Professional Cement Clinker Fine Impact Mining Mill

Correlating common breakage modes with impact

2020年11月1日Impact loading tests were performed with a drop-weight tester on seven size fractions of the Portland cement clinker, and four size fractions of the chromite ore.

Cement clinker Wikipedia

OverviewComposition and preparationUsesClinker grinding aidsClinker minerals hydrationContribution to global warmingSee also

Cement clinker is a solid material produced in the manufacture of Portland cement as an intermediary product. Clinker occurs as lumps or nodules, usually 3 millimetres (0.12 in) to 25 millimetres (0.98 in) in diameter. It is produced by sintering (fusing together without melting to the point of liquefaction) limestone and aluminosilicate materials such as clay during the cement kiln stage.

Cement mill Wikipedia

OverviewHistoryMaterials groundTemperature controlBall MillsRoller millsHigh-pressure roll pressesCapacity of cement mills

A cement mill (or finish mill in North American usage ) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills. https://en.wikipedia/wiki/Concrete_grinder

(PDF) Correlating common breakage modes with impact

2020年2月19日This stone aims to show the presence of common breakage modes in impact breakage and ball milling of the cement clinker and chromite samples. For that

Clinker Production an overview ScienceDirect Topics

Assessing the environmental impact of conventional and ‘green’ cement production. G. Habert, in Eco-efficient Construction and Building Materials, 2014 Energy efficiency.

International Journal of Mining Science and Technology

Impact breakage Ball mill Self-similarity modes in impact breakage and ball milling of the cement clinker and chromite samples. For that purpose, national Journal of Mining

Use Cement Ball Mill Grinding Cement Clinker Cement

23 行According to the needs of different customers, there are two types of cement ball mill: open-flow mill and circular-flow mill. The φ3.8×13 cement ball mill with double-sliding structure solves the problem of the similar

CHAENG-Mining Equipment Suppliers

This cement equipment is mainly composed of cylinder, supporting device, supporting device with catch wheel, transmission device. The ball mill for clinker is an efficient tool

Some tests on the grinding of cement clinker with a

this mill will last much longer in the cement industry in vie of the constant demand for lower maintanance and higher capacity. The Huntington Mill ill grind between 18 to 30 barrels

Professional Cement Clinker Grinding Plant with Cement Ball Mill

Our products include Φ2.2 to 4.8m series slip type, bearing type and double slide shoe high-fine cement mills and rotary kilns, 1.7m and above vertical mills, pre-grinding crushing

Environmental Impact of Calcium Sulfoaluminate Cement

4 小时之Ordinary portland cement (OPC) manufacturing contributes to about 5–8% of the CO2 emissions globally and its consumption is expected to increase. Finding alternative to OPC is a global issue in the recent times. Calcium sulfoaluminate (CSA)-based binder is...

(PDF) Correlating common breakage modes with impact breakage

2020年2月19日This stone aims to show the presence of common breakage modes in impact breakage and ball milling of the cement clinker and chromite samples. For that purpose, narrow size fractions of the...

Cements Mine Mill Manufacturers, Exporters, Suppliers, Traders

Cements Mine Mill companies ☆ Find Cements Mine Mill manufacturers, suppliers, exporters, factories and trading agents. For Buyers. New Products; Machinery Other Machinery MiningMetallurgy Machinery Mining Machinery Mine Mill "cements" Cancel. Henan ZhengKuang Machinery Co.,Ltd.

An Insight into the Chemistry of Cement—A Review

2022年11月23日Cement forms a composite defined as mortar when mixed with water and fine aggregate (i.e., sand), whereas it forms concrete when Table 2 describes the approximate composition of the cement clinker . 3.2. Chemical Reactions Occurring during the Hydration Process Ed.; Gulf Professional Publishing: Dhahram, Saudi Arabia,

Use Cement Ball Mill Grinding Cement Clinker

According to the needs of different customers, there are two types of cement ball mill: open-flow mill and circular-flow mill. The φ3.8×13 cement ball mill with double-sliding structure solves the problem of the

Professional Cement Clinker Grinding Plant with Cement Ball Mill

Our products include Φ2.2 to 4.8m series slip type, bearing type and double slide shoe high-fine cement mills and rotary kilns, 1.7m and above vertical mills, pre-grinding crushing mills, bag filters, cyclones, garbage carbide and digesting furnaces, combined garbage burning and hot water boilers, together with iron ore ball mills, crushers

Ball Mill for Sale Mining and Cement Milling

1500t/d Continuous Ball Mill for Copper Mining in Pakistan. Production capacity: 1500t/d Processed material: Copper ore Input size: ≤25mm Equipment: 98-386t/h copper ball mill, jaw crusher, cone crusher,

Silica Sand Slag Rod Ball Grinding Mill Cement Clinker Grinding

Quality Silica Sand Slag Rod Ball Grinding Mill Cement Clinker Grinding Ball Mill Production Line find quality Ore Beneficiation Machine, Mine MillOre Beneficiation Machine from Zhengzhou VANGUARD Machinery Technology Co., Ltd. of China Suppliers

Cement plant design under EPC contract esfccompany

Our team offers financing and engineering design for cement plants around the world, helping companies implement innovative technical solutions

42 5r cement clinker for sale, 42 5r cement clinker of Professional

Quality 42 5r cement clinker products list 42 5r cement clinker Provided by ManufacturersWholesalers from China. Sign In Join Free My infospaceinc: For Buyers. Henan Zhengzhou Mining Machinery CO.Ltd. Address: 15th Fl, Bldg No.13, National University Science Park(East), No.279, West 3# Ring Rd, Zhengzhou, China.

An industrial comparative study of cement clinker grinding

This stone is concerned with a comparative analysis of modern cement grinding systems, namely, combined grinding (Comflex®), high-pressure roll mill (HPRM) grinding, and horizontal roller mill (Horomill®) grinding. Cement production trials were run with these grinding systems in the same cement plant by using the same clinker/gypsum feed to

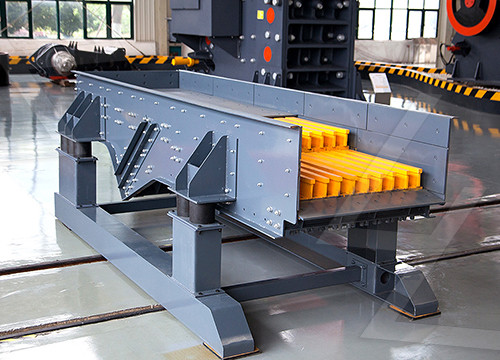

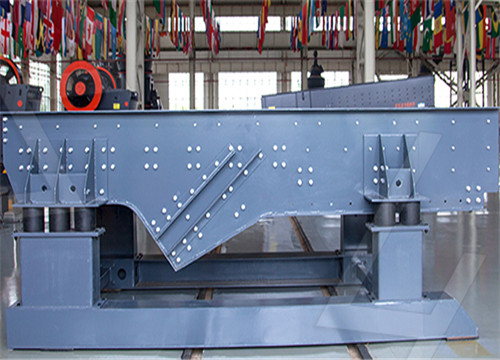

Mining Iron Ore Rollers Crushing Machine Price,Coal Double Toothed Mill

Application: Limestone,coal,coke,clinker, granite, basalt, cement, brick, tile,building material etc Advantage 1.The rollers is wear-resisting chromium molybdenum copper alloy with long service. 2.The gap between the rollers is adjustable, so that the output size and capacity will be changed accordingly. 3.This crusher is equipped with

Physicochemical characterization of particulate matter in a cement

3.2.3 Cement mill Clinker (>50%) and limestone 3K 2 SO 4 Na 2 SO 4, and K 2 SO 4 2CaSO 4, which may get incorporated in the clinker. 45 These compounds can also leave the cement kiln as fine PM or form coatings on kiln surfaces. A bypass is often installed for reducing the intensity of the chloride cycle with the aim of avoiding kiln

Clinker quality depends on raw material composition. Advancing Mining

2014年1月14日It is used primarily to make concrete, mortar, and grout. Portland cement manufacturing begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiln.

Environmental Impact of Calcium Sulfoaluminate Cement

4 小时之Ordinary portland cement (OPC) manufacturing contributes to about 5–8% of the CO2 emissions globally and its consumption is expected to increase. Finding alternative to OPC is a global issue in the recent times. Calcium sulfoaluminate (CSA)-based binder is...

(PDF) Correlating common breakage modes with impact breakage

2020年2月19日This stone aims to show the presence of common breakage modes in impact breakage and ball milling of the cement clinker and chromite samples. For that purpose, narrow size fractions of the...

Cements Mine Mill Manufacturers, Exporters, Suppliers, Traders

Cements Mine Mill companies ☆ Find Cements Mine Mill manufacturers, suppliers, exporters, factories and trading agents. For Buyers. New Products; Machinery Other Machinery MiningMetallurgy Machinery Mining Machinery Mine Mill "cements" Cancel. Henan ZhengKuang Machinery Co.,Ltd.

An Insight into the Chemistry of Cement—A Review

2022年11月23日Cement forms a composite defined as mortar when mixed with water and fine aggregate (i.e., sand), whereas it forms concrete when Table 2 describes the approximate composition of the cement clinker . 3.2. Chemical Reactions Occurring during the Hydration Process Ed.; Gulf Professional Publishing: Dhahram, Saudi Arabia,

Use Cement Ball Mill Grinding Cement Clinker

According to the needs of different customers, there are two types of cement ball mill: open-flow mill and circular-flow mill. The φ3.8×13 cement ball mill with double-sliding structure solves the problem of the

Professional Cement Clinker Grinding Plant with Cement Ball Mill

Our products include Φ2.2 to 4.8m series slip type, bearing type and double slide shoe high-fine cement mills and rotary kilns, 1.7m and above vertical mills, pre-grinding crushing mills, bag filters, cyclones, garbage carbide and digesting furnaces, combined garbage burning and hot water boilers, together with iron ore ball mills, crushers

Ball Mill for Sale Mining and Cement Milling

1500t/d Continuous Ball Mill for Copper Mining in Pakistan Production capacity: 1500t/d Processed material: Copper ore Input size: ≤25mm Equipment: 98-386t/h copper ball mill, jaw crusher, cone crusher,

Silica Sand Slag Rod Ball Grinding Mill Cement Clinker Grinding

Quality Silica Sand Slag Rod Ball Grinding Mill Cement Clinker Grinding Ball Mill Production Line find quality Ore Beneficiation Machine, Mine MillOre Beneficiation Machine from Zhengzhou VANGUARD Machinery Technology Co., Ltd. of China Suppliers

Cement plant design under EPC contract esfccompany

Our team offers financing and engineering design for cement plants around the world, helping companies implement innovative technical solutions

42 5r cement clinker for sale, 42 5r cement clinker of Professional

Quality 42 5r cement clinker products list 42 5r cement clinker Provided by ManufacturersWholesalers from China. Sign In Join Free My infospaceinc: For Buyers. Henan Zhengzhou Mining Machinery CO.Ltd. Address: 15th Fl, Bldg No.13, National University Science Park(East), No.279, West 3# Ring Rd, Zhengzhou, China.

Cement Clinker Quality Control AGICO Cement Plant

The following are several important factors affecting the cement clinker quality. In the process of clinker production, strict control of these factors can ensure the production of high-quality, high-yield clinker. 1. Lime Saturation Factor. The lime saturation factor (LSF) is a ratio of CaO to other oxides, it is used to control the proportion

An industrial comparative study of cement clinker grinding

This stone is concerned with a comparative analysis of modern cement grinding systems, namely, combined grinding (Comflex®), high-pressure roll mill (HPRM) grinding, and horizontal roller mill (Horomill®) grinding. Cement production trials were run with these grinding systems in the same cement plant by using the same clinker/gypsum feed to

Physicochemical characterization of particulate matter in a cement

3.2.3 Cement mill Clinker (>50%) and limestone 3K 2 SO 4 Na 2 SO 4, and K 2 SO 4 2CaSO 4, which may get incorporated in the clinker. 45 These compounds can also leave the cement kiln as fine PM or form coatings on kiln surfaces. A bypass is often installed for reducing the intensity of the chloride cycle with the aim of avoiding kiln

I03 cement June 2010 GS-gct IEA-ETSAP

For example, Portland cement consists of 95% clinker, whereas Portland-slag cement contains less clinker but contains blast furnace slag in the range of 6 to 35%. All cement types also contain up to 5% of calcium sulphates. In 2005, the most common cement types for EU-25 were Portland Composite cement (58,6%) and Portland cement (27,4%),