Grinding Balls Mining Rod Mill Mb0918

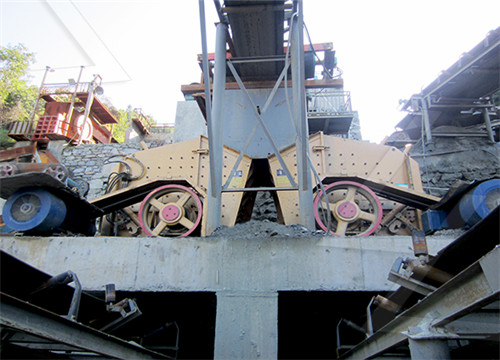

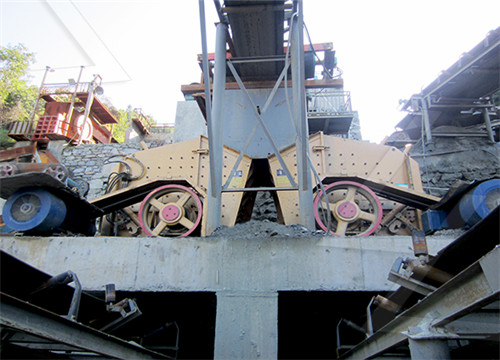

Fine and Coarse Grinding Rod Mill for Benefication

Fine and Coarse Grinding Rod Mill for Benefication Equipment (MB0918), Find Details and Price about Rod Mill Grinding Rod Ball Mill from Fine and Coarse Grinding Rod Mill

Grind Molycop

With a wear performance up to 25% longer than the standard High Carbon Grinding Rod, the HTR50 has outstanding resilience and a hardness

Grinding mills SKF

SKF offers solutions for autogenous mills, ball mills, high pressure grinding rolls, rod mills, SAG mils and horizontal grinding mills. The solutions are designed to protect

Grinding Mills Mineral Processing Equipment CITIC HIC

To date, CITIC HIC has cumulatively produced and delivered over 1,550 mineral grinding mills, with a total installed power of 3,900MW. Our large-size grinding mills hold a market share of 85% in the domestic mining

Grinding BallsRods Mineral ProcessingMetallurgy

2016年10月20日GRINDING BALLS Grinding Balls are forged from the best high-carbon manganese steel and are non-breakable. These balls are of the very highest quality that can be produced, and give long,

Grinding Mills Westpro Machinery

Grinding Mills. Westpro’s heavy duty grinding mills are designed for durability and excellent grinding performance in mining applications. 6ft Diameter x10ft Ball and Rod

Rod Mills Grinding Mills DOVE

DOVE supplies 2 models of small Rod Mills designed for laboratories milling process, capacity range of (5000g/Hr 20 Kg/Hr). For small to large scale grinding operations,

Rod Mill Grinding Rods 911metallurgist

Rod mill grinding rods of all sizes and length. High hardness, range is 45~55HRC Low bending, less than 1.5mm/m Dense microstructure,Bainite +Pearlite+Carbide Low breakage rate, more than 15000 times/ 3.5m Low

Ball Mill RETSCH powerful grinding and homogenization

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were

Rod Mill (MB0918/MB0924/MB1224) China Rod Mill and Bar Mill

MB0918, MB0924, MB1224 Liner Steel, Ceramic, Rubber Capacity 0.5-100t Package Container, Flatrack, in Bulk, Standard Power Min. 18.5kw Certificate ISO9001 Grinding Material Ore, Ceramic, Cement, etc. Installation Guide by Engineer at Site Service Whole Using Life Transport Package Suitable for Ocean Shipping Specification ISO9001: 2000

AMIT 135: Lesson 6 Grinding Circuit Mining Mill

Objectives. At the end of this lesson students should be able to: Explain the grinding process. Distinguish between crushing and grinding. Compare and contrast different type of equipment and their components used for

Rod Mills for coarse grinding

Volumetric loading is similar to that of a ball mill (30-35%) Design standards for drive components are more demanding than ball mills; Dry applications feature a peripheral discharge or an air-swept arrangement; Typical

Grinding Mills Mineral Processing Equipment CITIC

To date, CITIC HIC has cumulatively produced and delivered over 1,550 mineral grinding mills, with a total installed power of 3,900MW. Our large-size grinding mills hold a market share of 85% in the domestic mining

Essa laboratory ball and rod mills

The Essa® ball and rod mill range includes: Essa® BM Series Laboratory Ball Mills ideal for producing finer particles. Available in 6.3 L, 12.3 L and 21 L barrel volumes. Essa® RM Series Laboratory Rod Mills suitable

AMIT 135: Lesson 8 Rod Mills Mining Mill

Typically R = 8. Rod Mill Charge: Typically 45% of internal volume; 35% 65% range. Bed porosity typically 40%. Height of bed measured in the same way as ball mills. Bulk density of rods = 6.25 tons/m3. In wet grinding,

Rod Mills Grinding Mills DOVE

DOVE supplies 2 models of small Rod Mills designed for laboratories milling process, capacity range of (5000g/Hr 20 Kg/Hr). For small to large scale grinding operations, DOVE Rod Mills are supplied in 9 models, capacity range of (3 TPH 180 TPH). With over 50 years experience in Grinding Mill Machine fabrication, DOVE Rod Mills as

Rod Mill Grinding Rods 911metallurgist

Rod mill grinding rods of all sizes and length. High hardness, range is 45~55HRC Low bending, less than 1.5mm/m Dense microstructure,Bainite +Pearlite+Carbide Low breakage rate, more than 15000 times/ 3.5m Low

Rod Mill with Good Price for Mining Industrial Ore

Rod Mill Feeding size: ≤50mm Capacity: 0.62-180t/h Output size: 0.833-0.147mm Applications: Rod mills are widely used in refractory, chemical, metallurgy, glass and other industries. Especially suitable for grinding

Rod mill_The NIle Machinery Co.,Ltd

The use of advanced controllable material rod grinding machine technology, user's abrasive materials with appropriate grinding rods, a change of the traditional ball mill surface contact for line contact, use

Grinding mills SKF

SKF offers solutions for autogenous mills, ball mills, high pressure grinding rolls, rod mills, SAG mils and horizontal grinding mills. The solutions are designed to protect pinions and trunnions and prevent failure in these harsh operating conditions helping you improve reliability and safety while reducing maintenance and operating costs.

Ball Mill Grinding Media For Copper Mining Supplier's Choice

Quality Ball Mill Grinding Media For Copper Mining Supplier's Choice find quality Grinding Media, CastForgedGrinding Media from Zhangqiu Taitou Special Steel Ball Factory of China Suppliers .

Rod Mill,Rod,Mill,The,rod,Mill,has,two,_The NIle Machinery Co.,Ltd

The use of advanced controllable material rod grinding machine technology, the actual user's abrasive materials with appropriate grinding rods, a change of the traditional ball mill surface contact for line contact, the use of more uniform particle size, production improved nearly 50% Technical Data Request For Quotation HOME PRODUCTS CASE

Supplier ball forged bar rod steel cast grinding mine mill mining

FORGED BALLS. Grinding Balls in alloy steel rolled and/or stamped. We supply balls on a wide and complete range of hardnesses, with different hardness profiles, to maximize the grinding performance in wear rate and impact endurance, at a regular wear and with tailor-made alloys according to the mill and milling material needs.

Rod Mill (MB0918/MB0924/MB1224) China Rod Mill and Bar Mill

MB0918, MB0924, MB1224 Liner Steel, Ceramic, Rubber Capacity 0.5-100t Package Container, Flatrack, in Bulk, Standard Power Min. 18.5kw Certificate ISO9001 Grinding Material Ore, Ceramic, Cement, etc. Installation Guide by Engineer at Site Service Whole Using Life Transport Package Suitable for Ocean Shipping Specification ISO9001: 2000

Grinding mills SKF

SKF offers solutions for autogenous mills, ball mills, high pressure grinding rolls, rod mills, SAG mils and horizontal grinding mills. The solutions are designed to protect pinions and trunnions and prevent failure in these harsh operating conditions helping you improve reliability and safety while reducing maintenance and operating costs.

AMIT 135: Lesson 6 Grinding Circuit Mining Mill

Objectives. At the end of this lesson students should be able to: Explain the grinding process. Distinguish between crushing and grinding. Compare and contrast different type of equipment and their components used for

Rod Mills for coarse grinding

Volumetric loading is similar to that of a ball mill (30-35%) Design standards for drive components are more demanding than ball mills; Dry applications feature a peripheral discharge or an air-swept arrangement; Typical

Essa laboratory ball and rod mills

The Essa® ball and rod mill range includes: Essa® BM Series Laboratory Ball Mills ideal for producing finer particles. Available in 6.3 L, 12.3 L and 21 L barrel volumes. Essa® RM Series Laboratory Rod Mills suitable

Grinding Mills Mineral Processing Equipment CITIC

To date, CITIC HIC has cumulatively produced and delivered over 1,550 mineral grinding mills, with a total installed power of 3,900MW. Our large-size grinding mills hold a market share of 85% in the domestic mining

AMIT 135: Lesson 8 Rod Mills Mining Mill

Typically R = 8. Rod Mill Charge: Typically 45% of internal volume; 35% 65% range. Bed porosity typically 40%. Height of bed measured in the same way as ball mills. Bulk density of rods = 6.25 tons/m3. In wet grinding,

Rod Mills Grinding Mills DOVE

DOVE Rod Mills are highly efficient grinding mills commonly used in minerals processing and particle size reduction through friction, attrition and compressive forces, designed to grind and blend various bulk material ranging from soft, fibrous to hard and brittle material.

Rod Mill Grinding Rods 911metallurgist

Rod mill grinding rods of all sizes and length. High hardness, range is 45~55HRC Low bending, less than 1.5mm/m Dense microstructure,Bainite +Pearlite+Carbide Low breakage rate, more than 15000 times/ 3.5m Low

Ball Mill Grinding Media For Copper Mining Supplier's Choice

Quality Ball Mill Grinding Media For Copper Mining Supplier's Choice find quality Grinding Media, CastForgedGrinding Media from Zhangqiu Taitou Special Steel Ball Factory of China Suppliers .

Rod Mill,Rod,Mill,The,rod,Mill,has,two,_The NIle Machinery Co.,Ltd

The use of advanced controllable material rod grinding machine technology, the actual user's abrasive materials with appropriate grinding rods, a change of the traditional ball mill surface contact for line contact, the use of more uniform particle size, production improved nearly 50% Technical Data Request For Quotation HOME PRODUCTS CASE

High Efficient Mining Ball Mill Machine Prices For Mineral Grinding

3666*1835*1400 Weight: 4265 KG Warranty: 1 Year Keywords: ball mill prices installation: technical guidance price: negotiable Color: white Application: Ore Usage: mining ball mill Feeding size: 0-25mm Output size: 0.074-0.4mm Supply Ability Supply Ability: 60 Set/Sets per Month PackagingDelivery Packaging Details Naked Port

Steel Grinding Balls for Sale, Grinding RodsCylpebs for Grinding Mill

Steel Grinding Balls. 1. Cast grinding balls. Chromium content: 1% 28%. Hardness: HRC40-60. Diameter: 10mm-150mm. Features: after heat treatment, it has high hardness, grinding resistance and no loss of roundness. Application: cast grinding balls are widely used in ball mill grinding systems in mining, cement, building materials, chemical