Brief Introduction About Processing Of Copper

Copper processing Roasting, smelting, and converting

Copper processing Roasting, smelting, and converting Britannica Home Technology Industry copper processing Roasting, smelting, and converting Once a concentrate has been produced containing copper and other

Copper processing Ores Britannica

根据热度为您推荐•反馈

Copper extraction Wikipedia

OverviewConcentration (beneficiation)HistoryRoastingRefiningConcentrate and copper marketingSee alsoBibliography

The average grade of copper ores in the 21st century is below 0.6% copper, with a proportion of economic ore minerals being less than 2% of the total volume of the ore rock. Thus, all mining operations, the ore must usually be beneficiated (concentrated). The concentrate is typically sold to distant smelters, although some large mines have smelters located nearby. Such colocation of

Innovations: Introduction to Copper: Types of Copper

The most important alloy of nickel with copper, known as Monel metal, contains about 30-35% copper. It is highly resistant to many forms of corrosion, especially in chemical processing and marine applications.

COPPER: A BRIEF INTRODUCTION conduitir

substantial expenses. In terms of copper, anything over 100m and 1% copper equivalent is high-grade2, but a deposit between 0.5% and 2$ copper is acceptable for commercial

Copper Alloys an overview ScienceDirect Topics

Copper alloys are generally used as lead-frame material because of their high electronic conductivity, thermal transfer property, and corrosion resistance. During the

Brief introduction of production process of red copper tube

Production process of tungsten-copper alloy Dec .27.2022 The technical process of preparation of tungsten-copper alloy by powder metallurgy is made by mixing of powder

Brief Introduction: Tungsten Copper EDM electrodes in EDM

What is EDM Processing? EDM processing is carried out in a liquid medium. The automatic feed adjustment device of the machine tool keeps a proper discharge gap

Processing of Complex Materials in the Copper

2020年7月6日With the gradual decrease in the grade of copper ores being processed, copper concentrates have become more complex with higher impurity and gangue content. This trend has had a detrimental

Copper processing Roasting, smelting, and

Copper processing Roasting, smelting, and converting Britannica Home Technology Industry copper processing Roasting, smelting, and converting Once a concentrate has been produced containing copper

Copper processing Ores Britannica

The first step, mineral processing, is to liberate the copper minerals and remove waste constituents—such as alumina, limestone, pyrite, and silica—so that the copper minerals and other nonferrous minerals of

Copper extraction Wikipedia

Copper extraction refers to the methods used to obtain copper from its ores. The conversion of copper ores consists of a series of physical, chemical and electrochemical processes. Lime is used to raise the pH of the water bath, causing the collector to bond more efficiently to the copper sulfides. The process can produce a concentrates

Innovations: Introduction to Copper: Types of Copper

The most important alloy of nickel with copper, known as Monel metal, contains about 30-35% copper. It is highly resistant to many forms of corrosion, especially in chemical processing and marine applications.

Copper Alloys an overview ScienceDirect Topics

Copper alloys are generally used as lead-frame material because of their high electronic conductivity, thermal transfer property, and corrosion resistance. During the manufacturing process of lead frame, copper alloys are bent, coated, and etched.

EXTRACTION OF COPPER University of Technology, Iraq

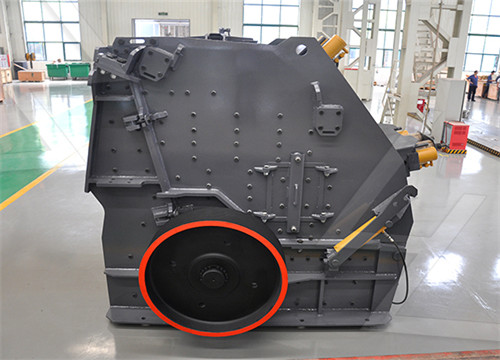

Ores containing 4% or more copper are treated by smelting process. Very poor ores are treated by hydro-metallurgical process. EXTRACTION OF COPPER BY SMELTING PROCESS Following steps are involved in the extraction of copper. Crashing and Grinding The ore is crushed then ground into powder. CONCENTRATION-Floatation process.

Brief introduction of production process of red copper tube

Deform-2d simulation software was used to simulate and analyze the extrusion process parameters, such as billet temperature and extrusion speed, in order to manufacture an ultra-thick seamless T2 copper tube with uniform and fine grains for large size crystallizer (crucible). The results show that the temperature distribution and deformation degree of

Innovations: Brief Early History of Brass Copper

The vapor from the zinc permeated the copper to form brass, which could then be melted to give a uniform alloy. Only in the last millennium has brass been appreciated as an engineering alloy. Initially, bronze was easier to make using native copper and tin and was ideal for the manufacture of utensils.

A Brief Review on Synthesis and Characterization of

2016年7月9日A further increase in the sintering temperature leads to an intensification of the MAX phase decomposition process, and at a lower sintering temperature, the copper matrix remains incompletely formed.

Copper Wire an overview ScienceDirect Topics

When copper wire is made, it is drawn through a series of dies which makes the wire thinner (and longer of course). In the American Wire Gauge (AWG), after passing through the first die it has a diameter of 7.34 mm (0.289 inches). This size wire is then called 1 AWG.

Brief introduction of Chile’s copper mine

2016年1月18日Brief introduction of Chile’s copper mine In 2015,the copper price plummeted, the "Copper Kingdom" -Chile has not escaped the impact, many companies have postponed their projects...

Plasmonic Copper Sulfide-Based Materials: A Brief Introduction

2017年5月17日Plasmonic copper sulfide-based colloidal nanocrystals (NCs) have attracted considerable attention due to their unique and versatile optical and electronic properties. In this Feature Article, we first introduce the optical properties of these p-type semiconductor nanostructures, particularly localized surface plasmon resonance (LSPR).

Copper processing Roasting, smelting, and

Copper processing Roasting, smelting, and converting Britannica Home Technology Industry copper processing Roasting, smelting, and converting Once a concentrate has been produced containing copper

Processing of Complex Materials in the Copper

2020年7月6日With the gradual decrease in the grade of copper ores being processed, copper concentrates have become more complex with higher impurity and gangue content. This trend has had a detrimental

Copper extraction Wikipedia

Copper extraction refers to the methods used to obtain copper from its ores. The conversion of copper ores consists of a series of physical, chemical and electrochemical processes. Lime is used to raise the pH of the water bath, causing the collector to bond more efficiently to the copper sulfides. The process can produce a concentrates

Innovations: Introduction to Copper: Types of Copper

The most important alloy of nickel with copper, known as Monel metal, contains about 30-35% copper. It is highly resistant to many forms of corrosion, especially in chemical processing and marine applications.

EXTRACTION OF COPPER University of Technology, Iraq

Ores containing 4% or more copper are treated by smelting process. Very poor ores are treated by hydro-metallurgical process. EXTRACTION OF COPPER BY SMELTING PROCESS Following steps are involved in the extraction of copper. Crashing and Grinding The ore is crushed then ground into powder. CONCENTRATION-Floatation process.

A Brief Review on Synthesis and Characterization of

2016年7月9日A further increase in the sintering temperature leads to an intensification of the MAX phase decomposition process, and at a lower sintering temperature, the copper matrix remains incompletely formed.

Brief introduction of production process of red copper tube

Deform-2d simulation software was used to simulate and analyze the extrusion process parameters, such as billet temperature and extrusion speed, in order to manufacture an ultra-thick seamless T2 copper tube with uniform and fine grains for large size crystallizer (crucible). The results show that the temperature distribution and deformation degree of

Brief introduction of Chile’s copper mine

2016年1月18日Brief introduction of Chile’s copper mine In 2015,the copper price plummeted, the "Copper Kingdom" -Chile has not escaped the impact, many companies have postponed their projects...

Brief Introduction: Tungsten Copper EDM electrodes in EDM Processing

What is EDM Processing? EDM processing is carried out in a liquid medium. The automatic feed adjustment device of the machine tool keeps a proper discharge gap between the workpiece and the tool electrode. When a strong pulse voltage is applied between the tool electrode and the workpiece (to reach the medium in the gap)

60 Centuries of Copper: Introduction

2013年8月12日Copper was the first metal used by man in any quantity. The earliest workers in copper soon found that it could be easily hammered into sheets and the sheets in turn worked into shapes which became more complex as their skill increased. After the introduction of bronze, a wide range of castings also became possible.

JMMP Free Full-Text High-Precision Adjustment of Welding

2021年11月25日Copper bonds are suitable for cell contacting due to their high electrical and thermal conductivity but cannot be processed in conventional ultrasonic joining due to their high thermal conductivity [ 3 ]. Laser beam micro welding offers a highly automatable, contactless joining method whereby copper bonds can be processed.

Copper Wire an overview ScienceDirect Topics

John Crisp, in Introduction to Copper Cabling, 2002. American Wire Gauge. When copper wire is made, it is drawn through a series of dies which makes the wire thinner (and longer of course). In the American Wire Gauge (AWG), after passing through the first die it has a diameter of 7.34 mm (0.289 inches). This size wire is then called 1 AWG.

Sensors Free Full-Text Characterizations and Electrical Modelling

2016年1月5日CuO and V2O5 graphene quantum tunneling composites (GQTC) presented in this article were produced and their sensory properties were analyzed. The composites were synthesised using two stage high-power milling process, which resulted in materials that have good temeprature and pressure sensory properties. Described production