Configuration Of Jaw Crusher Machine Dry And Wet Milling Machine For Dental5 Axis

Wet or Dry? The Need for Both Dental Milling Machines

2015年3月30日Roland DG’s DWX-50 5 Axis Dental (dry) Milling Machine and our new DWX-4W Wet Dental Mill offer a more flexible solution. Whatever your opinion is of the

进一步探索

wet and dry, dry milling 3d Dental CAD/CAM forumThe Differences between Dry Milling and Wet Milling DES根据热度为您推荐•反馈

Axsys Dental Solutions Versamill 5X200 5 Axis Dental Mill

Constructed utilizing the technology found in “full-frame” CNC industrial machines, the Versamill 5X-200 is designed to perform reliably with high precision for the long term.

Top 5 Milling Machines In The Dental Industry

The DWX-4W is a 4-axis wet milling machine that’s specifically designed for producing crowns, inlays, and bridges with glass ceramic and composite resin materials, and offer

4-Axis CNC Milling Machine for Production of Dental

2020年6月24日Abstract and Figures. This stone presents the development of a 4-axis CNC milling machine for making dental restorations. The machine was developed to

dry and wet milling machine for dental axis bhakti

Roland DGA Corporation, a leading provider of dental milling devices, announced today the simultaneous release of its new 4-axis wet dental mill, the DWX-4W, together with its

Wet Milling vs Dry Milling: The Differences, Advantages

2021年6月17日Wet milling, also known as wet grinding, is a process through which particles that are suspended in a liquid slurry are dispersed in that liquid by shearing or

5 Axis Dental Lab CAD CAM Milling Machine Unit tradekorea

NICE TECH KOREAas a professional dental CAD CAM system products MANUFACTURER, it is not only supplyingthe dental consumable materials like dental

dry and wet milling machine for dental5 axis

UNIMILL SDM5T 5. UNIMILL Dry Milling 5 Axis Machine Roland DWX-52D 5-Axis Dental Milling Machine Roland DWX-42W Dental Wet Milling Machine View More View More

dry and wet milling machine for dental5 a is

Top 5 Milling Machines In The Dental Industry . DWX-4W Wet Dental Mill Roland. The DWX-4W is a 4-axis wet milling machine that’s specifically designed for producing

S5 vhf Inc.

The 5-axis milling machine with blank changer for dry and wet machining. The S5 is a highly versatile dental milling machine. Large indication diversity due to a ± 30° rotation angle in the 5th axis, and up to 30 mm blanks; Optional wet-grinding module converts the S5 into a wet-processing machine; Tremendous stability. Processes all

Wet or Dry? The Need for Both Dental Milling Machines

2016年6月3日Roland DG’s DWX-50 5 Axis Dental (dry) Milling Machine and our new DWX-4W Wet Dental Mill offer a more flexible solution. Whatever your opinion is of the aesthetic or production values of glass ceramic vs. zirconia, the current restoration market is dictating a need for both options and labs should be responsive to this. Why Separate

Axsys Dental Solutions Versamill 5X200 5 Axis Dental Mill

Constructed utilizing the technology found in “full-frame” CNC industrial machines, the Versamill 5X-200 is designed to perform reliably with high precision for the long term. This purpose-built, open source 5-axis mill is designed to provide owners with maximum flexibility and versatility in a dental manufacturing system.

Blog Wet or Dry Milling Machines Which Is Right for You

2020年5月1日Dry Milling Dry Dental Mills are typically five axis machines that are capable of manufacturing larger and more complex Dental Prostheses, utilising materials in a 98mm disk form. These mills typically use various Carbide tools to mill restorations from Zirconia, Wax or PMMA materials.

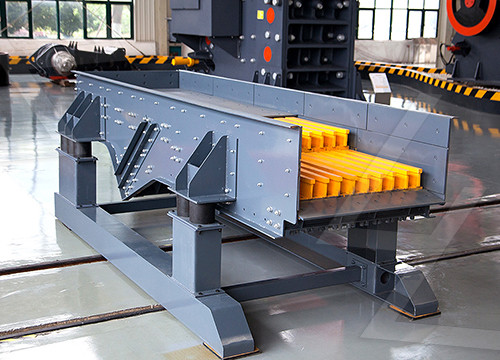

GrindingMilling Glen Mills, Inc.

Due to the low installation height (1 m), the BB 600 is ideally suited for continuous operation in automatic installations and sampling stations. Thanks to the compact design of the BB 600 it may replace a jaw crusher in existing installations. Small sample amounts with large particle sizes can be crushed batch-wise in the Jaw Crusher BB 600.

Crusher an overview ScienceDirect Topics

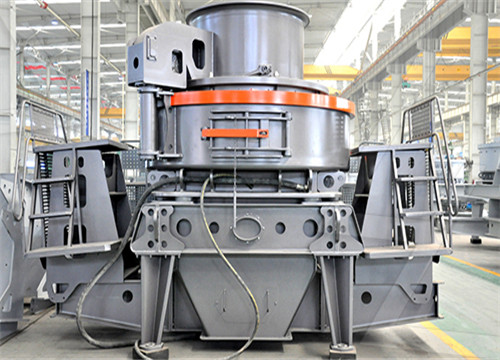

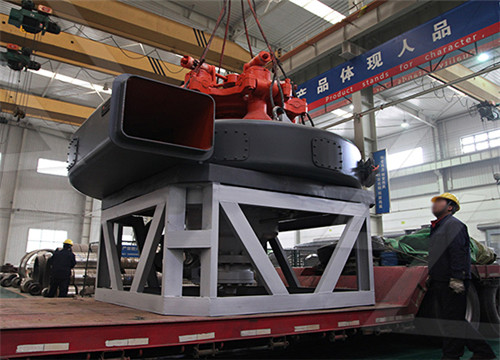

The common primary crushers are of jaw and gyratory types. The jaw crusher reduces the size of large rocks by dropping them into a “V”-shaped mouth at the top of the crusher chamber. This is created between one fixed rigid jaw and a pivoting swing jaw set at acute angles to each other.

Jaw crusher base composition and parts configuration

The jaw crusher, because its principle is more complex, there are a lot of jaw type crusher based operations, the following specific introduction: in the jaw crusher machine operation process, should always observe the rotor main bearing temperature, generally, normal temperature at sixty degrees Celsius, the highest temperature not exceeding

Ball mill, Grinding machine, Wet ball mill, Dry ball mill, Milling

2014年5月22日Ball mill is used to grinding ores or other materials after crusher, it is the mechanical equipment for getting finer particle products.

Dry And Wet Milling Machine For Dental5 Axis

2023年1月17日Simultaneous 5-axis milling, a- and b-axis with servo-motors wet and dry machining fully integrated extraction unit, pump and filter system easyclean for fast and simple change-over between dry and wet processing spindle with speed range from 6,000 rpm up to 100,000 rpm shaft with 4 mm diameter 8,4 ncm milling and grinding on one

dry and wet milling machine for dental5 a is

Top 5 Milling Machines In The Dental Industry . DWX-4W Wet Dental Mill Roland. The DWX-4W is a 4-axis wet milling machine that’s specifically designed for producing crowns, inlays, and bridges with glass ceramic and composite resin materials, and offer milling convenience through its multi-pin clamps, ball screw control, and automatic tool changer

Dry Professional Powder Grinder Crusher Mills, Cone Crusher, Jaw Crushers

Dry Powder Ball Milling, dry ball grinder liming Group with ball mill for sale with excellent price. Whole set dry ball mill production line. CHEF PRO CPG501 WET AND DRY GRINDER FOR 110volts

R5 vhf Inc.

The 5-axis milling machine for non-stop dry and wet machining. With the R5 a new high-end machine for the dental laboratory vhf has developed a highly automated milling and grinding machine that brings revolutionary approaches to the lab along with a ten-fold blank changer for wet and dry machining. In a minimal footprint, it combines

5 Axis Dental Lab CAD CAM Milling Machine Unit tradekorea

Milling, Drilling, Finishing machines. Not only for the local market but also, we are open for the importers who provide A/S for the end-users and support them locally as we care for each our client who enjoys using NiceTechKorea's Super and Mini Dental CAD/CAM 5 Axis Units during their service bringing high quality product to the modern life.

dry and wet milling machine for dental5 axis pp4.pl

Wet machining milling machine Know More. Find your wet machining milling machine easily amongst the 44 products from the leading brands Planmeca, Zirkonzahn, Schutz Dental,,on MedicalExpo, the medical equipment specialist for your professional purchas,Planmeca PlanMill® 50 is a 5-axis milling unit for both wet and dry milling of discs and

S5 vhf Inc.

The 5-axis milling machine with blank changer for dry and wet machining. The S5 is a highly versatile dental milling machine. Large indication diversity due to a ± 30° rotation angle in the 5th axis, and up to 30 mm blanks; Optional wet-grinding module converts the S5 into a wet-processing machine; Tremendous stability. Processes all

R5 vhf Inc.

The 5-axis milling machine for non-stop dry and wet machining. Highlights Features Download Technical Data Get advice now Highlights Features Download PDF Fact Sheets EN PDF Brochures EN Technical Data Do you have a question? Or would you like to receive more information? Phone +1 (631) 524-5252 Email info@vhf Contact form

Axsys Dental Solutions Versamill 5X200 5 Axis Dental Mill

5-Axis dental milling center capable of 5-Axis simultaneous machining including undercuts. Machine hard and soft materials including: titanium, stainless, CoCr, glass-ceramics, zirconia, PMMA and More. Ideal for the production of abutments, bar overdentures, bridges, copings, crowns and models.

Blog Wet or Dry Milling Machines Which Is Right for You

2020年5月1日Dry Dental Mills are typically five axis machines that are capable of manufacturing larger and more complex Dental Prostheses, utilising materials in a 98mm disk form. These mills typically use various Carbide tools to mill restorations from Zirconia, Wax or PMMA materials. The waste materials, known as swarf, are removed from the

Wet Milling vs Dry Milling: The Differences, Advantages

2021年6月17日Wet milling, also known as wet grinding, is a process through which particles that are suspended in a liquid slurry are dispersed in that liquid by shearing or crushing. Once the milling process is complete, these particles are ready for use or can be dried and separated for incorporation into additional products. Wet milling is more

GrindingMilling Glen Mills, Inc.

Due to the low installation height (1 m), the BB 600 is ideally suited for continuous operation in automatic installations and sampling stations. Thanks to the compact design of the BB 600 it may replace a jaw crusher in existing installations. Small sample amounts with large particle sizes can be crushed batch-wise in the Jaw Crusher BB 600.

Ball mill, Grinding machine, Wet ball mill, Dry ball mill, Milling

2014年5月22日0:00 / 3:57 Ball mill, Grinding machine, Wet ball mill, Dry ball mill, Milling machine, 47,551 views May 21, 2014 155 Dislike Share Save Eric Zhang 577 subscribers Ball mill is used to...

dry and wet milling machine for dental5 a is

Top 5 Milling Machines In The Dental Industry . DWX-4W Wet Dental Mill Roland. The DWX-4W is a 4-axis wet milling machine that’s specifically designed for producing crowns, inlays, and bridges with glass ceramic and composite resin materials, and offer milling convenience through its multi-pin clamps, ball screw control, and automatic tool changer

Jaw crusher base composition and parts configuration

The jaw crusher, because its principle is more complex, there are a lot of jaw type crusher based operations, the following specific introduction: in the jaw crusher machine operation process, should always observe the rotor main bearing temperature, generally, normal temperature at sixty degrees Celsius, the highest temperature not exceeding

Dry Professional Powder Grinder Crusher Mills, Cone Crusher, Jaw Crushers

Dry Powder Ball Milling, dry ball grinder liming Group with ball mill for sale with excellent price. Whole set dry ball mill production line. CHEF PRO CPG501 WET AND DRY GRINDER FOR 110volts

dry and wet milling machine for dental5 axis pp4.pl

Wet machining milling machine Know More. Find your wet machining milling machine easily amongst the 44 products from the leading brands Planmeca, Zirkonzahn, Schutz Dental,,on MedicalExpo, the medical equipment specialist for your professional purchas,Planmeca PlanMill® 50 is a 5-axis milling unit for both wet and dry milling of discs and

Primary Crusher an overview ScienceDirect Topics

Jaw crushers are mainly used as primary crushers to produce material that can be transported by belt conveyors to the next crushing stages. The crushing process takes place between a fixed jaw and a moving jaw. The moving jaw dies are mounted on a pitman that has a reciprocating motion. The jaw dies must be replaced regularly due to wear.

Jaw Crusher an overview ScienceDirect Topics

The ore is to be broken down in a jaw crusher to pass through a 11.5 cm screen. The undersize is scalped before feeding to the jaw crusher. Assuming the maximum feed rate is maintained at 30 t/h and the shapes of feed and product are the same and the crusher set is 10 cm, estimate the size of jaw crusher required and the production rate. Solution