Gold Mining Solution

Cyanide Use in Gold Mining Earthworks

A sodium cyanide solution is commonly used to leach gold from ore. There are two types of leaching: Heap leaching: In the open, cyanide solution is sprayed over huge heaps of crushed ore spread atop giant collection

Technical Solutions planetGOLD

Access to finance makes possible safer solutions to gold processing, which in turn improves the livelihoods of the mining communities. The gap in applicable guidance

In situ leach Wikipedia

OverviewMineralsProcessEnvironmental concernsSee alsoExternal links

In-situ leach is widely used to extract deposits of water-soluble salts such as potash (sylvite and carnallite), rock salt (halite), sodium chloride, and sodium sulfate. It has been used in the US state of Colorado to extract nahcolite (sodium bicarbonate). In-situ leaching is often used for deposits that are too deep, or beds that are too thin, for conventional underground mining.

Gold Precipitation Methods Mineral Processing

2016年7月27日The first essential to in any methods for effective Gold Precipitation is clear solution. Regardless of color, the solution must be

Gold Mine Problem GeeksforGeeks

2023年2月6日Gold Mine Problem Try It! Method 1: Recursion A simple method that is a direct recursive implementation C++ Java Python3 C# Javascript

33 Causes, EffectsSolutions for Mining E&C

In-situ mining In-situ mining is used to obtain uranium. Along with the uranium, additional elements like selenium, arsenic or lead are also extracted. Placer mining Placer mining

Gold Mining Codechef Solution Brokenprogrammers

Mining gold is a continuous process, i.e. if a miner works for tt days (where tt is a real number) in a mine where this miner has mining speed gg gold per day, then he will

Mining Solutions Draslovka

Mining Solutions A lack of reliable sodium cyanide supply, updated employee safety protocols, and efficient operational procedures leads to production downtime. The

Gold Mining CodeChef Solution queslers

2023年1月18日Gold Mining CodeChef Solution in PYTH “ ” t = int (raw_input ()) for i in range (t): N = int (raw_input ()) at = 0 bt = 0 for k in range (N): st = raw_input ().split () G

How to Advance Sustainable Mining International Institute for

2021年10月18日Finally, the 2013 Minamata Convention on Mercury addresses the use of mercury in artisanal and small-scale gold mining (ASGM). These miners, primarily in developing countries, use mercury to extract gold from ore because it is relatively inexpensive and easy to use. There is a need for more innovative solutions to

The gold industry in 2019 McKinsey

2019年4月12日Advanced analytics, when applied to exploration, means that companies will be able to assess a wide range of data sources including drill logs, geological models, and unstructured map analysis

Gold cyanidation Wikipedia

Gold cyanidation (also known as the cyanide process or the MacArthur-Forrest process) is a hydrometallurgical technique for extracting gold from low-grade ore by converting the gold to a water-soluble coordination complex.It is the most commonly used leaching process for gold extraction. Cyanidation is also widely used in the extraction of silver, usually after

Gold Fields Reduces Control System Risk With New Mining Solution

2015年2月2日The mining solution using PlantPAx removes unnecessary operational complexity as interlocking descriptions and tags are standardised to be intuitive. This reduction in complexity means that Gold Fields requires fewer highly skilled operators, addressing a common industry problem of applicable skills shortage.

Bluebird announces scoping study for South Korean gold projects

2 Bluebird Merchant Ventures Ltd, a gold company primarily focused on bringing historic mines back into production, has announced a scoping study for its Kochang and Gubong gold projects in South Korea. Summary: Results of the study show excellent initial validation of the projects’ economic potential. At US$1750 gold price, for production from

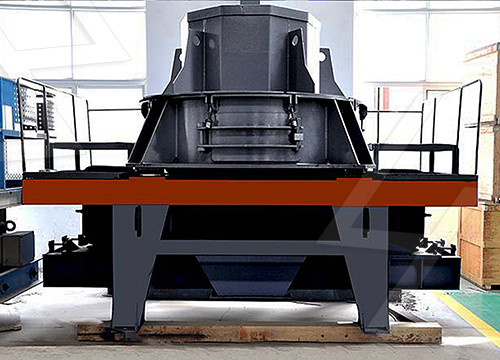

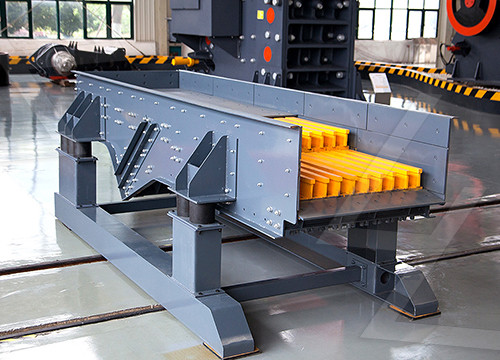

Hard Rock Gold Mining Mineral Processing

The hard rock gold (vein gold ) mining plant flow can be roughly divided into crushing, screening, grinding and separation.JXSC Mining Machinery is committed to providing customizable hard rock gold processing plant

Cip System, Cip Process, Cip Gold Processing Xinhai

Xinhai CIP Production Line has helped hundreds of mines to get gold. Our gold production process and gold recovery methods are based on rich experience. marketing@ytxinhai. 0086 . Language.

Gold Mining Codechef Solution Brokenprogrammers

Mining gold is a continuous process, i.e. if a miner works for tt days (where tt is a real number) in a mine where this miner has mining speed gg gold per day, then he will mine g⋅tg⋅t gold. Obviously, it is impossible to work in a mine after no gold remains in it.

Hitachi Construction Machinery and First Quantum Minerals

19 小时Kansanshi is a copper gold mine located near Solwezi in the North Western Province producing copper concentrate, anode and cathode. It has been in operation since 2005. It has two open pits as...

Gold mining at home,Easy solution by gold stone channel

2023年3月7日Extracting gold from stone is a special pleasure, and if you are looking for it, you can follow my channel. Do not use excess acid as it will spoil the work....

Gold Mining CodeChef Solution queslers

2022年12月26日Gold Mining CodeChef Solution in C++14 #include <iostream> using namespace std; int main () { // your code goes here int t,n,x,y; cin>>t; while (t--) { cin>>x>>y>>n; if ( (x+1)*n>=y) cout<<"YES"<<endl; else cout<<"NO"<<endl; } return 0; } Gold Mining CodeChef Solution in PYTH 3

Gold Mining: Why Clean Mining Is The Better Choice

In June 2022, Clean Mining signed a partnership with Gekko, a world technical leader in processing and low-energy mining solutions. Clean Mining solution in combination with Gekko’s world leading intensive leaching technologies (ILR) allows for gold processing to become more environmentally friendly, while achieving high recovery.

Gold processing Mining and concentrating Britannica

Gold can be freed from these ores or concentrates by treating them with various oxidizing processes. The most common method is to roast gold-bearing minerals at temperatures of 450° to 750° C (840° to 1,380° F) to destroy the interfering sulfides.

CIL Gold Mining Process, Equipment Mineral Processing

Carbon in Leach (CIL) process is widely used in the mining industry and in particular, it is an integral step of gold processing in gold extraction. Normally the CIL process can concentrate gold from 2.5–3.5 g/t in ore to 2000 to 6000 g/t on carbon. CIL gold process is suitable for the beneficiation of oxidized gold ore with low sulfur

How to Advance Sustainable Mining International Institute for

2021年10月18日The solution was to recast the mining business model as a development partnership, and to work with stakeholders to pursue shared goals. This initiative saw the development of joint regional plans among government, community, and mine partners, with the southern African region as one of the first to implement such an initiative.

Gold mining Wikipedia

Gold mining is the extraction of gold resources by mining. Historically, mining gold from alluvial deposits used manual separation processes, such as gold panning. Finely ground rock is treated with a solution of

The gold industry in 2019 McKinsey

2019年4月12日Advanced analytics, when applied to exploration, means that companies will be able to assess a wide range of data sources including drill logs, geological models, and unstructured map analysis

Clean Mining: Our Safe And Sustainable Solution To Gold Mining

Clean Mining: Our Safe And Sustainable Solution To Gold Mining Partner of Choice for the Gold Mining Industry Award-winning, effective and clean alternative solution for the Gold processing Learn More We are serving the Gold Mining Companies who are: Starting greenfield projects

Bluebird announces scoping study for South Korean gold projects

2 Bluebird Merchant Ventures Ltd, a gold company primarily focused on bringing historic mines back into production, has announced a scoping study for its Kochang and Gubong gold projects in South Korea. Summary: Results of the study show excellent initial validation of the projects’ economic potential. At US$1750 gold price, for production from

Hard Rock Gold Mining Mineral Processing

The hard rock gold (vein gold ) mining plant flow can be roughly divided into crushing, screening, grinding and separation.JXSC Mining Machinery is committed to providing customizable hard rock gold processing plant

Cip System, Cip Process, Cip Gold Processing Xinhai

Xinhai CIP Production Line has helped hundreds of mines to get gold. Our gold production process and gold recovery methods are based on rich experience. marketing@ytxinhai. 0086 . Language.

Hitachi Construction Machinery and First Quantum Minerals

19 小时Kansanshi is a copper gold mine located near Solwezi in the North Western Province producing copper concentrate, anode and cathode. It has been in operation since 2005. It has two open pits as...

Gold mining at home,Easy solution by gold stone channel

2023年3月7日Extracting gold from stone is a special pleasure, and if you are looking for it, you can follow my channel. Do not use excess acid as it will spoil the work....

Gold cyanidation Wikipedia

Gold cyanidation (also known as the cyanide process or the MacArthur-Forrest process) is a hydrometallurgical technique for extracting gold from low-grade ore by converting the gold to a water-soluble coordination complex. It is the most commonly used leaching process for gold extraction. [1]

Gold processing Mining and concentrating Britannica

Gold can be freed from these ores or concentrates by treating them with various oxidizing processes. The most common method is to roast gold-bearing minerals at temperatures of 450° to 750° C (840° to 1,380° F) to destroy the interfering sulfides.

Gold Mining: Why Clean Mining Is The Better Choice

In June 2022, Clean Mining signed a partnership with Gekko, a world technical leader in processing and low-energy mining solutions. Clean Mining solution in combination with Gekko’s world leading intensive leaching technologies (ILR) allows for gold processing to become more environmentally friendly, while achieving high recovery.

CIL Gold Mining Process, Equipment Mineral Processing

Carbon in Leach (CIL) process is widely used in the mining industry and in particular, it is an integral step of gold processing in gold extraction. Normally the CIL process can concentrate gold from 2.5–3.5 g/t in ore to 2000 to 6000 g/t on carbon. CIL gold process is suitable for the beneficiation of oxidized gold ore with low sulfur