Wet Vibrating Screen High Frequency

High Frequency Screens Astec

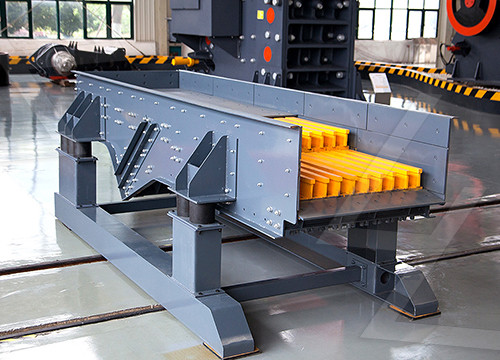

Astec high frequency screens utilize high-speed vibration, from 3600 4200 RPM, directly induced to the screen media, allowing for increased stratification and material separation. The directly-induced vibration improves screen efficiency at high production

进一步探索

TCI Manufacturing › High Frequency ScreensMobile High Frequency Screen Plants AstecKpi-Jci High Frequency Screens Alta Equipment6′ X 12′ PEP VARI-VIBE 2 HIGH FREQUENCY SCREENUsed High Frequency Screens for sale. MSL equipmentm根据热度为您推荐•反馈

High-frequency vibrating screens Wikipedia

OverviewNew developmentRange of applicationsAdvantages and limitationsAvailable designsMain process characteristicsCharacteristics assessmentPossible heuristics to be used during design of the process

The research on high frequency screens has led to new developments in the field which enhance the operation and performance of the equipment. These new developments include the stacking of up to 5 individual screen decks placed on top of the other and operating in parallel. A divider system splits the feed slurry to each Stack Sizer screen, then to each screen deck on the machine. Each screen deck has an undersize and oversize collection pan which will respectivel

Derrick Corporation Solids Control and Fine Wet / Dry

根据热度为您推荐•反馈

Multi Deck High Frequency Screen H-Screening

H-Screening offers high frequency fine screen stakck sizer, linear vibrating screens for fine screening and wet processing, dewatering

Screening machines for wet screening RHEWUM

Dewatering, classification or cleaning with screening machines. Many processing tasks require the use of wet screening. In suspension, the product is fed through a suitable

high frequency vibrating screen and dewatering screen HUATAO

2022年2月14日The high-frequency vibrating screen usually operates at an inclination angle of 0-25°, and its inclination angle can sometimes be as high as 45 degrees. In the

A review of process models for wet fine classification with high

2021年12月1日Selected models are detailed and used to describe a high frequency screen trials database, to help identify the advantages and disadvantages offered by

High frequency vibration screen/Wet sieve machine

2021年4月27日High frequency vibration screen/Wet sieve machine YouTube This video show the structure and working principle of high frequency vibrating screen. It

Portable Vibratory Separator Vibro Filter Sieve Machine

Features of Portable High Frequency Vibro Filter Sieve Machine for Ceramic Industry: 1. High vibration frequency and low amplitude can effectively reduce the surface tension of the pulp, which is conducive to

High Frequency Rotary Sifter Machine Stainless Steel

Stainless Steel High Frequency Vibrating Filter Sieve for Ceramic Glazes is widely used in dry-wet filter, grading and dewatering of various materials in ceramics, chemical industry, brick making, , pharmacy, chemical

A review of process models for wet fine classification with high

2021年12月1日1. Introduction. Vibrating screens are one of the most important and versatile devices in mineral processing plants. They are responsible for size classification at operations ranging from crushing facilities to final product separation [].Screening technology has developed to be able to classify coarse to very fine particles using screen openings

Stack Sizer, High Frequency Vibrating Fine Screen

Stack Sizer efficient, fine particle wet screening, high frequency vibrating screens. H-Screening Stack Sizer is purpose-designed for efficient fine particle wet screening. It can be built up to 5 decks

VIBFEM M Sand High Frequency Screen, Vibrating

We offer M sand High Frequency Screen (VIBFEM HFF Screen) for manufacturing construction sand as per IS 383 Zone II and plaster sand as per IS 1542. Very fine silt -150 micron is removed from manufactured

Simulation of particles motion on a double vibrating flip-flow screen

2023年3月8日The surfaces of vibrating flip-flow screens have the advantages of high vibration intensity, non-blocking holes, easy depolymerization of clustered particles, and self-cleaning functionality, which are widely used in the classification of wet fine-grained granular materials.

Rectangular Type Wet Screening Equipment Equipped

High Light: wet vibrating screen, sieve separator machine: Rectangular Type Wet Screening Equipment Equipped With Cleaning Nozzles . Feature: high-frequency vibration. Exciting Force: 3KN~15KN.

High frequency vibration screen/Wet sieve machine YouTube

2021年4月27日This video show the structure and working principle of high frequency vibrating screen. It only have 1 layer,1 inlet and 1 outlet,3 wheels for easy movable.T...

High Frequency Vibrating Screen-DAHAN Vibration Machinery

The high frequency vibrating screen uses a high-frequency motor, that is, a 2-stage motor (speed is 3000r/min) as the excitation source to destroy the tension of water molecules in the slurry. The high-frequency vibration makes the slurry smaller than the mesh hole pass through the screen and enter the lower layer The screen frame is

high frequency vibrating screen and dewatering screen

2022年2月14日The high-frequency vibrating screen usually operates at an inclination angle of 0-25°, and its inclination angle can sometimes be as high as 45 degrees. In the case of proper feeding particle size and concentration, and the difference between the required sieve particle size and the feed particle size is not more than 30%, the screening

High Frequency Rotary Sifter Machine Stainless Steel

Stainless Steel High Frequency Vibrating Filter Sieve for Ceramic Glazes is widely used in dry-wet filter, grading and dewatering of various materials in ceramics, chemical industry, brick making, , pharmacy, chemical

Full range of BRU Vibrating Screens

The BRU Vibrating Screen is designed with durability and ease of use as a central focus. And, by improving performance and throughout, you can enjoy better throughput for your equipment. Usable in most applications, these screens come in a wide range of sizes, from 0.9m to 4.8m wide and up to 11.0m long.

Screening machines for wet screening RHEWUM

Dewatering, classification or cleaning with screening machines. Many processing tasks require the use of wet screening. In suspension, the product is fed through a suitable feeding system (syphon, overflow pipe or similar) onto the screen width. The liquid used depends on the product, and as it passes along the mesh it transports the fine

vibrating sieve,vibrating screen,gyratory screen,tumbler screen, wet

Stainless High-efficiency Linear Vibrating Screen for Sugar. 1500*3000mm stainless steel double-deck high-efficiency rectangular linear vibrating screen separator Read More.. Address : NO. 268, Xima Avenue, Fengquan District, Xinxiang, Henan, China. Phone : +86-156 3736 1027.

Efficient Material Separation Sifter Soda Ash Linear Vibrating

Efficient Material Separation Sifter Soda Ash Linear Vibrating Screening Machine,Find Complete Details about Efficient Material Separation Sifter Soda Ash Linear Vibrating Screening Machine,Efficient Material Separation Sifter,Soda Ash Linear Vibrating Screen,Linear Vibrating Screening Machine from Supplier or Manufacturer-Xinxiang

What is the difference between a high frequency vibrating screen

2022年1月14日It can be used to screen wet or dry materials. The high-frequency vibrating screen usually operates at an inclination angle of 0-25°, and its inclination angle can sometimes be as high as 45 degrees.

A review of process models for wet fine classification with high

2021年12月1日1. Introduction. Vibrating screens are one of the most important and versatile devices in mineral processing plants. They are responsible for size classification at operations ranging from crushing facilities to final product separation [].Screening technology has developed to be able to classify coarse to very fine particles using screen openings

Stack Sizer, High Frequency Vibrating Fine Screen

Stack Sizer efficient, fine particle wet screening, high frequency vibrating screens. H-Screening Stack Sizer is purpose-designed for efficient fine particle wet screening. It can be built up to 5 decks

Simulation of particles motion on a double vibrating flip-flow screen

2023年3月8日The surfaces of vibrating flip-flow screens have the advantages of high vibration intensity, non-blocking holes, easy depolymerization of clustered particles, and self-cleaning functionality, which are widely used in the classification of wet fine-grained granular materials.

Rectangular Type Wet Screening Equipment Equipped

High Light: wet vibrating screen, sieve separator machine: Rectangular Type Wet Screening Equipment Equipped With Cleaning Nozzles . Feature: high-frequency vibration. Exciting Force: 3KN~15KN.

VIBFEM M Sand High Frequency Screen, Vibrating

VIBFEM HFF Screen can be fitted in any existing crushing plant to process sand and remove silt. It is Australian technology manufactured in Maharashtra India . We focus on efficiency and quality of sand. We give

High frequency vibration screen/Wet sieve machine YouTube

2021年4月27日High frequency vibration screen/Wet sieve machine YouTube This video show the structure and working principle of high frequency vibrating screen. It only have 1 layer,1 inlet...

High Frequency Vibrating Screen-DAHAN Vibration Machinery

High frequency Not clogged Designed for liquids Screen diameter: 600mm, 800mm, 1000mm, 1200mm Mesh size: 0.01~5mm Vibration Frequency: 3000rpm/min Power: 0.25-0.4KW (Level 2 Motor) Capacity: 200-1200 Liter/hour Voltage: 200-400 v Dimension (L*W*H): 100*80*110 cm Weight: 90 Kg

high frequency vibrating screen and dewatering screen

2022年2月14日The high-frequency vibrating screen usually operates at an inclination angle of 0-25°, and its inclination angle can sometimes be as high as 45 degrees. In the case of proper feeding particle size and concentration, and the difference between the required sieve particle size and the feed particle size is not more than 30%, the screening

High Frequency Rotary Sifter Machine Stainless Steel

Stainless Steel High Frequency Vibrating Filter Sieve for Ceramic Glazes is widely used in dry-wet filter, grading and dewatering of various materials in ceramics, chemical industry, brick making, , pharmacy, chemical

Screening machines for wet screening RHEWUM

Dewatering, classification or cleaning with screening machines. Many processing tasks require the use of wet screening. In suspension, the product is fed through a suitable feeding system (syphon, overflow pipe or similar) onto the screen width. The liquid used depends on the product, and as it passes along the mesh it transports the fine

Efficient Material Separation Sifter Soda Ash Linear Vibrating

Efficient Material Separation Sifter Soda Ash Linear Vibrating Screening Machine,Find Complete Details about Efficient Material Separation Sifter Soda Ash Linear Vibrating Screening Machine,Efficient Material Separation Sifter,Soda Ash Linear Vibrating Screen,Linear Vibrating Screening Machine from Supplier or Manufacturer-Xinxiang

vibrating sieve,vibrating screen,gyratory screen,tumbler screen, wet

Stainless High-efficiency Linear Vibrating Screen for Sugar 1500*3000mm stainless steel double-deck high-efficiency rectangular linear vibrating screen separator Read More.. Address : NO. 268, Xima Avenue, Fengquan District, Xinxiang, Henan, China Phone : +86-156 3736 1027 Email : sale@aarealmachine Monday Friday : 8:00 am 5:00 pm

What is the difference between a high frequency vibrating screen

2022年1月14日It can be used to screen wet or dry materials. The high-frequency vibrating screen usually operates at an inclination angle of 0-25°, and its inclination angle can sometimes be as high as 45 degrees.

Agriculture Free Full-Text Process Analysis and Parameters

The application of the conventional vibrating screen to the separation of the black soldier fly (BSF) sand mixture has several problems (e.g., high rate of impurity and low efficiency). A two-stage sieve surface vibratory sorting device with combined planar and curved surfaces was investigated, and its critical operating parameters were determined. Moreover, a