Problems On A Crusher Plant

Crushing Plant an overview ScienceDirect Topics

Mobile crushing plants are not suited to large long-life projects, heavy rainfall climates, or arctic climates. The design considerations, operability, and maintainability require careful

进一步探索

Crushing Plant FlowsheetDesign-Layout Mineral Proc4-types-of-crushing-plant根据热度为您推荐•反馈

Environmental GUIDELINE ON STONE CRUSHING plant

A stone crushing plant is primarily involved in the manufacture of aggregates of various sizes (coarse aggregates, crusher run, rock sand and other fine aggregates) from basalt

Tips to maximize crushing efficiency PitQuarry

2019年5月13日The closed-side setting of a jaw crusher helps determine the nip angle within a chamber, typically 19 to 23 degrees. Too large of an angle causes boiling in the

HSE Quarries Safe operation and use of mobile jaw

In some cases, however, an amount of removal by hand will be involved and when this occurs the crusher and associated plant must be stopped and isolated Manual removal

ENVIRONMENTAL ISSUES IN STONE CRUSHERS The

2012年1月8日ENVIRONMENTAL PROBLEMS IN STONE CRUSHERS 3.1 Sources of Emissions All quarrying and stone processing operations including surface mining, crushing, screening, material handling and

Crushing Plant FlowsheetDesign-Layout Mineral

2016年3月10日Operating the crusher at too narrow a setting decreases capacity and creates high wear. Too wide an opening, in proportion to topsize feed, will prevent crushing in the upper zone and will develop

15 Common Indoor Plant Problems: Treatment,

2021年6月11日12. Brown Leaves. Just as overwatering can harm your plant, keeping it too dry can also lead to various problems. Signs that you’re not watering your plant enough include: wilting, drooping, or

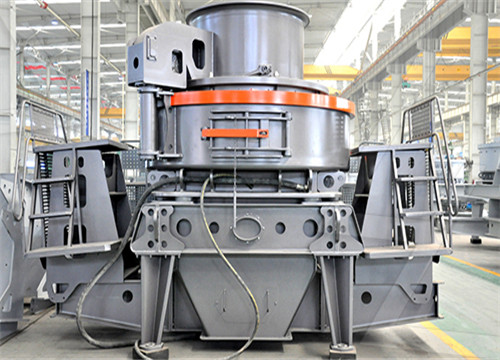

4 Types of Stone Crushers' Maintenance and Efficient

2023年2月15日Common problems you would face when operating a jaw crusher 1 Premature bearing failures. That's because you haven't make a regular cleaning in the oil chamber which is full of dust and fines. If

Tips for Crusher Maintenance Thomasnet

2018年11月28日Follow crusher backing maintenance schedule carefully to avoid undue damage to equipment. Every 40 hours, check for leaks and inspect Y strainers. Every month, inspect safety devices and perform an

Crushing Plant Performance Optimization Agg-Net

In a crushing plant, the normal procedure for studying and improving the process is by means of measurements, rules of thumb and visual observations. However, these tools and methods are inadequate for more advanced analyses of the complex processes that characterize many crushing plants.

HSE Quarries Safe operation and use of mobile jaw crushers

Accidental start up of feeder, crusher or adjacent plant Being struck by material from the feeder, chute or projected material The movement of any material present inside the crusher Slipping...

Frequent problems in crushing, screening, grinding and

2022年5月19日Frequent problems in crushing, screening, grinding and beneficiation process of mining plant. At present, the commonly used mineral processing equipment in mineral processing plants include crushing equipment, grinding equipment, screening equipment, magnetic separation equipment, and flotation equipment. The following is an

Gyratory VS Jaw Crushers: Advantages

2016年2月28日The jaw crusher does not lose any of its “new-condition” throw when the babbitt wears in the main, or in the pitman, bearings. The jaw crusher will handle sticky,’or dirty feed better than the gyratory,

How to solve problems in stone crusher plant baichy

stone crusher plant, quarry plant, sandstone crusher, granite crusher machines, stone crusher wearing parts, problems in stone crusher plant. Home About us. Products. Mobile Crusher Plant. How to solve problems in stone crusher plant . 2020-03-26 15:22:31. Baichy. Consulting.

Aggregate Screen Problems and Solutions JXSC

The reasons for the aggregate screen can’t startup 1. Power First, we see if there’s a problem in the power or the motor. If it is a motor failure, it replaces new motor parts is ok. The vibrating screen working assembly

15 Common Indoor Plant Problems: Treatment,

2021年6月11日12. Brown Leaves. Just as overwatering can harm your plant, keeping it too dry can also lead to various problems. Signs that you’re not watering your plant enough include: wilting, drooping, or

An investigation into respiratory health problems

2018年3月5日It also shows that coughing was the most common problem among the respondents. The majority of respondents suffered from obstructive types of respiratory problems.,Findings of the study reveals

水泥厂破碎机润滑改良,轴承温度下降3-4℃,优润(U.LUBE)高负载轴承脂 Cement plant crusher

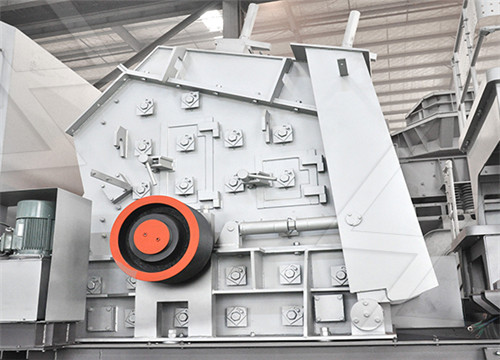

A cement plant double rotor crusher currently has a high bearing temperature problem. After U.LUBE team's on-site research, the working condition of the crusher in this cement plant is harsh with low bearing speed/heavy load, accompanied by impact load and dust. The use of previous lubrication grease has poor lubrication performance, which can

More Than a Nuisance ConstructionDemolition Recycling

The symptoms of the disease include shortness of breath, possible fever, fatigue, loss of appetite, chest pain, a “dry, nonproductive cough,” and ultimately, “respiratory failure, which may eventually lead to death.”

Types of Rock Crushers Quarry Crushing Equipment Kemper

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2. Secondary Crushing.

Crushing Plant Performance Optimization Agg-Net

In a crushing plant, the normal procedure for studying and improving the process is by means of measurements, rules of thumb and visual observations. However, these tools and methods are inadequate for more advanced analyses of the complex processes that characterize many crushing plants.

HSE Quarries Safe operation and use of mobile jaw crushers

Accidental start up of feeder, crusher or adjacent plant Being struck by material from the feeder, chute or projected material The movement of any material present inside the crusher Slipping...

(PDF) Environmental health assessment of stone crushers

2011年3月23日Present investigations show that exposure to dust can cause serious respiratory (45.11%), skin (43.33%), hearing (21.53%), eye (17.8%), dyspnea (14.66%) like health problems. Present study...

Frequent problems in crushing, screening, grinding and

2022年5月19日If the feeding granularity is inappropriate, it will not only affect the crushing effect, but also cause serious wear of the tooth plates, brackets and gaskets. When the feeding granularity is too large, the crusher with sliding structure will be more seriously damaged. (4) Insufficient lubrication of equipment

Problems That Need To Be Paid Attention To When Storing The Crusher

At present, we need to pay attention to a lot of problems when using crusher machine. We should also pay attention to a lot of problems during storage, but we always pay little attention to it. 10 Advantages Of Mobile Crushing Plant Compared With Ordinary Crusher. Analysis On Advantages Of Mobile Crushing Plant.

Aggregate Screen Problems and Solutions JXSC

The reasons for the aggregate screen can’t startup 1. Power First, we see if there’s a problem in the power or the motor. If it is a motor failure, it replaces new motor parts is ok. The vibrating screen working assembly

An investigation into respiratory health problems

2018年3月5日Findings of the study reveals that chronic exposure to dust at stone crushing plants increases the risk of respiratory problems and the impaired lung function of workers. It also reveals that there is a

How to solve problems in stone crusher plant baichy

stone crusher plant, quarry plant, sandstone crusher, granite crusher machines, stone crusher wearing parts, problems in stone crusher plant. Home About us. Products. Mobile Crusher Plant. How to solve problems in stone crusher plant . 2020-03-26 15:22:31. Baichy. Consulting.

15 Common Indoor Plant Problems: Treatment,

2021年6月11日12. Brown Leaves. Just as overwatering can harm your plant, keeping it too dry can also lead to various problems. Signs that you’re not watering your plant enough include: wilting, drooping, or

水泥厂破碎机润滑改良,轴承温度下降3-4℃,优润(U.LUBE)高负载轴承脂 Cement plant crusher

A cement plant double rotor crusher currently has a high bearing temperature problem. After U.LUBE team's on-site research, the working condition of the crusher in this cement plant is harsh with low bearing speed/heavy load, accompanied by impact load and dust. The use of previous lubrication grease has poor lubrication performance, which can

Types of Rock Crushers Quarry Crushing Equipment Kemper

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2. Secondary Crushing.

P&Q University Lesson 7: CrushingSecondary Breaking

2019年9月2日A lined, heavy-duty vibrating feeder below the crusher can eliminate belt wear from rebar or dowel or tie bar damage. If present beneath the crusher, this deflector plate can keep tramp metal from degrading the conveyor belt. That way, the feeder below the crusher not the belt absorbs impact of rebar dropping through the crusher.

Tips for Crusher Maintenance Thomasnet

2018年11月28日Check balance cylinder (s) every 30 days of operation. Keep oil and lubrication clean. Check daily, every 8 hours. Follow crusher backing maintenance schedule carefully to avoid undue damage to equipment. Every 40 hours, check for leaks and inspect Y strainers. Every month, inspect safety devices and perform an oil analysis.