Simon Flotation Cell Zinc Ore Mining Feeder Mining

Silver Lead Zinc Ore Processing Method using Flotation

2016年4月20日Silver Lead Zinc Ore Processing Method using Flotation Sulphide ore of lead and zinc containing considerable silver was

Quality Mining Flotation CellMining Mixer factory from China

China Mining Flotation CellMining Mixer Manufacturer A wide selection of high quality products for you High Recovery Rate Mining Flotation Cell 1370KG Low Energy

Flotation MachinesFlotation Cells 911Metallurgist

ConditioningFlotationFlotation MachinesThe selection of flotation cell size and configuration can have a substantial influence upon installed cost and can contribute to operational efficiency. Two possible flotation configurations for a 500 metric ton per day installation are presented in Figure 5. The computational basis assumes 30 percent solids in rougher flotation, 20 percent solids...

Flotation Cells Prominer (Shanghai) Mining

Flotation Cells Prominer can provide SF series self-priming flotation machine and XCF/KYF series pneumatic flotation cell which are mainly used. for the recovery and upgrading of sulfide ores such as cooper ore,

Lead Zinc Mining SolutionEquipment Mineral Processing

Generally, lead zinc flotation processing plant main process divided into three stages: crushing and screening grinding flotation separation- concentate and dewatering.

Reliable equipment for iron ore mines

For the large volumes of iron ore you produce every day, you need proven and reliable equipment to sustain or increase your production level and avoid unplanned stops.

How to Select the Froth Flotation Method Used in the

2020年2月26日Here are 5 commonly used froth flotation methods for Pb-Zn sulfide ore extraction: Priority froth flotation method. Mixed froth flotation method. Iso-flotation method. Differential branching flotation

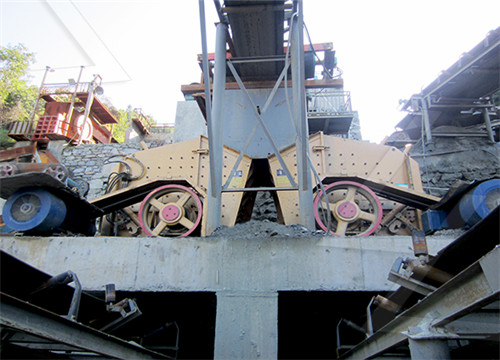

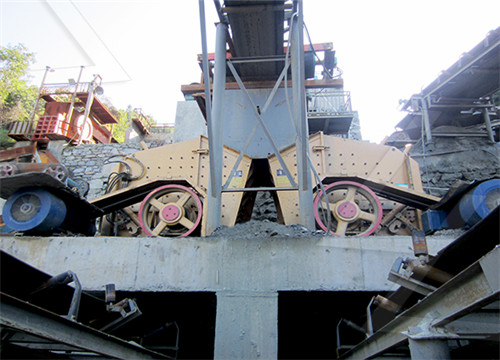

Plunger Ore Feeder Pendulum Feeder JXSC Machine

Pendulum feeder/ plunger ore feeder is a kind of mining auxiliary equipment of mineral transport machinery, it is suitable for short moment distance, according to a certain amount of small and large proportion of

Surface chemistry investigation of froth flotation products of lead

2021年1月1日As shown in Fig. 1, before flotation, 800 g lead-zinc sulfide ore, 500 g water, depressant (8000 g/t lime) and collectors (50 g/t sodium diethyldithiocarbamate and 50 g/t sodium butyl xanthate) were added to a ball mill and ground for 5.5 min.Thereafter, the pulp was transferred to an XFD-63 flotation cell (self-aeration) whose volume for

The critical importance of pulp concentration on the flotation

2016年4月1日The lead–zinc ore was supplied by Nanjing Yinmao Lead-zinc Mining Co., Ltd., China. The ore is of low lead grade (approximately 1.3%). The results of the chemical analysis are shown in Table 1.A quantitative mineralogy determination using X-ray powder diffraction (XRD) and mineral liberation analyzer (MLA) were done by the analytical

Copper Lead Zinc Mining Mineral ProcessingMetallurgy

2016年11月21日A 10-cell No. 18 Special “Sub-A” Flotation Machine is used for zinc flotation and is divided into 6 cells for roughing, 2 cells for cleaning, and 2 cells for recleaning, the final tailing is then sampled and sent to the tailing dam by gravity. Mill nearing completion.

North Ltd Zinc, Lead and Silver Mine Mining Technology

2000年3月26日Production. In 2009 production of zinc reached 51,370t while lead and silver production was 25,894t and 1,356,003oz respectively. The mine concentrator treated 720,679t of ore to yield 759,395t of output. The average zinc grade was 7.3% and the lead grade 4%. The cash cost of production was approximately $0.26/lb, net of byproducts.

Lead-Zinc ores Danafloat

The established lead-zinc ore flotation processing scheme is to add zinc sulphate (ZnSO4) to the grind to control metal ion activation (sphalerite depression). Often metabisulphide or other sulphidation chemicals are added with the zinc sulphate for

Flotation MachinesFlotation Cells 911Metallurgist

Flotation. The selection of flotation cell size and configuration can have a substantial influence upon installed cost and can contribute to operational efficiency. Two possible flotation configurations for a 500 metric ton per day installation are presented in Figure 5. The computational basis assumes 30 percent solids in rougher flotation, 20

Quality Mining Flotation CellMining Mixer factory from China

Y&X Beijing Technology Co.,Ltd. was established in 2014.As a member of a family mining group, the mission from the beginning was to expand overseas markets and provide one-stop professional services for overseas mining companies. The mining group owns various type mines including iron, copper, molybdenum, lead-zinc, phosphorus, gold, etc,and

SF Flotation Cell, Floatation Method, Flotation Machine, Flotation Cell

SF flotation cell could improve concentrate grade 4-6%, recovery rate 8% and capacity 12%, and it is widely used in flotation process as flotation machine. marketing@ytxinhai 0086

Copper Flotation, Extraction of Copper, Copper Xinhai Mining

Zinc flotation adopted a roughing, three scavenging, four cleaning process, roughing and scavenging adopted KYF flotation cell, and cleaning selected SF flotation cell BF flotation cell was used in copper lead separation process. The dewatering of copper, lead and zinc concentrates used Xinhai efficient deep cone thickener + ceramic filter.

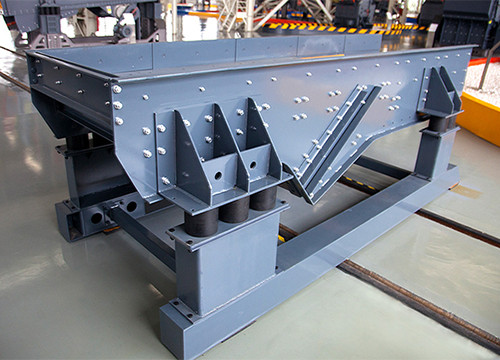

Plunger Ore Feeder Pendulum Feeder JXSC Machine

Pendulum feeder/ plunger ore feeder is a kind of mining auxiliary equipment of mineral transport machinery, it is suitable for short moment distance, according to a certain amount of small and large proportion of material transport, its grain size is less than 35 ~ 100 mm; not suitable for viscous materials. The vibratory feeder is suitable for

Flotation process of lead-zinc oxide ore Prominer (Shanghai) Mining

2020年9月9日Among the zinc oxide minerals, the more valuable is zincite, in addition to zinc ore, willemite and so on. In the flotation of zinc oxide minerals, the flotation operation can be carried out by using xanthate or normal temperature cation collection after heating and vulcanization.

The critical importance of pulp concentration on the flotation of

2015年12月11日The Qixia orebody is a complex lead–zinc sulfide system with pyrite gangue and minor amounts of copper. In order to improve the flotation results, laboratory scale flotation testing of ore

How to Select the Froth Flotation Method Used in the Extraction

2020年2月26日Here are 5 commonly used froth flotation methods for Pb-Zn sulfide ore extraction: Priority froth flotation method. Mixed froth flotation method. Iso-flotation method. Differential branching flotation method. Potential-controlled flotation method. The Pb-Zn sulfide ore is often associated with a variety of valuable components, such as lead

Lithium Processing Plant JXSC Machine

2022年7月5日Lithium Processing Plant. Release time:05 July 2022. Lithium is an element valuable for the production of glass, aluminum products, and batteries. With the development of technology, electronic equipment, and new energy industries, the demand for lithium ore has increased rapidly. Therefore, lithium ore is known as the “energy

Surface chemistry investigation of froth flotation products of lead

2021年1月1日Flotation tests As shown in Fig. 1, before flotation, 800 g lead-zinc sulfide ore, 500 g water, depressant (8000 g/t lime) and collectors (50 g/t sodium diethyldithiocarbamate and 50 g/t sodium butyl xanthate) were added to a ball mill and ground for 5.5 min.

The critical importance of pulp concentration on the flotation

2016年4月1日The lead–zinc ore was supplied by Nanjing Yinmao Lead-zinc Mining Co., Ltd., China. The ore is of low lead grade (approximately 1.3%). The results of the chemical analysis are shown in Table 1.A quantitative mineralogy determination using X-ray powder diffraction (XRD) and mineral liberation analyzer (MLA) were done by the analytical

North Ltd Zinc, Lead and Silver Mine Mining Technology

2000年3月26日Production. In 2009 production of zinc reached 51,370t while lead and silver production was 25,894t and 1,356,003oz respectively. The mine concentrator treated 720,679t of ore to yield 759,395t of output. The average zinc grade was 7.3% and the lead grade 4%. The cash cost of production was approximately $0.26/lb, net of byproducts.

The critical importance of pulp concentration on the flotation of

2015年12月11日The Qixia orebody is a complex lead–zinc sulfide system with pyrite gangue and minor amounts of copper. In order to improve the flotation results, laboratory scale flotation testing of ore

Flotation MachinesFlotation Cells 911Metallurgist

Flotation. The selection of flotation cell size and configuration can have a substantial influence upon installed cost and can contribute to operational efficiency. Two possible flotation configurations for a 500 metric ton per day installation are presented in Figure 5. The computational basis assumes 30 percent solids in rougher flotation, 20

Quality Mining Flotation CellMining Mixer factory from China

China Mining Flotation CellMining Mixer Manufacturer A wide selection of high quality products for you High Recovery Rate Mining Flotation Cell 1370KG Low Energy Consumption Get Best Price Energy Saving Mining Mixer Agent Agitation Tank For Gold Dressing Plant Get Best Price Hydraulic Central Transmission Mining Thickener Gold

SF Flotation Cell, Floatation Method, Flotation Machine, Flotation Cell

SF flotation cell could improve concentrate grade 4-6%, recovery rate 8% and capacity 12%, and it is widely used in flotation process as flotation machine. marketing@ytxinhai 0086

How to Select the Froth Flotation Method Used in the Extraction

2020年2月26日Here are 5 commonly used froth flotation methods for Pb-Zn sulfide ore extraction: Priority froth flotation method. Mixed froth flotation method. Iso-flotation method. Differential branching flotation method. Potential-controlled flotation method. The Pb-Zn sulfide ore is often associated with a variety of valuable components, such as lead

Plunger Ore Feeder Pendulum Feeder JXSC Machine

Pendulum feeder/ plunger ore feeder is a kind of mining auxiliary equipment of mineral transport machinery, it is suitable for short moment distance, according to a certain amount of small and large proportion of material transport, its grain size is less than 35 ~ 100 mm; not suitable for viscous materials. The vibratory feeder is suitable for

Flotation process of lead-zinc oxide ore Prominer (Shanghai) Mining

2020年9月9日Among the zinc oxide minerals, the more valuable is zincite, in addition to zinc ore, willemite and so on. In the flotation of zinc oxide minerals, the flotation operation can be carried out by using xanthate or normal temperature cation collection after heating and vulcanization.

Lithium Processing Plant JXSC Machine

2022年7月5日Spodumene processing can be used for positive flotation or reverse flotation. The positive flotation process is the process of preferential flotation of spodumene. The method is to add sodium hydroxide to the slurry at the beginning to stir and scrub to remove the pollutants on the surface.

Chute feeder Yantai Jinpeng Mining equipment, ore dressing

The chute feeder (also called slot type) can be installed on the ground ,also can be lifting unloading port in the ore bin. It is through the base of reciprocating motion, the massive material storage silos by delivery to the receiving device, not suitable for conveying powder material. Feeding capacity : 10~90t/h . Max particle : 50-350mm

Froth Flotation Process Used in the Lead Zinc Sulfide Ore

2020年2月20日The differential branching flotation process used in lead-zinc sulfide ore is to quickly float the lead zinc ore which can be floated fast and easily, and then float the lead zinc ore which is floated slowly and difficultly. This froth flotation process is applicable to lead and zinc sulfide minerals with different flotation behaviors due to