Strong Construction Impact Crusher

Impact Crushers

Impact crushers (also known as impactors or horizontal shaft impactors) can be used in primary, secondary, or tertiary applications. They use inertia of the blowbars fitted to the

Crushers an overview ScienceDirect Topics

Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm. They are classified as jaw, gyratory, and cone crushers based on

进一步探索

4 Types of Stone Crushers' Maintenance and Efficient ImprDifferent types of crushers for distinctive needs Metso Out根据热度为您推荐•反馈

Types of Rock Crushers Quarry Crushing Equipment

Impact-style crushers include VSIs, as well as horizontal shaft impactors (HSIs), and are best used with less abrasive rock types, like limestone.

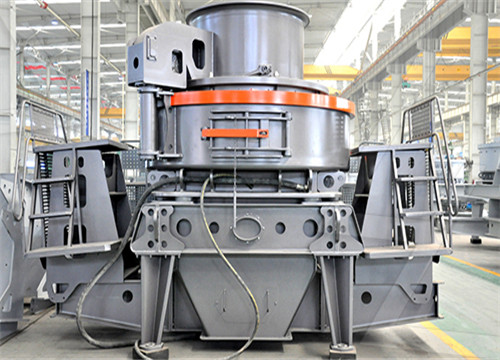

PFS Series Vortex Strong Impact Crusher ATAIRAC

DescriptionFeaturesWorking PrincipleTechnical Specification Specially designed three crushing chambers, which improves the production capacity of PFQ impact crusher, makes the feed size bigger and the product shape better.The optimally designed rotor provides powerful rotational inertia and strong impact force of hammer head, which improves the productivity and increases the crushing ratio.Specially designed anti-wear alloy C shape hammer keeps the shape of impact face in prod Specially designed three crushing chambers, which improves the production capacity of PFQ impact crusher, makes the feed size bigger and the product shape better.The optimally designed rotor provides powerful rotational inertia and strong impact force of hammer head, which improves the productivity and increases the crushing ratio.Specially designed anti-wear alloy C shape hammer keeps the shape of impact face in product life cycle. It ensures that the product shape and particle size distribution is very stable.Standard modular designed liner and tooth impact plate of PFQ impact crusher have common-ability and interchangeability, which improve the utilization ratio and prolong the service life of PFQ impa...展开选择时,新内容将添加到焦点当区域上方在atairac上查看更多信息

Types of Crushers: What You Need to Know Machinery Partner

Impact crushers have a very similar working principle except instead of the rotating parts hitting the material like a hammer, they instead throw the material against an impact

Impact Crusher Working Principle Mineral Processing

2015年6月23日Impact crushing crushing is the reduction of materials by rubbing; primarily a grinding method. Shear crushing is accomplished by breaking along or across lines of cleavage. It is possible, when required,

PFS Strong Impact Crusher

PFS strong Impact crusher can crush limestone, marble, granite, shale, coal, construction waste and other materials under medium hardness for medium and fine operations.This machine can directly crush the material

Bell ZA Mining and Construction Impact Crushers

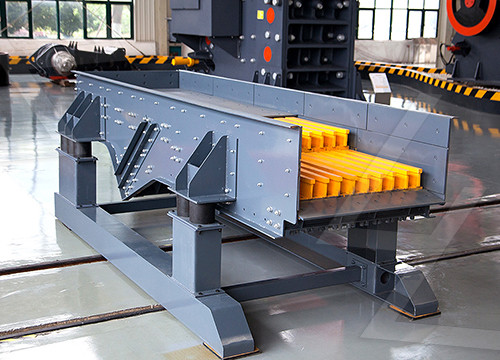

Key features: Fully hydraulic apron setting assist provides convenient and efficient adjustment of the chamber aprons. Heavy duty vibrating feeder (VGF) with integrated

Impact crushers high-quality impactors Metso Outotec

Impact crushers can be used in all different stages of size reduction from primary crushing to the last step of the crushing process. Contact our sales experts High performance

MR 110i EVO2 Mobile impact crushers mpl Wirtgen

The mobile impact crusher MOBIREX MR 110i EVO2 can be universally deployed and produces first-class final grain quality. With a crusher inlet of 1100 mm and numerous technical highlights, a formidable production rate can be achieved with the best cost effectiveness. Thanks to its compact design, the machine is easy to transport and can be

Crushing Equipment Superior Industries U.S.

benefits of impact crushing When utilized correctly, impact crushers are absolute rockstars! They produce some of the highest value, highest quality material in the aggregates industry SEE THE COMPARISON ? 2-Year /

Impact Crusher an overview ScienceDirect Topics

The impact crusher is commonly used for the crushing of limestone, coal, calcium carbide, quartz, dolomite, iron pyrites, gypsum, and chemical raw materials of medium hardness. Effect of process conditions on the production capacity of crushed materials is listed in Table 8.10. Table 8.10.

Impact Crushers: HorizontalVertical Shaft Ritchie List

2007 Screen Machine 4043T Impact Crusher Auburn, Washington 250 hrs $385,000 USD Listings by Seattle Tractor International, Inc. 2019 EVORTLE CT535 Impact Crusher Smyrna, Georgia 175 hrs $99,900 USD Listings by GrinderCrusherScreen 2015 QJ341 Impact Crusher Denver, Colorado $215,000 USD Listings by Proxy

Impact Crushers

Impact crushers (also known as impactors or horizontal shaft impactors) can be used in primary, secondary, or tertiary applications. They use inertia of the blowbars fitted to the rotor to fracture the material, resulting in a high reduction ratio. Impactors are often used as a cost effective alternative to jaw and cone combination plants as

Crushing Metso Outotec

From large primary jaws and gyratories to cone and impact crushers for tertiary and quaternary finishing, Metso Outotec equipment is manufactured to meet your material reduction requirements. The crushers are built to perform with the lowest cost per ton, featuring a unique combination of crusher cavity design, crushing forces, reliability and

PFS Series Vortex Strong Impact Crusher ATAIRAC

2021年5月27日Description PFQ Impact Crusher is a newly developed series impact crusher with high efficiency. It has smart structure and can be applied to primary crushing, secondary and fine crushing of a variety

PFS Strong Impact Crusher greatwallcrusher

PFS strong Impact crusher can crush limestone, marble, granite, shale, coal, construction waste and other materials under medium hardness for medium and fine operations.This machine can directly crush the material less than 600mm, get the building aggregate less than 40mm which combines the primary and secondary crushing into one.

Construction Working and Maintenance of Crushers for Crushing

Construction Working and Maintenance of Crushers for Crushing Bulk

5 Types of Concrete Crushers for Recycling Concrete Blocks

2023年2月28日Small/mini jaw crusher it is used for small size of concrete Weight:12t Capacity:1-30t/h Feeding size: 400×730 Power:37-45kw Small mobile jaw crusher Weight:39t Capacity: 10-80t/h Feeding size:500 Power:200kw Excavator concrete crusher Excavator concrete crusher can make it easy to process concrete mixed with mud and

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the...

6 Granite Crushers for Efficient Granite Crushing Fote Machinery

2023年2月28日The impact crusher has a large feeding port, a deep crushing cavity and a large crushing ratio, which can effectively complete the fine crushing of granite. The gap between the impact plate and the hammer can be easily adjusted, which can effectively control the granularity of the finished granite.

Mobile Stone Crusher Plant Mobile CrushingScreening Plant

Impact crusher can treat material with a edge length of less than 100-500mm. The maximum pressure resistance can reach 350 MPA. It has advantages of large crushing ratio, cubic particles after crushing. Circular vibrating screen is

Mobile crushers and screens — SRP

Our high-capacity mobile scalpers are flexible and hard-wearing for virtually any application, including construction waste, landfill mining, quarry overburden, scalping before a crusher or screening aggregates after a crusher. Every product is backed by unrivaled aftermarket support to help keep your equipment running at optimum levels

Impact Crushers

Impact crushers (also known as impactors or horizontal shaft impactors) can be used in primary, secondary, or tertiary applications. They use inertia of the blowbars fitted to the rotor to fracture the material, resulting in a high reduction ratio. Impactors are often used as a cost effective alternative to jaw and cone combination plants as

Impact Crushers: HorizontalVertical Shaft Ritchie List

2007 Screen Machine 4043T Impact Crusher Auburn, Washington 250 hrs $385,000 USD Listings by Seattle Tractor International, Inc. 2019 EVORTLE CT535 Impact Crusher Smyrna, Georgia 175 hrs $99,900 USD Listings by GrinderCrusherScreen 2015 QJ341 Impact Crusher Denver, Colorado $215,000 USD Listings by Proxy

Crushing Metso Outotec

The high-capacity, reliable and energy efficient crushing solutions deliver superior performance and maximized throughput also for the most demanding mining applications. Contact our sales experts Increase capacity 5 more days of annual uptime and a significant increase in capacity. Better throughput and faster maintenance

PFS Series Vortex Strong Impact Crusher ATAIRAC

2021年5月27日Description PFQ Impact Crusher is a newly developed series impact crusher with high efficiency. It has smart structure and can be applied to primary crushing, secondary and fine crushing of a variety of materials with compression strength less than 250Mpa. PFQ impact crusher can be widely used for sand and aggregate processing in

Impact Crushers For Sale Ritchie Bros. Auctioneers

An impact crusher is a stone pulverizer machine that strikes materials, such as cement, rock, minerals, etc., to pulverize it and to create a finished product. Buying an impact crusher is a cost-efficient alternative to impact crusher rental or buying new.

ISP Strong Fine Impact Crusher Luoyang Dahua

It is widely used to process sand and aggregate in the field of construction for water and electricity, highway, city construction. Features. 1. There are two different adjustable crushing cavities of ISP impact crusher, which increases the efficiency. The main equipment: jaw crusher, strong impact crusher, PLS sand making machine, heavy

PFS Strong Impact Crusher greatwallcrusher

PFS strong Impact crusher can crush limestone, marble, granite, shale, coal, construction waste and other materials under medium hardness for medium and fine operations.This machine can directly crush the material less than 600mm, get the building aggregate less than 40mm which combines the primary and secondary crushing into one.

Construction Working and Maintenance of Crushers for Crushing

Construction Working and Maintenance of Crushers for Crushing Bulk

Manufacturing Construction Retains Strong Outlook, Report Says

7 小时Construction averaged 390,500 open, unfilled jobs per month in 2022. In December, 5% of construction jobs were unfilled. “As a result, construction wages are rising at a much faster rate than

Mobile crushers and screens — SRP

Our high-capacity mobile scalpers are flexible and hard-wearing for virtually any application, including construction waste, landfill mining, quarry overburden, scalping before a crusher or screening aggregates after a crusher. Every product is backed by unrivaled aftermarket support to help keep your equipment running at optimum levels

The difference between stone hammer crusher and impact crusher

2023年3月10日Impact crushers are typically easier to maintain, as they have fewer moving parts and are designed for easier access to key components. Application:Stone hammer crushers are typically used for

(PDF) SIZE REDUCTION BY CRUSHING METHODS ResearchGate

2017年3月4日The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the...

Quarry Crawler Type Portable Stone Jaw Crusher Machine

Features of Our Crawler Mobile Crusher. 1. Strong power of diesel engines, Low fuel consumption and noise, powerful horsepower, energy saving and high yield. 2. Convenient and fast, Outlet size can be controlled by hydraulic, with advantages of convenient and fast. 3. Intelligent operation With wireless remote control, self-tracked walking.. 4. All-steel