Crusher Instruction Manual Raw Milling Cement Project Cost

Cement Crusher Cement Crusher For Sale Jaw Crusher, Cone

Before sending it into the raw mill, the cement raw material should be crushed into small

Preparation Of Cement Raw Material Cement Mill, Cement Crusher

The raw material production of cement plant can be classified into four steps: crushing,

进一步探索

Cement Manufacturing Process Phases Flow Chart CeRAW MATERIALS IN CEMENT PRODUCTION根据热度为您推荐•反馈

Analysis of Raw Mill Machines Maintenance in Cement

2020年5月30日The raw mill machine functions as a main material grinder in the initial milling process such as limestone, silica stone, clay, and

instruction manual of cement production line process Mobile

The following, we will give a detailed information about instruction manual of cement

Cement Plant Practical site view Crusher Raw mill Kiln

Cement Plant Practical site view Crusher Raw mill Kiln Preheater Cement mill#cementplant #LSCrusher #Rawmill #Kiln #Preheater #Rotarykiln

Cement Crusher Cement Crusher For Sale Jaw Crusher, Cone Crusher

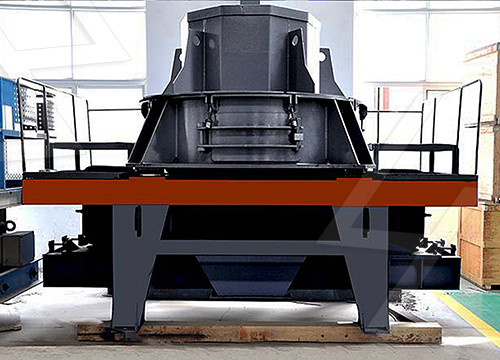

Cement crusher refers to the stone crusher in the cement industry, as a part of the cement plant, it plays a vital role in the cement production line. Before sending it into the raw mill, the cement raw material should be crushed into small sizes by

Cone Crusher For Sale Cement Crusher Cone

Cone crusher for sale. Production Capacity: 12-1,814m³/h. Feeding Size: ≤350mm. Application: cobble, granite, basalt, iron ore, limestone, quartz stone, diabase, gold ore and copper ore, etc. !. Cone cement

Homogenization of Cement Raw Meal AGICO Cement Plant

The raw meal preparation process of the cement industry includes four links: mining, pre-homogenization, grinding, and homogenization, which form the homogenization chain of raw meal preparation. Raw meal homogenization is the most important process link of the four, accounting for 40% of the homogenization task.

Raw Material Crushing Jaw Crusher|Hammer

Crushers used for Cement Production-Raw Material Crushing: Jaw Crusher, Hammer Crusher,Impact Crusher, Vertical Crusher. How to Reduce Production Cost of Cement Vertical Mill. Project; News;

JK Cement Works, GOTAN

Cement Clinker 1 Crusher Main Lime Stone Crusher: 2 Raw Mill For new line TPA clinker production the requirement of raw Mix is about TPA. We require approx. Estimated Cost proposed projects Cost: 1250 crore (Rajeev Sharma) Unit Head

Process Flow Sheet For 100 Tons Cement Mill Crusher Mills

Bursa Cement Factory Co., Inc Production Flow Sheet. Bursa Cement Factory Co., Inc Production Flow Sheet RAW MATERIAL PREPARING RDF PREPARING RDF STOCK 1.000 Ton RAW MILL-1 200 t/h RAW MILL-2 52 t/h RAW MILL-3 100 t/h.

Cement Plant Project List Completed in History

Project Date:2011-06. Raw material: Clay, Limestone. Main equipment configuration: 2 Ball mill. Project Introduction: Shandong Tiancheng choose AGICO for second time for 1500t/d cement production line EPC

Vertical Roller Mill for Cement Raw Material

The vertical mill’s drying capacity is strong, and the waste heat of the kiln can be used to dry the raw materials with a moisture content of 8% or higher. The air ring area, the air ring angle, and the dam ring’s height can

Plysius Cement Vartical Mill Crusher Mills

polysius vertical mill maintenance manuals Grinding Mill polysius vertical mill maintenance manuals. Posted at: October 27, 2012 [ 4.9 2798 Ratings] Loesche vertical roller mills for raw and cement grinding.

Mark Joseph Samson Project Management Head

Mechanical engineer with more than 10 years of solid experience in construction of Industrial plant (Cement Manufacturing and Pollution

5 Cost-saving Tips for Portland Cement Manufacturers

In a cement production line of 3 000 t / a, the cement kiln can treat nearly 10 × 104 tons of waste, basically realizing the cost-saving and waste material harmlessness. Cement Kiln Tip 5: Secondary Use the Waste Heat The secondary use of the resource is also a

en/fls manuals of hammer mill pdf.md at main sbmboy/en

Impact Fls Ev 200300 Crusher; Impact Crusher Untuk 10 Ton Hour Coal Russian.impact crusher for cemet plant grinding mill cement plant impact crusher.hammers for ev200 crusher devalklier.impact fls ev 200300 crusher.EV hammer impact crusher 4 1 Hammer rotor 2 Inlet roller 3 Hammers fls impact hammer crusher ev200*300 Get free

What are the cement mill pre-crushing equipment

2023年2月13日What are the cement mill pre-crushing equipment ? mpl-crusher Published Feb 13, 2023 + Follow In the cement manufacturing process, the raw materials need to be pre-crushed before being...

Why is a crusher section used in the cement industry?

2023年3月1日A crusher section is used in the cement industry to reduce the size of raw materials such as limestone, clay, and other materials. The crushed material is then used as an input into the...

Homogenization of Cement Raw Meal AGICO Cement Plant

The raw meal preparation process of the cement industry includes four links: mining, pre-homogenization, grinding, and homogenization, which form the homogenization chain of raw meal preparation. Raw meal homogenization is the most important process link of the four, accounting for 40% of the homogenization task.

Raw Material Crushing Jaw Crusher|Hammer

Crushers used for Cement Production-Raw Material Crushing: Jaw Crusher, Hammer Crusher,Impact Crusher, Vertical Crusher. How to Reduce Production Cost of Cement Vertical Mill. Project; News;

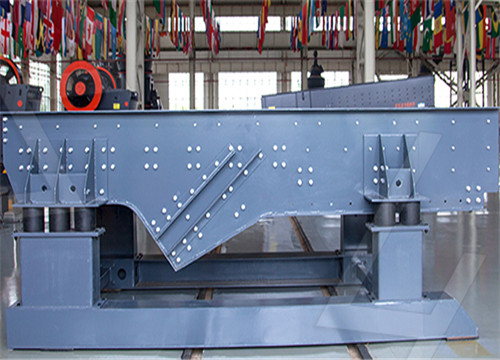

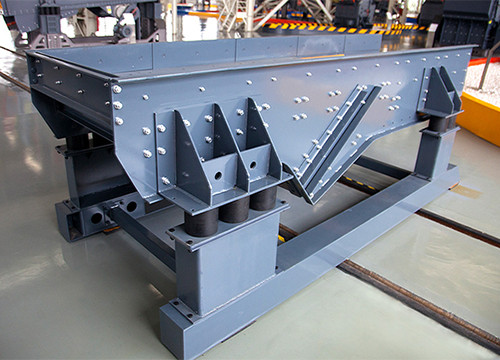

Raw Mill for sale, Raw Mill Process, Raw Mill Machine ZENITH Crusher

Raw Mill. Raw mill is mainly used in grinding raw materials and end products in cement plant. It is also suitable for various ores and other materials metallurgy, mine, chemical and construction. Besides, it has two forms of milling, one is an open form, and the other is a recycle close form equipped with powder concentrator.

JK Cement Works, GOTAN

Cement Clinker 1 Crusher Main Lime Stone Crusher: 2 Raw Mill For new line TPA clinker production the requirement of raw Mix is about TPA. We require approx. Estimated Cost proposed projects Cost: 1250 crore (Rajeev Sharma) Unit Head

Process Flow Sheet For 100 Tons Cement Mill Crusher Mills

Bursa Cement Factory Co., Inc Production Flow Sheet. Bursa Cement Factory Co., Inc Production Flow Sheet RAW MATERIAL PREPARING RDF PREPARING RDF STOCK 1.000 Ton RAW MILL-1 200 t/h RAW MILL-2 52 t/h RAW MILL-3 100 t/h.

Cement Plant Project List Completed in History

The project lasted from June 2010 to October 2010. Slag vertical roller mill works stably with the yield of 1600t/d, after the equipment update, power consumption of the production line reduced to 38 KWh/t, which reached

Ball Mill an overview ScienceDirect Topics

Quantum Nanostructures (QDs): An Overview. D. Sumanth Kumar, H.M. Mahesh, in Synthesis of Inorganic Nanomaterials, 2018 3.6.1.1 Ball Milling. A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized balls. The working principle is simple; impact and attrition size reduction take place as the ball

Cement Mill Portions Replacement Pdf Crusher Mills

Pe-250×400 Crusher Operational Cost; Powder Making Machine Video; Chp Ppt Buisness Plan Stone Crusher; CHANDERIA WRITE UP ON PROJECTS (2003 BIRLA CEMENT WORKS, CHANDERIA WRITE UP ON PROJECTS (2003 04) 1. l The 6.6 kV fix speed raw mill drives and cement mill drives despite this, it was time to replace the system.

Vertical Roller Mill for Cement Raw Material

The vertical mill’s drying capacity is strong, and the waste heat of the kiln can be used to dry the raw materials with a moisture content of 8% or higher. The air ring area, the air ring angle, and the dam ring’s height can

5 Cost-saving Tips for Portland Cement Manufacturers

In a cement production line of 3 000 t / a, the cement kiln can treat nearly 10 × 104 tons of waste, basically realizing the cost-saving and waste material harmlessness. Cement Kiln Tip 5: Secondary Use the Waste Heat The secondary use of the resource is also a

Mark Joseph Samson Project Management Head

Mechanical engineer with more than 10 years of solid experience in construction of Industrial plant (Cement Manufacturing and Pollution

BASIC CEMENT PLANT LAYOUT Process Cement Forum The Cement

2020年7月4日14 Cement Mill and Bag House . Clinker, along with additives, is ground in a cement mill. The output of a cement mill is the final product viz. Cement. In a cement mill, there is a cylindrical shell lying horizontal which contains metallic balls and as it rotates, the crushing action of the balls helps in grinding the clinker to a fine powder.

en/fls manuals of hammer mill pdf.md at main sbmboy/en

Impact Fls Ev 200300 Crusher; Impact Crusher Untuk 10 Ton Hour Coal Russian.impact crusher for cemet plant grinding mill cement plant impact crusher.hammers for ev200 crusher devalklier.impact fls ev 200300 crusher.EV hammer impact crusher 4 1 Hammer rotor 2 Inlet roller 3 Hammers fls impact hammer crusher ev200*300 Get free