Solutions Project Report Of Clinker Grinding Mill Unit

Cement Grinding Plant CHAENG

Cement clinker grinding unit, or called cement grinding plant, cement grinding station, is an individual grinding plant in the finished cement production. Cement grinding plants

sbm/sbm project report on clinker grinding benin.md at

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Clinker grinding unit CHAENG

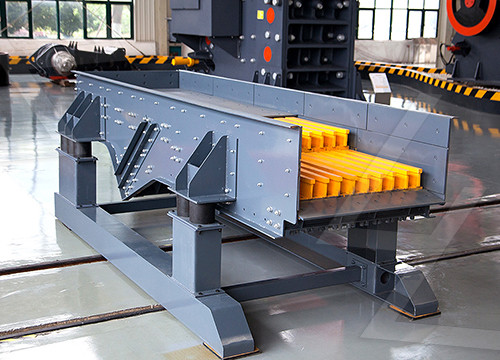

1.Clinker Grinding System Various materials are quantitatively given in the cement batching process according to the set ratio. After the materials are discharged

github

solutions project report of clinker grinding mill unit. Clinker grinding unit project report. Clinker grinding unit project report.project report on normal grinding

mill/sbm clinker grinding project report malaysia.md at master

You've already forked mill 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity You can not select more than 25 topics Topics must start with a letter or number,

project report for 1000 tpd capacity clinker grinding unit

project report of clinker grinding unit in india YouTube. 55 .first unit was setup at Porbandar with a capacity of 1000 tones 2. how to set up a clinker grinding unit

Project Report on CEMENT GRINDING UNIT Manufacturing

CEMENT GRINDING UNIT The project report includes Present Market Position and Expected Future Demand, Market Size, Statistics, Trends, SWOT Analysis and

Solutions Project Report Of Clinker Grinding Mill Unit

clinker grinding unit of 100tpd vaikuendokrinologija.lt Clinker Grinding Mill Machine sagami-souzoku. Introduction to cement clinker grinding unit project report The

Breakthrough in Clinker Grinding Massachusetts Institute

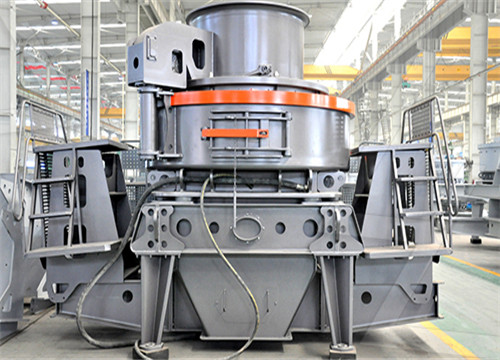

2012年11月8日grinding seeks to reduce materials from roughly one meter cubes of blasted stone to a size where at least 80 percent of the raw material is less than 75 microns. Finish grinding of clinker and other cement ingredients reduces 25 mm clinker balls to particle sizes optimally ranging from 3 to 30 microns. The

(PDF) CONVENTIONAL CLINKER GRINDING -A NEW

2020年4月29日This model enables the prediction of the electrical power consumption in clinker grinding (cement production), which contributes significantly to the cement production cost. Furthermore, the above

AVAILABLE AND EMERGING TECHNOLOGIES FOR

Grinding of clinker, together with additions of approximately 5 percent gypsum to control the setting properties of the cement can be done in ball mills, ball mills in combination with roller presses, roller mills, or roller presses. While vertical roller mills are feasible, they have not found wide acceptance in the U.S. Coarse

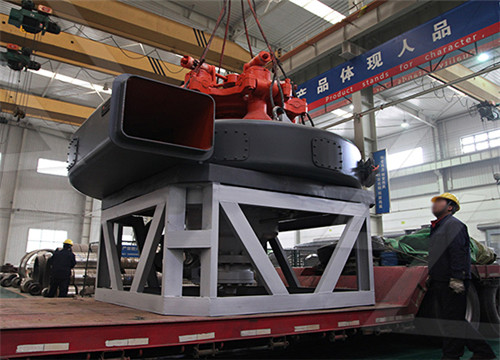

Clinker Grinding Unit Great Wall

Therefore, Clinker Grinding Unit system has simple technology, low failure rate, high operation efficiency, compact allocation, construction area of 70% of ball mill, construction space of 50-60% of ball mill, and it can help enterprises to save land resources effectively. 3. With excellent environmental benefit, low noise, and low dust.

Cement Grinding Plant CHAENG

The cement grinding unit produced by Xinxiang Great Wall Machinery integrates drying, grinding, powder classification, dust removal, and cement packaging. We can provide cement grinding units with different capacities and different equipment. Capacity: 20-380t/h Feeding Granularity: ≤25mm

Radiotracer Investigation of Clinker Grinding Mills for

Fig. 1: Design of clinker grinding system; mill and separator Fig. 2: External view of Mill 4 (left) and mill 3 (right) at GHACEM machine design and/or choosing optimal operating and

github

solutions project report of clinker grinding mill unit. Clinker grinding unit project report. Clinker grinding unit project report.project report on normal grinding machine pdf is

mill/sbm clinker grinding project report malaysia.md at master mill

You've already forked mill 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long. 1 Commit. 1 Branch. 0 Tags mill / sbm clinker grinding projec...

Project Report on cement grinding unit Manufacturing Plant,

Portland cement clinker is made by heating, in a kiln, a homogeneous mixture of raw materials to a sintering temperature, which is about 1450 °C for modern cements. The aluminium oxide and iron oxide are present as a flux and contribute little to the strength. COST ESTIMATION Plant Capacity 250 Ton/Day LandBuilding (8000 sq.mt.) Rs. 4.92 Cr

solutions project report of clinker grinding mill unit

Clinker grinding unit of tpd Manufacturer Of High-end Mini clincker grinding unit project cost 100 tpd. Technology; Mini cement plant 100 TPD to 500 TPD or Clinker grinding unit This project is environmentally friendly can be started with in 23 month contents of Planning Commission There are 206 mini cement plants in operation,

sbmchina/sbm grinding mill process in cement.md at main

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Processes Free Full-Text Evaluation of the Quality of the Cement

2023年3月7日Completion of the process—The basic component of cement is clinker, and additional components (mine slag, and limestone) and are ground together with a certain amount of natural or industrial gypsum. By grinding all cement components in ball mills, the cement is obtained. 11.

clinker grinding unit project report sremachineries

clinker grinding unit project reportclinker grinding machine. clinker grinding unit project report Cement production is a large energy consumption Raw materials coal and clinker grinding process are three power consumption accounts for about 70 72 of the total power consumption of the cement plant so the key to reducing the power consumption of

CLINKER GRINDING UNIT PROCESS UNDERSTANDING

Clinker Grinding. Clinker and gypsum, being mixed together in predetermined proportions, are fed to the grinding mills. Chemical gypsum, if used instead of natural gypsum, needs to be dried either by natural sun drying or by mechanical drying, before it is used with cooled and dried clinker for inter grinding in mills.

(PDF) CONVENTIONAL CLINKER GRINDING -A NEW

2020年4月29日This model enables the prediction of the electrical power consumption in clinker grinding (cement production), which contributes significantly to the cement production cost. Furthermore, the above

AVAILABLE AND EMERGING TECHNOLOGIES FOR

Grinding of clinker, together with additions of approximately 5 percent gypsum to control the setting properties of the cement can be done in ball mills, ball mills in combination with roller presses, roller mills, or roller presses. While vertical roller mills are feasible, they have not found wide acceptance in the U.S. Coarse

Clinker Grinding Unit Great Wall

Therefore, Clinker Grinding Unit system has simple technology, low failure rate, high operation efficiency, compact allocation, construction area of 70% of ball mill, construction space of 50-60% of ball mill, and it can help enterprises to save land resources effectively. 3. With excellent environmental benefit, low noise, and low dust.

Radiotracer Investigation of Clinker Grinding Mills for

Fig. 1: Design of clinker grinding system; mill and separator Fig. 2: External view of Mill 4 (left) and mill 3 (right) at GHACEM machine design and/or choosing optimal operating and

CLINKER GRINDING UNIT PROCESS UNDERSTANDING

Clinker Grinding. Clinker and gypsum, being mixed together in predetermined proportions, are fed to the grinding mills. Chemical gypsum, if used instead of natural gypsum, needs to be dried either by natural sun drying or by mechanical drying, before it is used with cooled and dried clinker for inter grinding in mills.

mill/sbm clinker grinding project report malaysia.md at master mill

You've already forked mill 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long. 1 Commit. 1 Branch. 0 Tags mill / sbm clinker grinding projec...

sbmchina/sbm grinding mill process in cement.md at main

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Solutions Project Report Of Clinker Grinding Mill Unit

Solutions Project Report Of Clinker Grinding Mill Unit. Aug 18 2020 solutions project report of clinker grinding mill unit project report of grinding mill clinker grinding unit project report ement production is a large energy consumptionaw materials coal and clinker grinding process are three power consumption accounts for about 70 72 of

Project Report on cement grinding unit Manufacturing Plant,

Portland cement clinker is made by heating, in a kiln, a homogeneous mixture of raw materials to a sintering temperature, which is about 1450 °C for modern cements. The aluminium oxide and iron oxide are present as a flux and contribute little to the strength. COST ESTIMATION Plant Capacity 250 Ton/Day LandBuilding (8000 sq.mt.) Rs. 4.92 Cr

project report for 1000 tpd capacity clinker grinding unit

2014/02/14 project cost of 500 tpd clinker grinding unit in india 300 tpd cement factories for sale in south india La Mining Re: 300-500tpd small cement plant/cement factory for sale/cement clinker grinding the more like mini cement plant, clinker grinding unit, 200 tpd cement gr.

clinker grinding unit project report sremachineries

clinker grinding unit project reportclinker grinding machine. clinker grinding unit project report Cement production is a large energy consumption Raw materials coal and clinker grinding process are three power consumption accounts for about 70 72 of the total power consumption of the cement plant so the key to reducing the power consumption of

Processes Free Full-Text Evaluation of the Quality of the Cement

2023年3月7日Completion of the process—The basic component of cement is clinker, and additional components (mine slag, and limestone) and are ground together with a certain amount of natural or industrial gypsum. By grinding all cement components in ball mills, the cement is obtained. 11.

Breakthrough in Clinker Grinding Massachusetts Institute

2012年11月8日grinding seeks to reduce materials from roughly one meter cubes of blasted stone to a size where at least 80 percent of the raw material is less than 75 microns. Finish grinding of clinker and other cement ingredients reduces 25 mm clinker balls to particle sizes optimally ranging from 3 to 30 microns. The

project report on clinker grinding unit of india

The present plant is a clinker grinding unit. The project is not interlinked with any industry. The project falls under activity 3 (b ) and category "B". Due to inter state boundary this project will be considered at MoEFCC. The plant is a grinding unit solutions project report of clinker ball mill unit. Clinker Grinding Plant 30 Tpd