Screen Separators At The Mining Mill

Screening, Separation and Vibration Mining Technology

Mining Technology has listed the leading suppliers of a range of screening, classifying and separation equipment, parts and services. The list includes manufacturers and suppliers

AMIT 145: Lesson 3 Dense Medium Separation Mining

DM VesselsMedium-To-Coal RatioSeparation DensityEfficiency vs. Particle SizeMagnetite Amount RequiredMagnetite LossesRinse Water Requirements

Typically, sprays are used for the coarse products where the total screen area is low while shower boxes are employed in fine particle rinsing.Water is added in stages. About 4/5ths of the water is recirculation water, generally from the overflow of the magnetic separators.Clean water is added in the last sprays/boxes just prior to discharging the screen. Typically, sprays are used for the coarse products where the total screen area is low while shower boxes are employed in fine particle rinsing.Water is added in stages. About 4/5ths of the water is recirculation water, generally from the overflow of the magnetic separators.Clean water is added in the last sprays/boxes just prior to discharging the screen.The capacity of a drain-and-rinse screen can be estimated by the Sauter diameter, which is a measurement based on the amount of particle surface area.展开选择时,新内容将添加到焦点当区域上方在millopsmunity.uaf.edu上查看更多信息

进一步探索

Dense Medium Separation SlideShareDense Medium Separation (DMS) Academia.edu根据热度为您推荐•反馈

Mechanical screening Wikipedia

OverviewGeneral categoriesApplicationsProcessPhysical principlesScreening terminologyTypes of mechanical screeningScreen Media Attachment Systems

Mechanical screening, often just called screening, is the practice of taking granulated or crushed ore material and separating it into multiple grades by particle size. This practice occurs in a variety of industries such as mining and mineral processing, agriculture, pharmaceutical, , , and recycling. A method of separating solid particles according to size alone is called screening.

Advances in screening technology in the mining sector

Summary: In today’s crushing and grinding circuits in the mining sector the bottleneck is no longer the comminution plant but the classification system. The increasing demands on

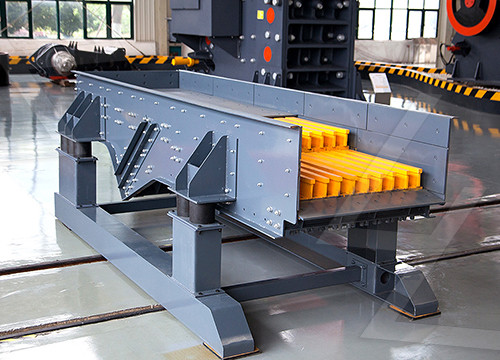

Mining Vibrating Screens and Rectangular Separator

Rare earth. Uranium. These models of rectangular screeners and separators are designed and oriented to improve mining materials processes by separating different materials

Dense Media Separation (DMS) Plants JXSC Machine

2022年2月17日Dense Media Separation. A heavy medium is a heavy-fluid or heavy suspension fluid with a density greater than that of water (1g/cm3). The process of separating ore particles in heavy media is

Mill liners Metso Outotec

Liners for all sections of various types of mills. Metso Outotec designs mill linings for optimal grinding performance. We offer fit for purpose liners for all types of mills, including SAG

AMIT 145: Lesson 4 Gravity Separation Mining Mill

Mining Mill Operator Training. CMI Stokes TBS Separator [image 145-4-10] Typical throughput capacity of around 1.0 — 2.0 tons/hr/ft 2. Rotating bowl contains a cylindrical screen with a lip, whose height can be

Mining Screens Multotec

Multotec mining screens are used in sorting, classifying, dewatering, scalping, and desliming applications, with one of the world’s largest ranges of rubber, polyurethane, wedge wire, steel and combination ( Polywedge

Trommel screen Wikipedia

A trommel screen, also known as a rotary screen, is a mechanical screeningmachine used to separate materials, mainly in the mineraland solid-waste processing industries.[1] It consists of a perforated cylindrical drum that is normally

Mineral processing Wikipedia

Mineral processing. Crushing, a form of comminution, one of the unit operations of mineral processing. In the field of extractive metallurgy, mineral processing is the process of separating commercially valuable

AMIT 145: Lesson 3 Dense Medium Separation

This rule is based on a separation gravity below 1.55 and a 50% yield to the product stream. DM Vessel Width The width is based on the capacity of the flight conveyors which can be estimated by the following table. Capacity

Hydrocyclones McLanahan

This is typically done in the form of an Ultra Fines Recovery system comprised of a Sump, Pump, Cyclones and Dewatering Screen, which will have a discharge to waste nominally 90% passing 400 mesh (38µm) and

Centrifugal DewateringSeparating Equipment

The Kason Difference. With over 50 years of manufacturing excellence, Kason Corporation has an expansive range of. screening and separating solutions from standard, off-the-shelf options to highly customized built

Vibrating Screen Working Principle Mineral

2015年7月26日When the smaller rock has to be classified a vibrating screen will be used. The simplest Vibrating Screen Working Principle can be explained using the single deck screen and put it onto an inclined

AMIT 135: Lesson 2 Circuit Mass Balancing Mining

Objectives. Upon completion of this lesson students should be able to: Differentiate between different type metallurgical accounting methods and benefit of metallurgical accounting. Recall the definitions of grade,

11.19.1 Sand And Gravel Processing US EPA

washers, screens, and classifiers to segregate particle sizes; crushers to reduce oversized material; and storage and loading facilities. A process flow diagram for construction sand and gravel processing is presented in Figure 11.19.1-1. The following paragraphs describe the process in more detail.

Magnetic Separators For Mineral Processing JXSC Mining

2023年3月9日The magnetic separator can recycle the magnetic medium powder used in the production process, which greatly improves production efficiency. Reduce floor space and reduce labor costs. 3. Mineral purification high utilization rate It is often used in quartz sand, potassium feldspar, albite and other industries.

industrial separating screens MiningQuarry Plant

2013年3月20日Vibratory Round Separators and Screening Equipment from the world leader in industrial screens, classifying and sifting equipment Kebby Industries, Inc. Supplier of dust, screen, separating Kebby Industries, Inc. is an industrial supplier of dust, screen, separating, water.

sweco vibrating screen MiningQuarry Plant

2013年4月17日We supply used screens and screening equipment to the mining processing, minerals processing, chemical processing, Sweco 60 stainless steel screen. Vibrating screens SWECO SoftGeo Vibrating screens are used to separate solid substances from liquids and/r sorting of dry materials by particle size. SWECO brand

Types of Classifiers in Mineral Processing

2016年5月26日Rake Classifier. The Rake Classifier is designed for either open or closed circuit operation. It is made in two types, type “C” for light duty and type “D” for heavy duty. The mechanism and tank of both units are of sturdiest construction to meet the need for 24 hour a day service. Both type “C” and type “D” Rake Classifiers

Planetary Ball Mill JXSC Machine

Planetary ball mill is mainly used in fine grinding operations such as soil, geology, environmental protection, third-party testing, agriculture and animal husbandry, agricultural product quality, resources and environment, heavy metal analysis, or laboratory dry and wet research materials.

Introduction to Cyclones AusIMM

The mechanism described above is not precise as opposed to, say, a screen where the majority of particles smaller than the screen aperture pass through, and larger particles are retained. With a screen the cutpoint is very obvious if the screen has an aperture of 1mm, then its coarse product will be mostly +1mm, and its fine product all -1mm.

AMIT 145: Lesson 3 Dense Medium Separation

This rule is based on a separation gravity below 1.55 and a 50% yield to the product stream. DM Vessel Width The width is based on the capacity of the flight conveyors which can be estimated by the following table. Capacity

Hydrocyclones McLanahan

This is typically done in the form of an Ultra Fines Recovery system comprised of a Sump, Pump, Cyclones and Dewatering Screen, which will have a discharge to waste nominally 90% passing 400 mesh (38µm) and

Centrifugal DewateringSeparating Equipment Kason Corporation

The Kason Difference. With over 50 years of manufacturing excellence, Kason Corporation has an expansive range of. screening and separating solutions from standard, off-the-shelf options to highly customized built-to-spec equipment. Our products are designed to the highest possible standards so that they consistently exceed the expectations

Screening 101 Mineral ProcessingMetallurgy

2016年6月10日Screening 101. Screening is the passing of material through definite and uniform apertures is the only true and accurate means of grading to a required particle size. Air separation and hydraulic classification depend upon gravity and particle shape, and result in the segregation and retention of material of higher specific gravity and lower

Vibrating Screen Working Principle Mineral Processing

2015年7月26日When the smaller rock has to be classified a vibrating screen will be used. The simplest Vibrating Screen Working Principle can be explained using the single deck screen and put it onto an inclined frame. The frame is mounted on springs. The vibration is generated from an unbalanced flywheel. A very erratic motion is developed when this

AMIT 135: Lesson 2 Circuit Mass Balancing Mining Mill

Objectives. Upon completion of this lesson students should be able to: Differentiate between different type metallurgical accounting methods and benefit of metallurgical accounting. Recall the definitions of grade, recovery, yield and other characteristics used in mass balancing. Recognize the application of two product formula for balancing.

11.19.1 Sand And Gravel Processing US EPA

washers, screens, and classifiers to segregate particle sizes; crushers to reduce oversized material; and storage and loading facilities. A process flow diagram for construction sand and gravel processing is presented in Figure 11.19.1-1. The following paragraphs describe the process in more detail.

Magnetic Separators For Mineral Processing JXSC Mining

2023年3月9日The magnetic separator can recycle the magnetic medium powder used in the production process, which greatly improves production efficiency. Reduce floor space and reduce labor costs. 3. Mineral purification high utilization rate It is often used in quartz sand, potassium feldspar, albite and other industries.

screen mesh sizes crusher MiningQuarry Plant

2013年3月7日manufacturer: u screen model: ax500 year: 2007 price: $15,000 location: florida serial number: 1u9pr hours: 705 condition: used general information: used Wire Mesh Hexagonal Wire Mesh, Screen Crimped Wire Mesh

industrial separating screens MiningQuarry Plant

2013年3月20日Vibratory Round Separators and Screening Equipment from the world leader in industrial screens, classifying and sifting equipment Kebby Industries, Inc. Supplier of dust, screen, separating Kebby Industries, Inc. is an industrial supplier of dust, screen, separating, water.

Mineral processing Wikipedia

Mineral processing. Crushing, a form of comminution, one of the unit operations of mineral processing. In the field of extractive metallurgy, mineral processing is the process of separating commercially valuable minerals from their ores. [1] Depending on the processes used in each instance, it is often also known as ore dressing or ore milling .

What is the major step in the process of open-pit and underground mining?

2023年3月10日Published Mar 10, 2023. + Follow. Typically, the steps of open-pit and underground mining include 1. Exploration and assessment of the resource 2. Development of a mine plan 3. Construction of

small sweco screens separators mining github

Contribute to jidafang2022/en development by creating an account on GitHub.

Planetary Ball Mill JXSC Machine

Planetary ball mill is mainly used in fine grinding operations such as soil, geology, environmental protection, third-party testing, agriculture and animal husbandry, agricultural product quality, resources and environment, heavy metal analysis, or laboratory dry and wet research materials.