retain a certain minimum viscosity while at operating temperature. The bearing life may be extended by increasing the operating viscosity, .

en/lubrication raymond mill bowl mill.md at main sbmboy/en

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

Viscosity of lubricants ScienceDirect

2001年1月1日Viscosity is a measure of the internal friction of a fluid. It is the most important physical property of a fluid in the context of lubrication. The viscosity of a lubricant varies with temperature and pressure and, in some cases, with the rate at which it is sheared. Dynamic viscosity is explained as it is the lubricant property involved in

Rolling Bearing Lubricants SpringerLink

The primary property is the lubricant viscosity. The lubricant viscosity varies exponentially with temperature for both grease and oil, thus an appropriate viscosity-temperature index is required to cover the operating temperature range. Lubricant viscosity also changes exponentially with pressure.

Effect of lubricant viscosity grade on mechanical vibration of roller

2007年8月1日According to the performed analyses, it can be concluded that changes in oil viscosity, caused by either the use of different ISO viscosity grades or temperature variation, only affect the vibration of the rolling bearing in

What You Need to Know When Selecting Gear Oils Machinery Lubrication

Selecting lubricants for industrial gearing is similar in most applications. There is no specific property or value to create a good specification. To identify the best choice for a given application, the right viscosity, base oil and type of lubricant must be selected and the appropriate performance properties evaluated. For more information

ISO Viscosity Grades Machinery Lubrication

So, viscosity is a measure of the fluid’s resistance to flow. Water has a low viscosity of 1 cSt and honey has a very high viscosity, lets say 1,000 cSt. If a machine is heavily loaded then the machine designer will use a lubricant that resists being pushed around, which would be heavy like honey.

Extremely high viscosity grease with solid lubricants SKF

It has a high content of molybdenum disulphide and graphite, in conjunction with an extremely high viscosity oil. This provides outstanding protection under the harshest conditions involving high loads, slow rotations and severe vibrations. Featuresbenefits

Raymond Mill History, Working PrincipleApplications

The Raymond Mill is a grinding machine, suitable for the preparation of various kinds of mineral powder and coal powder preparation. Materials: Barite, calcite, potash feldspar, talc, marble, limestone, dolomite, fluorspar, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, etc.

Low-viscosity Gear Oil Technology to Improve Wear at Tapered Roller

2016年10月17日One effective way is to decrease the viscosity of lubricants as it results in less churning loss. However, this option creates a higher potential for thin oil films, which could damage the mechan Low-viscosity Gear Oil Technology to Improve Wear at Tapered Roller Bearings in Differential Gear Unit 2016-01-2204. This low-viscosity

Improving Rolling Mill Lubricant Oil with Vacuum Dehydration

2012年8月7日These rolling mill lubricant oils may be known as Morgoil as they are commonly used on Morgan rolling mill systems. Fluid Demulsibility and Decanting High-quality rolling mill oils are similar to turbine oil in that they are made from high-quality base stocks and contain little to no additives.

Why is viscosity important for bearing lubrication? Motion

2019年1月10日One of the most important characteristics of a lubricant is its viscosity (or, in the case of grease lubricant, the viscosity of the base oil). But viscosity is analogous to friction in fluids. So why do you need friction (in lubrication) in order to reduce friction (in bearings)?

Felipe H. Giacomazzi on LinkedIn: #grinding #raymond #rollermill

Raymond Roller Mill Final test before shipping! #grinding #raymond #rollermill #wemakeprocesswork #schenckprocess

Viscosity of lubricants ScienceDirect

2001年1月1日Viscosity is a measure of the internal friction of a fluid. It is the most important physical property of a fluid in the context of lubrication. The viscosity of a lubricant varies with temperature and pressure and, in some cases, with the rate at which it is sheared. Dynamic viscosity is explained as it is the lubricant property involved in

08-Lubrication of Vertical Roller Mills-Fuchs Lubritec

18 Lubrication of MPS-MPS-Mills / Roller Bearings. From the lubricant point of view the roller lubrication is the most critical part on a vertical mill. Therefore a regular oil monitoring is essential for a long lifetime of the bearings. The whole system must be traced for any leakages. If oil leaks dust can penetrate into the system

Equipment Maintenance Guide Phillips 66 Lubricants

For example, a 5W viscosity grade requires the lubricant to flow properly at lower temperatures than a 15W viscosity grade, so it is expected to be used at lower starting temperatures. In tropical weather, most OEMs still recommend multi-grade products, such as SAE 15W-40, because the lubricant flows faster through the engine than a pure SAE

en/lubrication raymond mill bowl mill.md at main sbmboy/en

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

Rolling Bearing Lubricants SpringerLink

The primary property is the lubricant viscosity. The lubricant viscosity varies exponentially with temperature for both grease and oil, thus an appropriate viscosity-temperature index is required to cover the operating temperature range. Lubricant viscosity also changes exponentially with pressure.