Mining Impact Crusher For Maintenance And Consumable

IMPACT CRUSHERS

Underground Mining. A highly specialized partner, offering the mining industry technically proven solutions for a vast array of applications English; Español; Deutsch;

进一步探索

Spare parts APS Secondary Impactor Hazemag North America根据热度为您推荐•反馈

Impact Crushers Primary McLanahan

McLanahan offers a wide selection of Impact Crushers for quarried limestone and semi-abrasive minerals. McLanahan draws from the 75 years of field experience with the

进一步探索

Used Roll Crusher for sale. Pioneer equipmentmore MaSmall Jaw Crusher For Sale Low Cost Of Mini Jaw Crusher根据热度为您推荐•反馈

Crusher wear parts Metso Outotec

Select the right wear part solution for your demands. From classic crushing to high-volume, high-value operation, Metso Outotec has more than just crusher wear parts and

Avoid Unplanned Downtime: 5 Crusher Maintenance Best

There are three approaches to maintenance: reactive, preventative and predictive. Reactive is repairing something that has failed. Preventative maintenance is often viewed as

MVT-II 600 Mining Sizers Komatsu

Reduce fines and abrasive wear. Secondary sizers use matched velocity technology (MVT) to minimize fines. Timed center-sizing rolls enable teeth to mesh together and control

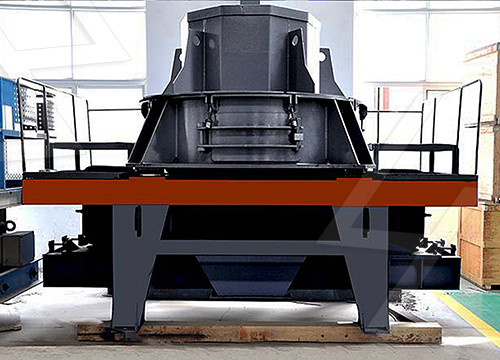

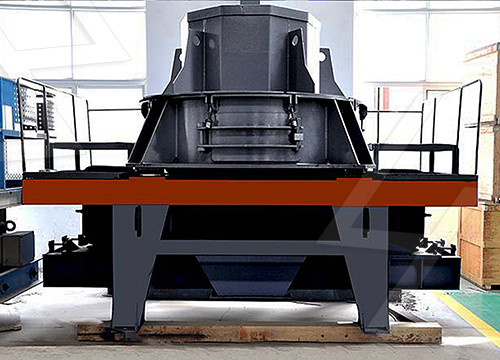

Impact Crushers Precise Shape Of Cubical End Crushed

DOVE Impact Rock Crushers are effectively employed for medium and fine crushing of materials with compressive strength less than 300 MPS such as Granite, Marble, Iron

4 Types of Stone Crushers' Maintenance and Efficient

2023年2月15日The regular maintenance and repair include adjustment of the gap between the rotor of the impact crusher and the impact lining plate, replacement of

AMIT 129: Lesson 12 Crusher and Mill Operation Safety

Hazards during maintenance are many including falls, being caught in moving equipment and being crushed by heavy components. Recently an overseas operator with more than

Crusher Maintenance, Laser Cutting Services, Plasma Cutting

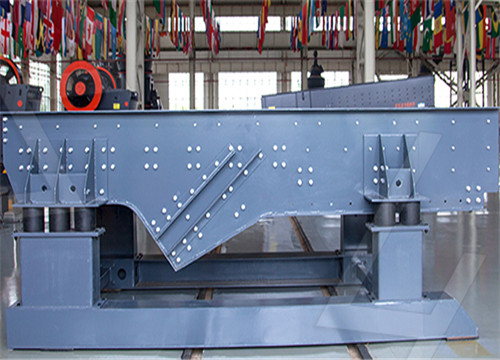

We can provide: Crusher Maintenance and Services. Wear Liner Packages. Laser and Plasma Cutting Services. Apron Feeder Maintenance and Services. Conveyor

® NP Series™ impact crushers Metso Outotec

® NP Series™ horizontal shaft impact (HSI) crushers are known for high reduction ratios when processing all type materials. They deliver unbeatable performance in primary, secondary and tertiary crushing in aggregates production, mining operations, as well as recycling applications. Contact our sales experts High performance

Rock Crushers, Stone Crushers, Screening and

We offer mining jaw crushers, cone crushers, impact crushers, roll crushers and primary gyratory crushers for mining, quarrying and aggregate production. Our extensive expertise ranges from greenfield

Impact Crushers Primary McLanahan

The VersaCap R-Series Impactor is designed for highly friable material like concrete rubble, and performs well in a single-crusher closed circuit. The material passing through the VersaCap Impactor is conveyed to a screen, where the oversized material is then directed back to the VersaCap.

MVT-II 600 Mining Sizers Komatsu

Reduce fines and abrasive wear. Secondary sizers use matched velocity technology (MVT) to minimize fines. Timed center-sizing rolls enable teeth to mesh together and control product size in three dimensions. Shaft assemblies include cast wear segments with replaceable teeth for extended life. Picks designed with long-lasting wear segments.

Avoid Unplanned Downtime: 5 Crusher Maintenance Best

“According to leading aggregate producers, repairs and maintenance labor average 30 to 35 percent of direct operating costs,” says Erik Schmidt, Resource Development Manager, Johnson Crushers International, Inc. “That’s a pretty large factor towards the overhead of that equipment.

What Type of Crusher Is Best for Primary Crushing?

2021年3月25日These types of compression crushers are best suited for heavy mining, quarried materials, sand and gravel, and recycling applications. They provide a reduction ratio of 3:1 to 6:1. Jaw Crushers

Tips to maximize crushing efficiency PitQuarry

2019年5月13日It is a good rule to maintain about 10 to 15 percent of material finer than the closed-side setting in the feed to assist crushing action. More than 10 to 15 percent will likely cause ring bounce due to the pressures in the

Surface mining industry Komatsu

Looking for a trusted partner to help optimize your surface mining operations from mine-to-mill? With a full line of innovative solutions and more than a hundred years of industry experience, our experts work with you to identify the right combination of surface equipment and technologies for your mining processes, creating lasting value for your business.

IROCK Crushers Home IROCK Crushers

2023年3月6日The IROCK TJ-2745 Mobile Jaw Crusher provided ease of access, maintenance and versatility to increase production. California Rock Crusher (CalCrush) is a turn-key portable service provider for aggregate mining, concrete, asphalt, block and recycling. Magruder’s most recent aggregate operation utilizes IROCK’s TC-20

Industrial Crusher maintenance and rebuilds Prime

Prime has been rebuilding cone crushers for the mining industry for more than 35 years. Main frames, bowls, adjustment rings, eccentric housings we comprehend the purpose each component and rebuild for performance.

ANALYSIS OF FAILURE STATISTICS FOR CONE CRUSHER

correction of problems. The model will contribute to improve the maintenance indicators and based on the consequences, decisions may be taken to promote the plant’s maintenance strategy and improving crusher reliability. THE EQUIPMENT Cone crushers are extensively used for rock breakage and as a secondary crusher or tertiary crusher in a

Crusher Maintenance, Laser Cutting Services, Plasma Cutting

We can provide: Crusher Maintenance and Services. Wear Liner Packages. Laser and Plasma Cutting Services. Apron Feeder Maintenance and Services. Conveyor Maintenance. Underground Mining Maintenance. Underground Ladderways. Rising Main Ladderways, Hangers, PipingScaling Bars.

mining impact crusher for maintenance and consumable

Mining Impact Crusher For Maintenance And Consumable Feb 28, 2013 Themonly used model for a crusher spares plan begins with categorizing your operations parts into four areas The goal of this exercise should be to create an inventory of the right parts so as to minimize the potential of extended downtime, while at the same time not.

Regular crusher maintenance integral to International Mining

2017年8月8日Performing regular maintenance on crushers is integral to the reliability, performance and output they achieve. Prevention is better than cure; by carrying out regular inspections operators will ensure their crusher runs for a longer period of time with minimal unscheduled downtime.

® NP Series™ impact crushers Metso Outotec

® NP Series™ horizontal shaft impact (HSI) crushers are known for high reduction ratios when processing all type materials. They deliver unbeatable performance in primary, secondary and tertiary crushing in aggregates production, mining operations, as well as recycling applications. Contact our sales experts High performance

Impact Crushers Primary McLanahan

The VersaCap R-Series Impactor is designed for highly friable material like concrete rubble, and performs well in a single-crusher closed circuit. The material passing through the VersaCap Impactor is conveyed to a screen, where the oversized material is then directed back to the VersaCap.

MVT-II 600 Mining Sizers Komatsu

Minimize fines and wear with matched velocity technology (MVT) that aligns the tooth speed of the roll with the velocity of the mineral falling through the crusher. Control and optimize product size Timed shafts and oil gap adjustment enables control of product size to minimize transfer issues to chutes, transfer points and conveyor belts.

Surface mining industry Komatsu

In your efforts to maximize productivity, you can rely on a world leader in mining trucks, electric and hybrid rope shovels, wheel loaders, blasthole drills, hydraulic excavators, dozers, walking draglines, automation solutions and connected mining technologies.

Tips to maximize crushing efficiency PitQuarry

2019年5月13日It is a good rule to maintain about 10 to 15 percent of material finer than the closed-side setting in the feed to assist crushing action. More than 10 to 15 percent will likely cause ring bounce due to the pressures in the

IROCK Crushers Home IROCK Crushers

2023年3月6日The IROCK TJ-2745 Mobile Jaw Crusher provided ease of access, maintenance and versatility to increase production. California Rock Crusher (CalCrush) is a turn-key portable service provider for aggregate mining, concrete, asphalt, block and recycling. Magruder’s most recent aggregate operation utilizes IROCK’s TC-20

Raptor® Cone Crusher a gamechanger for both

Raptor® Cone Crushers for Mining; TST Jaw Crusher; Impact crushers Impact crushers. EV Hammer Impact Crusher; Strike-Bar™ Crusher; Crusher maintenance services. Upgrades and Retrofits.

Industrial Crusher maintenance and rebuilds Prime

Prime has been rebuilding cone crushers for the mining industry for more than 35 years. Main frames, bowls, adjustment rings, eccentric housings we comprehend the purpose each component and rebuild for performance.

Crusher Maintenance, Laser Cutting Services, Plasma Cutting

We can provide: Crusher Maintenance and Services. Wear Liner Packages. Laser and Plasma Cutting Services. Apron Feeder Maintenance and Services. Conveyor Maintenance. Underground Mining Maintenance. Underground Ladderways. Rising Main Ladderways, Hangers, PipingScaling Bars.

mining impact crusher for maintenance and consumable

Mining Impact Crusher For Maintenance And Consumable Feb 28, 2013 Themonly used model for a crusher spares plan begins with categorizing your operations parts into four areas The goal of this exercise should be to create an inventory of the right parts so as to minimize the potential of extended downtime, while at the same time not.

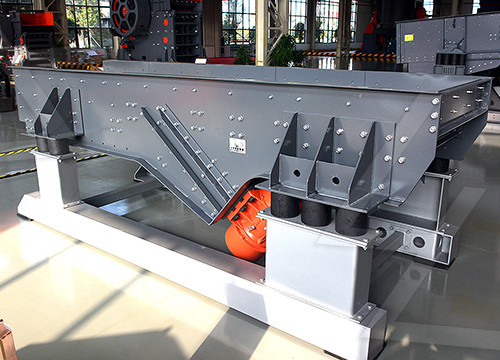

Crusher an overview ScienceDirect Topics

The impact crusher ( Fig. 13.15) employs high-speed impact or sharp blows to the free-falling feed rather than compression or abrasion. It utilizes hinged or fixed heavy metal hammers (hammer mill) or bars attached to the edges of horizontal rotating discs.

Protective Coatings Success Stories for Mining and Ore

Impacts: Crushers, Grinding Mills 3 Equipment/Structure Wear In Mining Operations Few industries take as much of a toll on equipment and structures as mining and ore processing. Recognizing that impact—and preventing it before it occurs to new equipment—can reduce unplanned downtime and improve plant productivity levels.