The Necessity Of Tailings Flotation Machine

Flotation an overview ScienceDirect Topics

Flotation is widely used to separate valuable minerals from the rock and fine coal particles from clay, silt, shale and other ash-producing matter. It is usually preceded by crushing

Minerals Free Full-Text The Challenges and Prospects of MDPI

2022年5月6日The presence of fine particles in flotation circuits is largely the result of excessive grinding, performed to achieve a higher degree of mineral liberation. As

Renewed focus on the importance of flotation Metso

2019年1月21日In general, one type of flotation equipment is not appropriate for a complete concentrator and it is necessary to implement

Environmental desulfurization of mine tailings using froth flotation

2022年9月1日This research examined the the desulfurization of tailings from the Amaruq mine at a laboratory scale using froth flotation. Optimization of the flotation process

Efficiency Assessment of Allflot Pneumatic Flotation

2021年7月20日The results of qualitative and quantitative calculations of the flotation process as applied to the slime fraction of old tailings are given. Conclusions about the

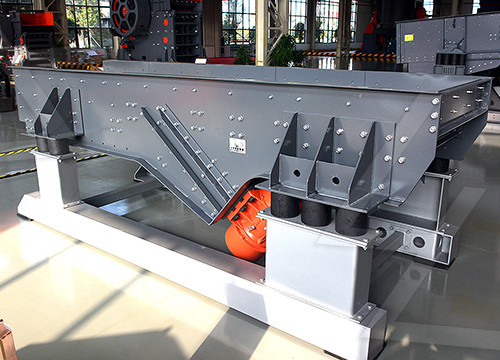

The necessity of tailings flotation machine deepconenet

2015年3月17日The necessity of tailings flotation machine. Tailings refers to the waste slag in mining, smelting enterprises discharge, mostly mud efflux form, over the formation

(PDF) Examination of the possibility of obtaining pyrite

2022年1月1日Russian machines installed in 1976 are still in use for zinc mineral flotation. After the reconstruction, the old line for flot ation of lead minerals remained

CIL Tailings Gold Flotation MetallurgistMineral

2017年11月27日The recent addition of a pressure oxidation circuit at Mercur provided a potentially viable treatment option that enhanced the prospect of flotation as a means of recovering gold which is lost to the

Flotation Mineral ProcessingMetallurgy

2016年1月11日This cleaner-cell is a machine of the same construction as the rougher; in operation, however, it is usually run with a lower air-pressure; the tailing from the cleaner is pumped by D-2 back to the original feed,

FOH Institute of Physics

2021年2月10日with the tailings flotation classification being drained. A schematic diagram of flotation classification enrichment in a closed grinding cycle is presented, and the results of calculating final flotation classification parameters for sulphide copper ore dressing are presented. Unlike SkimAir flotation machines, flotation classifiers can

IMPROVED FLOTATION OF FINE PGM TAILINGS WITH A

complement rather than replace flotation size bubbles (Nesset et al., 2006). Research has shown that the ageing of micro (pico) bubbles as well as flotation sized bubbles was detrimental to particle-bubble attachment and that future the optimum flotation conditions would be obtained under conditions in which the two are co-generated.

Grade prediction of zinc tailings using an encoder-decoder

2021年10月1日In this study, the grade prediction of zinc tailings from the first rougher is our research task (shown as purple dotted line in Fig. 1), and it involves 6 flotation cells, i.e., three rougher cells and three scavenger cells, as shown in Fig. 1. All the 6 flotation cells are self-aspirating mechanical stirring flotation machines.

Minerals Free Full-Text The Challenges and Prospects of MDPI

2022年5月6日The presence of fine particles in flotation circuits is largely the result of excessive grinding, performed to achieve a higher degree of mineral liberation. As discussed, the tailings mostly contain the finest and coarsest size fractions. A few review limestonehave addressed fine and coarse particle flotation [ 25, 26, 27, 28, 29 ].

Renewed focus on the importance of flotation

2019年1月21日In general, one type of flotation equipment is not appropriate for a complete concentrator and it is necessary to implement specific machines to meet specific needs. Efficiency, advanced process

Mechanical Properties and Hydration Mechanism of Coal Flotation

2023年3月10日Large-scale application of filled coal mining technology has long been limited by conditions such as the cost of filling. Compared to traditional filling materials, coal flotation tailing filling materials (CFTFM) offers advantages such as low cost and excellent performance. The Box–Behnken response surface method was used to investigate the

Extraction of rare earth elements from upgraded phosphate

In this work, phosphate flotation tailings were upgraded by gravity separation and froth flotation. Gravity separation was conducted using a laboratory shaking table, while flotation was conducted in a Denver D-12 flotation cell. The concentrated tailings were then leached by nitric acid followed by REE extraction with solvent and ion-exchange

The necessity of tailings flotation machine deepconenet

2015年3月17日The necessity of tailings flotation machine. Tailings refers to the waste slag in mining, smelting enterprises discharge, mostly mud efflux form, over the formation of the tailings. Because the library contained a large amount of hard exudates Whey, in the absence of tailings seepage dry, has a price component re-election, backfilling mined

Vale begins Gelado tailings re-use project commissioning with

2023年3月3日In addition to providing a sustainable destination for the tailings, the project will use 100% electric dredges to extract the material, avoiding CO2 emissions. The initial production capacity will be 5 Mt/y and the investment is $485 million.

Use of Ammonia Salts in Selective Copper Extraction from Tailings

2020年6月3日Tailings (flotation waste) that is formed during copper production may be considered in the class of valuable wastes due to the amount of copper it contains. Owing to the decreasing grade values in copper ores, utilization of wastes such as tailings that carry certain amounts of copper as secondary sources has become a necessity in both the

Challenges and opportunities in the recovery/rejection of trace

DOI: 10.1016/J.MINENG.2015.04.008 Corpus ID: ; Challenges and opportunities in the recovery/rejection of trace elements in copper flotation-a review @article{Agorhom2015ChallengesAO, title={Challenges and opportunities in the recovery/rejection of trace elements in copper flotation-a review}, author={Eric

Tailings solutions: How to filter down the options

Potential water recovery potentials for copper flotation tailings are shown in the below table. In Chile, current estimates for the cost of desalinated water pumped to the mine are as high as $5 per cubic meter or higher. Machines are supplied in widths of up to 4 meters, with capacities of between 5 and 15 tons per hour (tph) of dry solids

Operating practices in the beneficiation of major porphyry copper

The importance of the application of new technology for improvement in plant metallurgical results is highlighted. S. Bulatovic Flotation Behaviour of Gold During Processing of Porphyry and Refractory Copper-Gold Ore. Mineral Engineering (1997) C. Meyer et al. Wall Rock Alteration (1967)

(PDF) Environmental desulphurization of four Canadian mine tailings

2000年8月1日Environmental desulfurization by froth flotation is one of the strategies recommended by researchers as an integrated tailings management technique. It has been demonstrated to be economically and

FOH Institute of Physics

2021年2月10日with the tailings flotation classification being drained. A schematic diagram of flotation classification enrichment in a closed grinding cycle is presented, and the results of calculating final flotation classification parameters for sulphide copper ore dressing are presented. Unlike SkimAir flotation machines, flotation classifiers can

IMPROVED FLOTATION OF FINE PGM TAILINGS WITH A

complement rather than replace flotation size bubbles (Nesset et al., 2006). Research has shown that the ageing of micro (pico) bubbles as well as flotation sized bubbles was detrimental to particle-bubble attachment and that future the optimum flotation conditions would be obtained under conditions in which the two are co-generated.

Grade prediction of zinc tailings using an encoder-decoder

2021年10月1日The tailings of the first rougher are floated by rougher I, II and three-stage scavengers to produce the zinc tailings. To monitor the grades in this zinc flotation process, an XRF analyser and three digital cameras were installed. To save cost, the XRF analyser adopts a way of sampling multiplexer to measure the pulp grade by about 20 min.

Practical Importance of Tailings for Cemented Paste Backfill

2017年3月4日Cemented paste backfill (CPB) is an engineered mixture of fine process tailings (75–85% solids by weight), a hydraulic binder (3–9% by total dry paste weight) and mixing water for a solid density of 70–80% by weight (Fig. 2.3 ). The addition of a binder is essential for the strength and stability of CPB.

Mechanical Properties and Hydration Mechanism of Coal Flotation

2023年3月10日Large-scale application of filled coal mining technology has long been limited by conditions such as the cost of filling. Compared to traditional filling materials, coal flotation tailing filling materials (CFTFM) offers advantages such as low cost and excellent performance. The Box–Behnken response surface method was used to investigate the

Basic Considerations for the Reprocessing of Sulfidic Tailings

2018年5月1日It is illustrated that tailing remining and reprocessing are connected with both challenges and opportunities. The Bollrich tailing pond contains approximately 7 million tonnes of flotation...

Extraction of rare earth elements from upgraded phosphate

In this work, phosphate flotation tailings were upgraded by gravity separation and froth flotation. Gravity separation was conducted using a laboratory shaking table, while flotation was conducted in a Denver D-12 flotation cell. The concentrated tailings were then leached by nitric acid followed by REE extraction with solvent and ion-exchange

Minerals Free Full-Text Leaching of Manganese from Marine

2019年5月11日Based on the results obtained from a previous study investigating the dissolution of Mn from marine nodules with the use of sulfuric acid and foundry slag, a second series of experiments was carried out using tailings produced from slag flotation. The proposed approach takes advantage of the Fe present in magnetite contained in

The necessity of tailings flotation machine deepconenet

2015年3月2日The necessity of tailings flotation machine. Tailings refers to the waste slag in mining, smelting enterprises discharge, mostly mud efflux form, over the formation of the tailings. Because the library contained a large amount of hard exudates Whey, in the absence of tailings seepage dry, has a price component re-election, backfilling mined

Vale begins Gelado tailings re-use project commissioning with

2023年3月3日In addition to providing a sustainable destination for the tailings, the project will use 100% electric dredges to extract the material, avoiding CO2 emissions. The initial production capacity will be 5 Mt/y and the investment is $485 million.

Tailings solutions: How to filter down the options

Potential water recovery potentials for copper flotation tailings are shown in the below table. In Chile, current estimates for the cost of desalinated water pumped to the mine are as high as $5 per cubic meter or higher.

Challenges and opportunities in the recovery/rejection of trace

DOI: 10.1016/J.MINENG.2015.04.008 Corpus ID: ; Challenges and opportunities in the recovery/rejection of trace elements in copper flotation-a review @article{Agorhom2015ChallengesAO, title={Challenges and opportunities in the recovery/rejection of trace elements in copper flotation-a review}, author={Eric

Efficiency Assessment of Allflot Pneumatic Flotation Machines in

2021年7月20日The tests were carried out to evaluate the efficiency of the Pneuflot pneumatic flotation machine for the recovery of fine-grained gold from flotation tailings of a gold-processing plant and for

Operating practices in the beneficiation of major porphyry copper

The importance of the application of new technology for improvement in plant metallurgical results is highlighted. S. Bulatovic Flotation Behaviour of Gold During Processing of Porphyry and Refractory Copper-Gold Ore. Mineral Engineering (1997) C. Meyer et al. Wall Rock Alteration (1967)