Screening Plant Iron Ore

Advances in screening technology in the mining sector

Screening equipment is installed after the primary crusher, after the scrubber and after the tertiary comminution stage to separate the iron ore into a dry coarse fraction (8 40

The six main steps of iron ore processing Multotec

Screening. We recommend that you begin by screening the iron ore to separate fine

Ore, RockAggregate Screening (Complete Guide)

2016年6月20日Screening capacity can be described by the following formula with factors specified below: Qu = A x B x C x D x E x F x G x H

Iron ore pelletizing Metso Outotec

Our iron ore pelletizing systems combine the best features of both technologies to provide the most modern plant and to produce pellets at the lowest cost and highest quality. Pellet plants sized from 1.2MTPA to

Iron Ore Pellets Screening Solutions metal7

Iron Ore Pellets Screening Solutions The size distribution of iron ore pellets is among the most important quality parameters for the end users of those pellets, the steel mills. The

(PDF) ORE SEPARATION BY SCREENING ResearchGate

2017年3月3日ORE SEPARATION BY SCREENING March 2017 DOI: 10.13140/RG.2.2.14773.68325 Report number: 2 Affiliation: University of Mysore Authors: A. Balasubramanian University of Mysore Abstract and

Iron Ore Screening Plant- Fines Line YouTube

2021年11月1日Iron Ore Screening Plant- Fines Line Fe2O3Fe3O4 MiningProcessing 18.5K subscribers Subscribe 311 Share 24K views 1 year ago #ironore

mpl screening plants for iron ore mining in Odisha

mpl screening plants for iron ore mining in Odisha. May 08,2021. India is bestowed with large reserves of iron ore and it is the second largest producer of steel across the

Screening and crushing plant #iron_ore #steel_plant

2023年3月10日About Press Copyright Contact us Creators Advertise Developers Terms Privacy Press Copyright Contact us Creators Advertise Developers Terms Privacy

Developments in iron ore comminution and classification

2015年1月1日Iron ore crushing and screening Iron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel. About 98% of the mined iron ore is used to make steel either by the blast furnace—basic oxygen furnace (BF-BOF) route—or through the electric arc furnace (EAF) route.

Screening Plant an overview ScienceDirect Topics

A. Jankovic, in Iron Ore, 2015 8.2.4 Mobile crushing and screening plant applications for small- to medium-sized iron ore projects There is now a new generation of mobile crushing and screening plant systems, which have been developed based on the motivation of reducing truck haulage.

Iron Ore Screening Multotec

Iron ore screening equipment from Multotec is made from polyurethane or rubber screening media. Our screening equipment is ideal for high, medium or low grade profiles, reduce plant footprint by more than 33% and materials of construction ensure a long life at reduced cost with low maintenance requirements.

Iron ore pelletizing Metso Outotec

Our iron ore pelletizing systems combine the best features of both technologies to provide the most modern plant and to produce pellets at the lowest cost and highest quality. Pellet plants sized from 1.2MTPA to

The six main steps of iron ore processing Multotec

1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

(PDF) ORE SEPARATION BY SCREENING ResearchGate

2017年3月3日ORE SEPARATION BY SCREENING March 2017 DOI: 10.13140/RG.2.2.14773.68325 Report number: 2 Affiliation: University of Mysore Authors: A. Balasubramanian University of Mysore Abstract and

Screening 101 Mineral ProcessingMetallurgy

2016年6月10日Screening 101. Screening is the passing of material through definite and uniform apertures is the only true and accurate means of grading to a required particle size. Air separation and hydraulic

Iron Ore Processing,Crushing,Grinding Plant Machine

Based on the iron ore processing experience and necessary processing tests, Prominer can supply complete processing plant combined with various processing technologies, such as gravity separation, magnetic

mpl screening plants for iron ore mining in Odisha

mpl screening plants for iron ore mining in Odisha. May 08,2021. India is bestowed with large reserves of iron ore and it is the second largest producer of steel across the globe. India’s total iron ore production for the year CY19 was 231 million MTs which enabled 90 per cent (111 million MTs) of steel production.

Screening and crushing plant #iron_ore #steel_plant YouTube

2023年3月10日About Press Copyright Contact us Creators Advertise Developers Terms Privacy Press Copyright Contact us Creators Advertise Developers Terms Privacy

Iron ore processing plant CDE Asia

Processed Iron Ore increases campaign life. Fine particles and Alumina in the feed end up as accretions in the kiln walls. Lower Alumina in the feed means a considerable reduction in cleaning and maintenance of the

Sintering: A Step Between Mining Iron Ore and Steelmaking

2019年6月11日Seven open-pit iron ore mines (each with associated concentration and pelletizing plants), and three iron metallic plants—one direct-reduced iron (DRI) plant and two hot-briquetted iron (HBI) plants— operated during the year to supply steelmaking raw materials. The United States was estimated to have produced 2.0% and consumed 1.6%

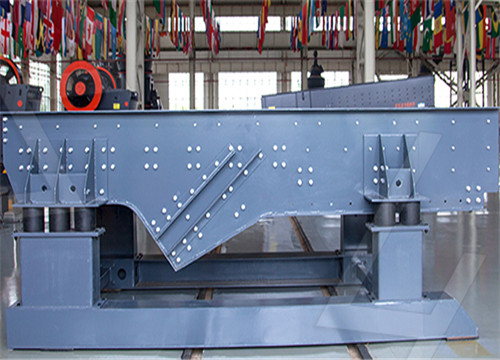

CrushingScreening Plants, Industrial Screening Plants, Mobile

Our offered range of Screening Plants is ideally used in road construction project or patch repair works made of superior quality these plants generally separates finer material from the heterogeneous mixture of coarse material. We also provide customization to the products with respect to application, capacity and site conditions. Ask for Price

Ore Sintering an overview ScienceDirect Topics

2010年4月2日Iron ore sintering is a material preparation process employed worldwide in the production of iron and steel. According to statistical data on pollution, sintering plants rank second in terms of toxic emissions, after the incineration of municipal solid waste (Menad et al., 2006; Remus et al., 2013 ).

Screening Plant an overview ScienceDirect Topics

A. Jankovic, in Iron Ore, 2015 8.2.4 Mobile crushing and screening plant applications for small- to medium-sized iron ore projects There is now a new generation of mobile crushing and screening plant systems, which have been developed based on the motivation of reducing truck haulage.

Iron Ore Screening Multotec

Iron ore screening equipment from Multotec is made from polyurethane or rubber screening media. Our screening equipment is ideal for high, medium or low grade profiles, reduce plant footprint by more than 33% and materials of construction ensure a long life at reduced cost with low maintenance requirements.

Iron ore pelletizing Metso Outotec

Our iron ore pelletizing systems combine the best features of both technologies to provide the most modern plant and to produce pellets at the lowest cost and highest quality. Pellet plants sized from 1.2MTPA to

Iron ore processing plant CDE Asia

Processed Iron Ore increases campaign life. Fine particles and Alumina in the feed end up as accretions in the kiln walls. Lower Alumina in the feed means a considerable reduction in cleaning and maintenance of the

Screening 101 Mineral ProcessingMetallurgy

2016年6月10日Screening 101. Screening is the passing of material through definite and uniform apertures is the only true and accurate means of grading to a required particle size. Air separation and hydraulic

MOBISCREEN MS EVO screening plants hit the mark

2021年8月6日More than 20 excavators are deployed for extraction, handling and loading of the ore, with 140 large dump trucks transporting the material from the mines for further processing by the screening plants.

Sintering: A Step Between Mining Iron Ore and

2019年6月11日Seven open-pit iron ore mines (each with associated concentration and pelletizing plants), and three iron metallic plants—one direct-reduced iron (DRI) plant and two hot-briquetted iron (HBI)

mpl screening plants for iron ore mining in Odisha

mpl screening plants for iron ore mining in Odisha. May 08,2021. India is bestowed with large reserves of iron ore and it is the second largest producer of steel across the globe. India’s total iron ore production for the year CY19 was 231 million MTs which enabled 90 per cent (111 million MTs) of steel production.

Godawari Power and Ispat Limited Iron Ore Crushing

Godawari Power and Ispat Limited Iron Ore CrushingScreening Unit 6 of 28 2008 Setting up of Iron Ore Crushing Plant at Gidhali of 12,00,000 TPA capacity. 2009 Iron Ore mining operations started at Ari Dongri, Dist. Kanker. 2009 Further expansion for installation of 20 MW Biomass Power Plant, Iron Ore Beneficiation -10,00,000 TPA, Rolling

Screening and crushing plant #iron_ore #steel_plant YouTube

2023年3月10日About Press Copyright Contact us Creators Advertise Developers Terms Privacy Press Copyright Contact us Creators Advertise Developers Terms Privacy

Ore Sintering an overview ScienceDirect Topics

2010年4月2日Iron ore sintering is a material preparation process employed worldwide in the production of iron and steel. According to statistical data on pollution, sintering plants rank second in terms of toxic emissions, after the incineration of municipal solid waste (Menad et al., 2006; Remus et al., 2013 ).

# 1 CrushingScreening Plant in India Torsa

Iron ore crushing and screening for steel industry; Limestone crushingscreening for cement industry; Torsa is the biggest crushingscreening plants in India who specialize in producing stone crushers, cone crushers and automatic crushing plants. info@torsa Toll Free : 1800 121 5696

Beneficiation of Iron Ore Mineral ProcessingMetallurgy

2016年5月24日Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice.This also applies to iron ores of the non-magnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per

Wiluna West JWD Iron Ore Project, Australia

2021年9月22日The run-of-mine (ROM) ore is hauled to the ROM stockpile from where it is fed to the primary crusher via a front-end loader. A mobile crushing and screening plant is located near the mine site to provide primary, secondary, and tertiary crushing and screening to produce lump and fine products.