Components Of A Hydrocone Mining Mill

Sandvik® Hydrocone®Superior® Crushers parts

Replacing parts is a drag on your business. Maintenance down time eats away at your throughput, and replacement components can be a significant investment — especially

进一步探索

Parts for crushers spare and wear parts Metso OScreeningCrusher Replacement Screens S根据热度为您推荐•反馈

Cone Crusher Parts Mineral ProcessingMetallurgy

2017年2月19日The Mantalloy head mantle of this cone crusher is a replaceable wearing surface. It is made of alloyed manganese steel, and

Grinding mills for mining and minerals processing

Metso Outotec has over 100 years of experience in horizontal grinding mills and has always been an industry-leader in innovative technology. Metso Outotec's unmatched expertise

Crushing Metso Outotec

Metso Outotec is combining our legacy and expertise to introduce the Mining Crushing Stations. These 2 modular crushing and screening plants are unique, cost-efficient and

Theory Of Hydrocone Crusher

Cone Crushers Document Summary mining research library . For example, a Model 10-84 Hydrocone crusher has an 84-in. diam man¬tle, and is capable of accepting a 10

Construction Working and Maintenance of Practical

Construction Working and Maintenance of Practical Maintenance

Components Of A Hydrocone Gold Ore kanjeevaramsilks

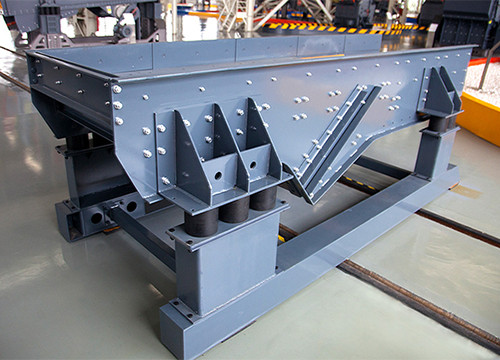

Components Of A Hydrocone Shaking Table In Madhya. components of a hydrocone shaking table in madhya. We have madhya pradesh gold ore shake table ,Some of the

Mponents Of A Hydrone Crusher

The Raymond grinding mill was ever popular in mining, building materials, chemical engineering and metallurgy industries Raymond Mill Portable mobile jaw crusher is

ore dressing ore components of a hydrocone ball mill

Iron Extraction by Blast Furnace Metallurgy . 1 Crushing and grinding The crushing of ores into a fine powder in a crusher or ball mill is the first step of Metallurgy 2 The

Grinding mills for mining and minerals processing Metso Outotec

Horizontal Mill Plant Units offer complete support in grinding circuit selection, as well as execution, service and operation. Read more Grinding parts and services Grinding mill parts Customized grinding mill parts including heads, shells, trunnions and liners, main bearings, gears and pinions, and more! Mill liners

Crushing Metso Outotec

Metso Outotec is combining our legacy and expertise to introduce the Mining Crushing Stations. These 2 modular crushing and screening plants are unique, cost-efficient and productive, and designed to provide significant time and resource savings. The Mining Crushing Stations are made up of 2 solutions: FIT™ Stations and Foresight™ Stations.

AMIT 135: Lesson 6 Grinding Circuit Mining Mill Operator

Objectives. At the end of this lesson students should be able to: Explain the grinding process. Distinguish between crushing and grinding. Compare and contrast different type of equipment and their components used for grinding. Identify key variables for process control. Design features of grinding equipment (SAG, BALL and ROD MILLS)

SAG Mill Components Mineral ProcessingMetallurgy

2018年4月18日Mill heads are key structural components of any grinding mill. They must carry the load of the shell assembly, liners, media and material in process, and transmit it evenly to the trunnion bearings to assure smooth operation. Manufacturers in the “big mill business” have long ago recognized that simple extrapolation of existing designs from

Construction Working and Maintenance of Practical Maintenance

Construction Working and Maintenance of Practical Maintenance

Semi-autogenous grinding (SAG) mill liner design and

in variable speed mills, this may be achieved by reducing mill speed; and in both cases this may be achieved by design by increasing the lifter face angle. Traditionally, the number of shell lifters used in a SAG mill is equal to twice the number of the feet in the mill shell diameter (e.g., a 34-ft-diameter mill shell would have 68 shell lifters).

Pennsylvania Crusher Handbook of Crushing TerraSource Global

Pennsylvania Crusher Handbook of Crushing TerraSource Global

Radioactive Waste From Uranium Mining and Milling US EPA

2022年7月29日Milling: This process takes place at a mill after the ore containing uranium is removed from the Earth through open pit or underground mining. The ore is brought to a mill, crushed, and ground up before chemicals are added to dissolve the uranium. The uranium is then separated from the chemical solution, solidified, dried and packaged.

components of hydrocone crusher

2008. 7. 4. 2.2 Today’s construction of the Hydrocone crusher The Hydrocone crusher and its basic functions are described in chapter 2.2. 2.2.1 Mechanics Figure 2 below shows a picture of the Hydrocone crusher. In the center of the Hydrocone crusher is the main shaft (1). The main shaft can be positioned with the hydroset cylinder (4)

ore dressing ore components of a hydrocone ball mill

Iron Extraction by Blast Furnace Metallurgy . 1 Crushing and grinding The crushing of ores into a fine powder in a crusher or ball mill is the first step of Metallurgy 2 The concentration of ores The next process of Metallurgy to separate impurities from ore is known as a concentration of minerals or ore dressing 3

Crusher Wikipedia

A feeder device such as an apron feeder, conveyoror vibrating grid controls the rate at which this material enters the crusher, and often contains a preliminary screening device which allows smaller material to bypass the crusher itself, thus improving efficiency.

components of a hydrocone crusher,

Hydrocone Crusher Components therapiehildebrandtde. Hydrocone Crusher Components The hydrocone cone crusher is the logical outgrowth, a crusher having a means of rapidly changing product size or compensating for wear on the crushing surfaces a crusher which produces a better, more cubical product than any comparable crusher and

AMIT 135: Lesson 7 Ball MillsCircuits Mining Mill Operator

Objectives. At the end of this lesson students should be able to: Explain the role of ball mill in mineral industry and why it is extensively used. Describe different types of ball mill design. Describe the components of ball mill. Explain their understanding of ball mill operation. Explain the role of critical speed and power draw in design

components of a hydrocone crusher

weight of hydrocone crushers knowledgecloudincomponents of a hydrocone crusher fordsburginncoza. components of a hydrocone crusher use of h hydrocone crusher Request for Quotation You can get the price list and a GME representative will contact you contact svedala cone crusher May 6 grinding mill businesses and Svedala s worldwide

Crusher Wikipedia

A feeder device such as an apron feeder, conveyoror vibrating grid controls the rate at which this material enters the crusher, and often contains a preliminary screening device which allows smaller material to bypass the crusher itself, thus improving efficiency.

Crushing Metso Outotec

The Mining Crushing Stations are made up of 2 solutions: FIT™ Stations and Foresight™ Stations. FIT™ Stations are focused on speed and flexibility for quick installations. The Foresight™ Stations are focused on smart controls and automation for optimal productivity.

AMIT 135: Lesson 6 Grinding Circuit Mining Mill Operator

Objectives. At the end of this lesson students should be able to: Explain the grinding process. Distinguish between crushing and grinding. Compare and contrast different type of equipment and their components used for grinding. Identify key variables for process control. Design features of grinding equipment (SAG, BALL and ROD MILLS)

AMIT 135: Lesson 7 Ball MillsCircuits Mining Mill Operator

Objectives. At the end of this lesson students should be able to: Explain the role of ball mill in mineral industry and why it is extensively used. Describe different types of ball mill design. Describe the components of ball mill. Explain their understanding of ball mill operation. Explain the role of critical speed and power draw in design

SAG Mill Components Mineral ProcessingMetallurgy

2018年4月18日Mill heads are key structural components of any grinding mill. They must carry the load of the shell assembly, liners, media and material in process, and transmit it evenly to the trunnion bearings to assure smooth operation. Manufacturers in the “big mill business” have long ago recognized that simple extrapolation of existing designs from

Semi-autogenous grinding (SAG) mill liner design and

in variable speed mills, this may be achieved by reducing mill speed; and in both cases this may be achieved by design by increasing the lifter face angle. Traditionally, the number of shell lifters used in a SAG mill is equal to twice the number of the feet in the mill shell diameter (e.g., a 34-ft-diameter mill shell would have 68 shell lifters).

Pennsylvania Crusher Handbook of Crushing TerraSource Global

Pennsylvania Crusher Handbook of Crushing TerraSource Global

Radioactive Waste From Uranium Mining and Milling US EPA

2022年7月29日Milling: This process takes place at a mill after the ore containing uranium is removed from the Earth through open pit or underground mining. The ore is brought to a mill, crushed, and ground up before chemicals are added to dissolve the uranium. The uranium is then separated from the chemical solution, solidified, dried and packaged.

components of hydrocone crusher

2008. 7. 4. 2.2 Today’s construction of the Hydrocone crusher The Hydrocone crusher and its basic functions are described in chapter 2.2. 2.2.1 Mechanics Figure 2 below shows a picture of the Hydrocone crusher. In the center of the Hydrocone crusher is the main shaft (1). The main shaft can be positioned with the hydroset cylinder (4)

ore dressing ore components of a hydrocone ball mill

Iron Extraction by Blast Furnace Metallurgy . 1 Crushing and grinding The crushing of ores into a fine powder in a crusher or ball mill is the first step of Metallurgy 2 The concentration of ores The next process of Metallurgy to separate impurities from ore is known as a concentration of minerals or ore dressing 3

components of a hydrocone crusher,

Hydrocone Crusher Components therapiehildebrandtde. Hydrocone Crusher Components The hydrocone cone crusher is the logical outgrowth, a crusher having a means of rapidly changing product size or compensating for wear on the crushing surfaces a crusher which produces a better, more cubical product than any comparable crusher and

Gearless mill drives Grinding ABB Mining

Maximum availability and productivity. Go gearless to meet your business objetives by exceeding standard availability targets in your grinding operations. ABB’s GMD is the most powerful mill drive system in the market to power semiautogenous (SAG), ball and autogenous (AG) mills, This ’workhorse’ for grinding operations combines a robust

Construction Working and Maintenance of Practical

Construction Working and Maintenance of Practical Maintenance

Rock Crushers, Stone Crushers, Screening and Crushing Equipment

Our extensive expertise ranges from greenfield mining projects to expansions, and individual or multi-equipment replacement projects. We also supply key genuine components and a wide range of crushing and screening wear parts. crushing and screening equipment is designed to help keep operators and maintenance