Secondary Roll Crusher Used In Pakistan Out Put Size 10 To 50 Mm

Roll Crusher an overview ScienceDirect Topics

The secondary sizer would receive this coal and discharge at a nominal 125 mm, followed by a tertiary sizer/screen combination to generate a 50 mm topsize preparation plant

Crusher an overview ScienceDirect Topics

The secondary crusher is mainly used to reclaim the primary crusher product. The crushed material, which is around 15 cm in diameter obtained from the ore storage, is

进一步探索

5 Types Of Stone Crushers Application and MaintenanceTypes of Crushers Mineral ProcessingMetallurgy根据热度为您推荐•反馈

Roll Crusher| Double Roller Crusher |DOVE

2021年6月25日DOVE Roller Crushers are highly popular crushers in mining industry, with various advantages, such as high capacity, low horse power, low headroom, ability to handle wet ore, ability to handle sticky

secondary roll crusher used in pakistan out put size 10 to 50

2020年11月9日Double Roll Crusher, Capacity: 10 50 Tph ₹ 3.50 Lakh. Laxmi Engineers. Roll Crusher ₹ 1.50 Lakh. Output Size: 2 to 20mm Our organization

Roll Crushers McLanahan

Roll Crushers are designed to handle the primary, secondary and tertiary stage crushing of friable materials such as coal, salt, clay, bauxite, limestone and other minerals of similar

Stone Crushers: A Technical Review on Significant Part

2022年5月14日They are lighter in weight and smaller in size compared to primary crushers. The commonly used secondary crushers are cone, roll, and impact types.

Crushing Products Size and Shape -What to Expect

2016年2月26日Following the curve down to the 1.5″ line, we find that 43% of the primary crusher output may be expected to pass this screen opening; 57% will be retained,

Roll crushers SlideShare

2015年4月24日4. ROLL CRUSHER Roll crushers are used for producing additional reductions in the sizes of stone after the output of a quarry has been subjected to one or

Howto Size smooth Roll Crushers

Crushers Adam Zanker Smooth roll crushers are widely used as secondary crushers, operating most effectively when set for size re-ductions in a ratio between 3 or 4 to I. The

Jaw Crusher an overview ScienceDirect Topics

The relationship between the frequency of operation and capacity of the jaw crusher can be seen in Figure 4.5. This figure is plotted for values of LT = 0.228 m, W = 1.2 m, LMIN = 0.10 m, R = 10, G = 1 and the value of ν varied between 50 and 300 rpm. Sign in to download full-size image Figure 4.5.

Stone Crushers: A Technical Review on Significant Part

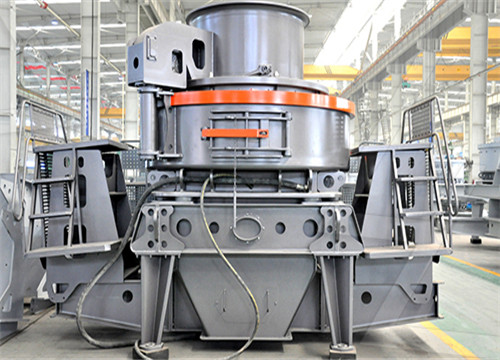

2022年5月14日They are lighter in weight and smaller in size compared to primary crushers. The commonly used secondary crushers are cone, roll, and impact types. The cone crusher is shown in Fig. 4. Are somewhat similar to gyratory type in construction. It has larger diameter crushing surface and very short spindle relative to its vertical cross

Selecting the Right Crushing Equipment Agg-Net

Secondary horizontal-shaft impact (HSI) crushers These crushers are characterized by a high 10:1 reduction ratio and by their suitability for generating a cubical product. They can also be used for a variety of applications. Secondary impact crushing is commonly used to improve product soundness and remove deleterious materials.

Select the crusher settings for a primary jaw crusher Chegg

Question: Select the crusher settings for a primary jaw crusher and a secondary roll crusher to produce 150 tons/h (136 t/h) of aggregate meeting the following specifications. Indi- cate the output in tons per hour (t/h) and in percentage for each of the specified size ranges. Screen Size in. (mm) 2% (6.4) 1 (25) (6) Percent Passing 100 50-60 15-30 Hint:

Roll crushers SlideShare

2015年4月24日4. ROLL CRUSHER Roll crushers are used for producing additional reductions in the sizes of stone after the output of a quarry has been subjected to one or more stages of prior crushing. Roll crushers have a theoretical MAXIMUM reduction ratio of 4:1. If a 2 inch particle is fed to the roll crusher the absolute smallest size one could

Problem 2: (20 points) Select the crusher settings Chegg

Transcribed image text: Problem 2: (20 points) Select the crusher settings for a primary jaw crusher and a secondary roll crusher to produce 150 tons per hour (136 th) of aggregate meeting the following specifications. Indicate the output in tons per hour (t/h) and in percentage for cach of the specified size ranges. Screen Size in. (mm) Percent Passing

Comminution University of Technology, Iraq

2. Output size (or finished size, final size): the smaller of the output size, the lower of the production capacity. 3. The humidity of the grinding materials. If the raw materials contain high percent water, the materials will easily adhere to the surface of the grinding mill and block the grinding speed. 4. The composition of the grinding

secondary jaw crusher used in pakistan out put size to mm

The new high-power crusher includes a constant feed opening, steep cavity and a wide range of effectiveused secondary jaw crusher out put size 10 to 50 mm price,25/04/2013 > Mining Equipment > used secondary jaw crusher out put size 10 to 50 mm price for pakistani rupees; Print. used secondary jaw crusher out put size 10 to

Roll Crushers ScienceDirect

2016年1月1日The roll size of a roll crusher was 30.5 cm × 90.1 cm. Gypsum rock (S.G. = 2.7, bulk density = 1.7 t/m 3) is to be crushed. Determine 1. the set in order to crush at the rate of 12 t/h and 10 rpm speed of the rolls, 2. the ratio between capacity and peripheral speed if the set was 2.5 cm, 3. the nip angle when the crusher feed size is 10 cm,

Double Roll Crushers McLanahan

Double Roll Crushers typically follow a primary or secondary crusher and are used for secondary and tertiary reduction of various minerals, such as ROM coal, clean coal, limestone, gypsum, trona, shale, bauxite, oil shale, coke, salt, lime, glass, kaolin, brick, shale and wet, sticky feeds. Applications Coal Crushing Mining Jump To:

Double Roll Crushers Moore Watson Ltd

Hypro-Crush ® Double Roll Crusher Series. The Hypro-Crush DRC series is a British engineered product designed for high speed production of fine minerals and can efficiently process both hard and soft materials. The main frame is of steel fabrication, accurately machined to accept the roller and drive shaft bearing housings and adjustment

What Type of Crusher Is Best for Primary Crushing?

2021年3月25日Roll Crushers are compression-type machines, so output gradation is controlled mainly through the gap setting between the rolls. A wider setting results in a coarser product. A wider setting also provides greater throughput. Single Roll Crushers feature a low-speed crushing roll that crushes material against a curved crushing plate.

P&Q University Lesson 7- CrushingSecondary Breaking

2019年9月2日In the quarry, crushing is handled in four potential stages: primary, secondary, tertiary and quaternary. The reduction of aggregate is spread over these stages to better control the product size and quality, while minimizing waste. The primary stage was once viewed merely as a means to further reduce stone following the blast or excavation

What is a Jaw Crusher? MEKA Crushing Equipment

Secondary Crushing This is the second stage of crushing. Feed size, which is around 150 to 300 mm, of the rock or ore from the primary crushing process is reduced to between 50 and 80 mm. Tertiary Crushing This is the third stage of crushing.

Stone Crushers: A Technical Review on Significant Part

2022年5月14日They are lighter in weight and smaller in size compared to primary crushers. The commonly used secondary crushers are cone, roll, and impact types. The cone crusher is shown in Fig. 4. Are somewhat similar to gyratory type in construction. It has larger diameter crushing surface and very short spindle relative to its vertical cross

Double Roll Crushers McLanahan

Double Roll Crushers typically follow a primary or secondary crusher and are used for secondary and tertiary reduction of various minerals, such as ROM coal, clean coal, limestone, gypsum, trona, shale, bauxite, oil shale, coke, salt, lime, glass, kaolin, brick, shale and wet, sticky feeds. Applications Coal Crushing Mining Jump To:

P&Q University Lesson 7- CrushingSecondary Breaking

2019年9月2日In the quarry, crushing is handled in four potential stages: primary, secondary, tertiary and quaternary. The reduction of aggregate is spread over these stages to better control the product size and quality, while minimizing waste. The primary stage was once viewed merely as a means to further reduce stone following the blast or excavation

Used Secondary Crushers for sale. Kpi-Jci equipmentmore

Used secondary crushers. CEDARAPIDS 5064 SECONDARY IMPACT (1989) 121057. USED. 1100 x 1000 mm The Crushers are 2 special containers that allows the refining. closed circuit Cedarapids 4026 Triple Roll Crusher with 2 decks, plus scalping screen. Top deck: 5’x14′, bottom deck: 5’x13′, scalping screen: 5’x42′. 50 HP motor

Select the crusher settings for a primary jaw crusher Chegg

Question: Select the crusher settings for a primary jaw crusher and a secondary roll crusher to produce 150 tons/h (136 t/h) of aggregate meeting the following specifications. Indi- cate the output in tons per hour (t/h) and in percentage for

Problem 2: (20 points) Select the crusher settings Chegg

Transcribed image text: Problem 2: (20 points) Select the crusher settings for a primary jaw crusher and a secondary roll crusher to produce 150 tons per hour (136 th) of aggregate meeting the following specifications. Indicate the output in tons per hour (t/h) and in percentage for cach of the specified size ranges. Screen Size in. (mm) Percent Passing

Long Time Using Coal Mining Crushing Equipment Smooth Double Roll

Long Time Using Coal Mining Crushing Equipment Smooth Double Roll Crusher Machine Price For Sand Making,Find Complete Details about Long Time Using Coal Mining Crushing Equipment Smooth Double Roll Crusher Machine Price For Sand Making,Coal Mining Machine,Mining Crushing Equipment Smooth Roll Crusher For Sale,Roll Mill

secondary jaw crusher used in pakistan out put size to mm

The new high-power crusher includes a constant feed opening, steep cavity and a wide range of effectiveused secondary jaw crusher out put size 10 to 50 mm price,25/04/2013 > Mining Equipment > used secondary jaw crusher out put size 10 to 50 mm price for pakistani rupees; Print. used secondary jaw crusher out put size 10 to

Comminution University of Technology, Iraq

2. Output size (or finished size, final size): the smaller of the output size, the lower of the production capacity. 3. The humidity of the grinding materials. If the raw materials contain high percent water, the materials will easily adhere to the surface of the grinding mill and block the grinding speed. 4. The composition of the grinding

Roll Crushers ScienceDirect

2016年1月1日Roll crusher sizes. Roll crushers are arbitrarily divided into light and heavy duty crushers. The diameters of the light duty crushers vary between 228 and 760 mm with face lengths between 250 and 460 mm. The spring pressure for light duty rolls varies between 1.1 and 5.6 kg/m.

What Type of Crusher Is Best for Primary Crushing?

2021年3月25日Roll Crushers are compression-type machines, so output gradation is controlled mainly through the gap setting between the rolls. A wider setting results in a coarser product. A wider setting also provides greater throughput. Single Roll Crushers feature a low-speed crushing roll that crushes material against a curved crushing plate.

Secondary crusher, Secondary crushing and screening plant All

stationary secondary tertiary. Capacity: 208 t/h. Opening height: 3,450, 4,100, 4,765 mm. Performance highlights Can be used in primairy, secondary, tertiary or quarternary crushing Designed to crush the toughest of rock and ore Feed size up to 185 mm (7”) C.S.S min. max. 6 38 mm (2/10”-1 5/10”), depending

Double Roll Crushers Moore Watson Ltd

Hypro-Crush ® Double Roll Crusher Series. The Hypro-Crush DRC series is a British engineered product designed for high speed production of fine minerals and can efficiently process both hard and soft materials. The main frame is of steel fabrication, accurately machined to accept the roller and drive shaft bearing housings and adjustment

Secondary Impact Crusher HSI

redefines secondary crushing technology. The new concept combines the knowledge gained from over 70 years of crusher design and manufacture, with the practical experience and operational needs of plant operators. The HSI series of secondary impactors have been designed for economic crushing and, depending on