Analysis Of Designing A Grinding Machine Principles Of Jaw Crushers Hammer Mills

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5]

CHAPTER 20: SIZE REDUCTION EQUIPMENT FOR SIZE

– Jaw crushers Gyratory crushers . Jaw crusher • Feed is admitted between two jaws, which are open at the top like V • One of the jaws is fixed and vertical, while the other is

principles of jaw crushers c hammer mills github

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

Lump Breakers and Crushers Archives Schutte Hammermill

Industrial hammer mills and jaw crushers are the size reduction equipment of choice for processing large, blocky and/or abrasive materials. Schutte-Buffalo offers an extensive

crusher/sbm hinged jaw crusher design mechanical

Contribute to yunan88/crusher development by creating an account on GitHub.

Designing Of Grinding Machines Crusher Mills, Cone Crusher, Jaw

post time:2012-04-08 view:96 Mining And Construction Machinery Ball Mill Design Ball Mills Design Ball mill design is high technology content, and Help design grinding

Hammer Crusher Design PDF Crusher Mills, Cone Crusher, Jaw

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT CRUSHER. β=specific particle size depending on the crusher design and granulate properties. Fig.4 A

DESIGNCONSTRUCTION OF HAMMER MILL MACHINE Afribary

2).Based on the literature review the concepts of hammer mill design will be developed. The concepts will be reviewed severally and sketches of various concepts made. Finally

Crusher an overview ScienceDirect Topics

Primary jaw crushers typically operate in open circuit under dry conditions. Depending on the size reduction required, the primary jaw crushers are followed by secondary and tertiary crushing. The last crusher in the line of operation operates in closed circuit.

(PDF) Comminution in mineral processing ResearchGate

2018年11月19日Rotor of hammer crusher rotates at the speed of 1500-1700 rpm and crushing speed reaches up to 1500 tph in case of limestone crushing (Michaud, 2016). It is perfect solution for moist rock such

principles of jaw crushers c hammer mills github

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT

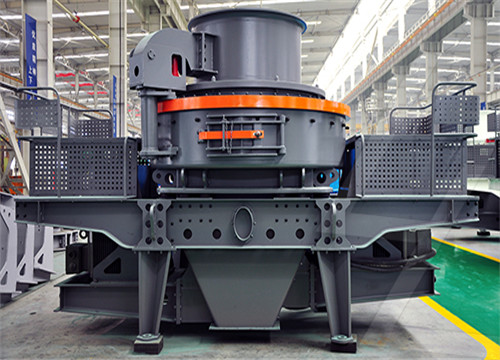

Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor, hammers, casing, and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacity and also do their analysis. Impact crushers involve the use of impact rather than pressure to crush materials.

crusher/sbm hinged jaw crusher design mechanical principles of

Contribute to yunan88/crusher development by creating an account on GitHub.

Grinding Mill, Ball Mill // Vipeak Heavy Industry

Vipeak Heavy Industry is the manufacturer of Jaw Crusher,Stone Crusher,Cone Crusher,Grinding Mill,Ball Mill,etc.With the latest manufacturing technology, the unique structural design,we produce the high standard, qualified stone crushers and grinding mills, we provide you the detailed information of Jaw Crusher,Stone Crusher,Cone

Hammer Mills Hosokawa Alpine

Hammer Mill To the machine High-speed hammer mills designed for continuous operation in harsh environments at peripheral speeds of up to 100m/s. Your contact Please tell us your area of interest and where you are from. Planning the entire process It’s not just building a machine we support your projects from consulting to maintenance. 01

sbm/sbm principles of jaw crushers hammer mills.md at master

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

Designing Of Grinding Machines Crusher Mills, Cone Crusher, Jaw Crushers

post time:2012-04-08 view:96 Mining And Construction Machinery Ball Mill Design Ball Mills Design Ball mill design is high technology content, and Help design grinding machine Practical Machinist Largest

Hammer Crusher Design PDF Crusher Mills, Cone Crusher, Jaw Crushers

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT CRUSHER. β=specific particle size depending on the crusher design and granulate properties. Fig.4 A Single particle just after with the rotor bar of a hammer crusher [1] 10.

Hammer Mills Crushing Machines JEHMLICH

This hammer mill is used for crushing rock salt in underground mining. The hammer mill is integrated in the on-site production line. The hammer mill is made of stainless steel to avoid corrosion. Design size: HM 671 Motor: 30 kW Operation with frequency inverter at 25-87 Hz Input material: rock salt Made of stainless steel

Stone Crushing Hammer Mill

2016年2月24日The SC Series Stone Crusher is a ruggedly constructed gravity discharge hammer mill, offering exceptional performance and value by eliminating the high cost of collecting and transporting stone scrap for disposal. Available in two standard sizes, the SC Series can reduce stone scrap to particle sizes ranging from chips to sand, resulting in an

Available online at sciencedirect ScienceDirect CORE

number of crushers available such as jaw, gyratory, cone, roll, and impact crushers [12]. Crushers are often located in underground mines where they reduce the size of rock, in situ, to a more manageable size for transport. Crushers are available in all types of configurations. Two types are illustrated in figure 3. Once crushed, the material

Comminution Wikipedia

Comminution is the reduction of solid materials from one average particle size to a smaller average particle size, by crushing, grinding, cutting, vibrating, or other processes. In geology, it occurs naturally during faulting in the upper part of the Earth's crust. In industry, it is an important unit operation in mineral processing, ceramics, electronics, and other

Crusher an overview ScienceDirect Topics

Primary jaw crushers typically operate in open circuit under dry conditions. Depending on the size reduction required, the primary jaw crushers are followed by secondary and tertiary crushing. The last crusher in the line of operation operates in closed circuit.

(PDF) Comminution in mineral processing ResearchGate

2018年11月19日Rotor of hammer crusher rotates at the speed of 1500-1700 rpm and crushing speed reaches up to 1500 tph in case of limestone crushing (Michaud, 2016). It is perfect solution for moist rock such

principles of jaw crushers c hammer mills github

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

Hammer Mills Crushing Machines JEHMLICH

This hammer mill is used for crushing rock salt in underground mining. The hammer mill is integrated in the on-site production line. The hammer mill is made of stainless steel to avoid corrosion. Design size: HM 671 Motor: 30 kW Operation with frequency inverter at 25-87 Hz Input material: rock salt Made of stainless steel

crusher/sbm hinged jaw crusher design mechanical principles of

Contribute to yunan88/crusher development by creating an account on GitHub.

Grinding Mill, Ball Mill // Vipeak Heavy Industry

Vipeak Heavy Industry is the manufacturer of Jaw Crusher,Stone Crusher,Cone Crusher,Grinding Mill,Ball Mill,etc.With the latest manufacturing technology, the unique structural design,we produce the high standard, qualified stone crushers and grinding mills, we provide you the detailed information of Jaw Crusher,Stone Crusher,Cone

sbm/sbm principles of jaw crushers hammer mills.md at master

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

Designing Of Grinding Machines Crusher Mills, Cone Crusher, Jaw Crushers

post time:2012-04-08 view:96 Mining And Construction Machinery Ball Mill Design Ball Mills Design Ball mill design is high technology content, and Help design grinding machine Practical Machinist Largest

Hammer Crusher Design PDF Crusher Mills, Cone Crusher, Jaw Crushers

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT CRUSHER β=specific particle size depending on the crusher design and granulate properties. Fig.4 A Single particle just after with the rotor bar of a hammer crusher [1] 10 Design of Hammer crusher and Main Shaft of Hammer Crusher

Jaw Crusher an overview ScienceDirect Topics

The ore is to be broken down in a jaw crusher to pass through a 11.5 cm screen. The undersize is scalped before feeding to the jaw crusher. Assuming the maximum feed rate is maintained at 30 t/h and the shapes of feed and product are the same and the crusher set is 10 cm, estimate the size of jaw crusher required and the production rate. Solution

HSE Quarries Safe operation and use of mobile jaw crushers

Mobile crushers are used in a wide range of industries, including quarrying, ore processing and recycling of demolition waste. This guidance is for all those with responsibilities for the operation of mobile crushers, including contract managers, supervisory staff and operators of these machines. It covers the safe operation of the mobile

Stone Crushing Hammer Mill

2016年2月24日Description The SC Series Stone Crusher is a ruggedly constructed gravity discharge hammer mill, offering exceptional performance and value by eliminating the high cost of collecting and transporting stone scrap for disposal.

Available online at sciencedirect ScienceDirect CORE

number of crushers available such as jaw, gyratory, cone, roll, and impact crushers [12]. Crushers are often located in underground mines where they reduce the size of rock, in situ, to a more manageable size for transport. Crushers are available in all types of configurations. Two types are illustrated in figure 3. Once crushed, the material

Comminution Wikipedia

Comminution is the reduction of solid materials from one average particle size to a smaller average particle size, by crushing, grinding, cutting, vibrating, or other processes. In geology, it occurs naturally during faulting in the upper part of the Earth's crust. In industry, it is an important unit operation in mineral processing, ceramics, electronics, and other