Roller Mill Used For Cement Manufacturing Process

Review on vertical roller mill in cement industryits

2021年1月1日Ball mills have been used as the main grinding tool for cement production for over 100 years. Although easy to operate and competitive compared to other

What Equipment is Used for Cement Manufacturing?

For North American cement manufacturing plants, vertical roller mills commonly handle the raw materials that will become cement, often with a throughput of 150-750 tons per

Vertical Roller Mill Operation in Cement Plant

The Material Layer of The MillThe Vibration of The MillThe Grinding Pressure of The MillThe Gas Temperature at The Discharging PortThe Air Volume in The MillThe Hot Gas from The Kiln

The strong vibration of the mill body may cause mechanical failure and has a bad effect on the product quality. There are many factors that may make the mill body vibrate, including the grinding pressure, material layer thickness, air volume and temperature, accumulator pressure, wear condition of the roller and the grinding plate, etc.

Ball MillRoller Press for Cement Grinding Process AGICO

Today we will introduce three mainstream ball mill + roller press cement grinding processes that are often adopted in cement manufacturing plants and cement grinding

Cement Manufacturing Process Phases Flow Chart

2012年8月30日Cement Manufacturing Process Phase 1: Raw Material Extraction. Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone

Modern Processing Techniques to minimize cost in

Vertical Roller Mill (VRM) The power used for the actual grinding process while grinding raw materials, depends mainly on the hardness of raw materials and the type of mill

Cement Production Process Cement Manufacturing Process

2020年8月25日In general, a full cement production process includes the stone crushing, raw mill process, clinker process, and cement grinding process, cement packing

Cement Manufacturing Process: 6 StepsTo Make Cement

2020年1月27日The grinding process is carried out in a closed system, which is equipped with an cement separator to separate cement particles according to size, and materials that are not completely finely ground are

AVAILABLE AND EMERGING TECHNOLOGIES FOR

be done in ball mills, ball mills in combination with roller presses, roller mills, or roller presses. While vertical roller mills are feasible, they have not found wide acceptance in

Vertical Roller Mills

We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades. The vertical roller mill is well known in the cement and power plant industries as the preferred mill for

Review on vertical roller mill in cement industryits

2021年1月1日Ball mills have been used as the main grinding tool for cement production for over 100 years. Although easy to operate and competitive compared to other technologies, the poor efficiency of ball mills has been one of the main reasons for research and development of more efficient grinding processes in recent years.

11.6 Portland Cement Manufacturing US EPA

1971年8月17日11.6 Portland Cement Manufacturing 11.6.1 Process Description1-7 Portland cement is a fine powder, gray or white in color, that consists of a mixture of accomplished during grinding in ball-and-tube mills or roller mills. While thermal energy for drying can be supplied by exhaust gases from separate, direct-fired coal, oil, or gas

What Equipment is Used for Cement Manufacturing? Prater

For North American cement manufacturing plants, vertical roller mills commonly handle the raw materials that will become cement, often with a throughput of 150-750 tons per hour. Bulk cement manufacturing equipment like rotary feeders help transfer raw materials at different points during production.

Vertical Roller Mill Operation in Cement Plant

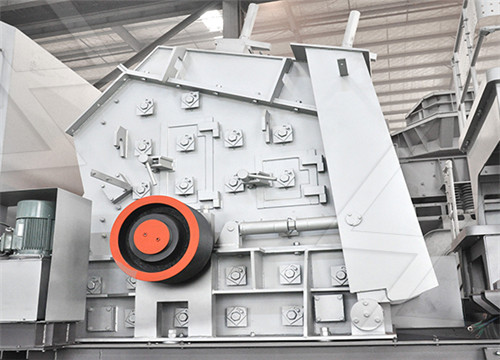

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process.In recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc.. The

What equipment is used in the cement process?

2023年2月14日Equipment used in the cement process includes kilns, crushers, grinders, and blenders. Kilns are used to create the heat necessary to turn the raw materials into clinker. Crushers are then...

3 Necessary Cement Milling Comparison Ball Mill, Vertical Roller Mill

2020年11月5日Vertical roller mill, also called cement vertical mill, it grinds raw materials by the movement between grinding roller, millstone and grinding device. In general the grinding efficiency of vertical roller mill is 80% as much power as cement ball mill, reduce about 30% power consumption. vertical cement mill Advantages

What are the parts of a mill in a cement plant?

2023年3月6日A cement mill is an important component of the cement manufacturing process in a cement plant. It is responsible for grinding clinker, gypsum, and other materials into a fine powder that is used

MVR roller mill Indian Cement Review

2021年10月14日MVR roller mills are used for grinding cement clinker, granulated blast-furnace slag and Pozzolana. Bulk materials vary considerably in terms of grindability and abrasiveness. The capacities of cement production lines too vary within wide limits to suit individual requirements.

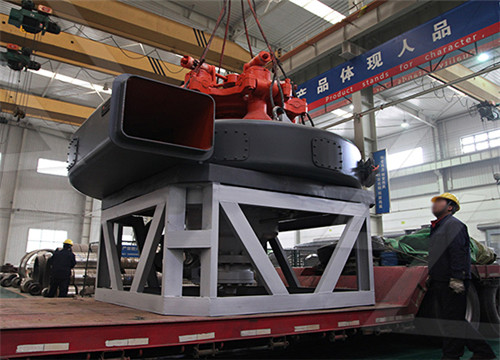

Vertical Roller Grinding Machine Roller Assembly

Millstone is one of the key parts of vertical mill, which is mainly composed of resistance ring, liner and base.Optimize the design of the grinding disc casting process to overcome the deficiencies of the previous structure, make the grinding disc base uniformly stressed, increase the bite angle between the grinding disc grinding rollers, and avoid brush

Modern Processing Techniques to minimize cost in Cement

Vertical Roller Mill (VRM) The power used for the actual grinding process while grinding raw materials, depends mainly on the hardness of raw materials and the type of mill used, i.e. ball mill or vertical roller mill. Typically, the motor of the ball mill consumes about 14 15 kWh/ ton of raw mix whereas the VRM motor

Roller Press + Ball mill circuit for Cement production Higher

Roller Press + Ball mill circuit for Cement production Higher grinding plant process availability.Acceptability of Roller press combination with Ball mill

Cement Mill for Sale Buy Cement Ball MillVertical Roller Mill

Cement mills are the milling machines used in cement plants to grind hard clinker into fine cement powders. Cement ball mill and vertical roller mill are two most widely used cement mills in today’s cement grinding plants and

Do You Really Know Raymond Roller Mill Raymond Mill AGICO Cement

Raymond roller mill, also known as Raymond mill, is a commonly used grinding mill in industrial production, can be used for processing more than 280 kinds of materials. It has the characteristics of stable performance, simple structure, convenient operation, long service life and high output. About its origin, I believe many people are holding

Vertical Roller Mills

We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades. The vertical roller mill is well known in the cement and power plant industries as the preferred mill for

What Equipment is Used for Cement Manufacturing? Prater

For North American cement manufacturing plants, vertical roller mills commonly handle the raw materials that will become cement, often with a throughput of 150-750 tons per hour. Bulk cement manufacturing equipment like rotary feeders help transfer raw materials at different points during production.

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process.In recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc.. The

What equipment is used in the cement process?

2023年2月14日Equipment used in the cement process includes kilns, crushers, grinders, and blenders. Kilns are used to create the heat necessary to turn the raw materials into clinker. Crushers are then...

3 Necessary Cement Milling Comparison Ball Mill, Vertical Roller Mill

2020年11月5日Vertical roller mill, also called cement vertical mill, it grinds raw materials by the movement between grinding roller, millstone and grinding device. In general the grinding efficiency of vertical roller mill is 80% as much power as cement ball mill, reduce about 30% power consumption. vertical cement mill Advantages

Roller Press + Ball mill circuit for Cement production Higher

2020年8月22日Roller Press + Ball mill circuit for Cement production Higher grinding plant process availability. Acceptability of Roller press combination with Ball mill circuit is

MVR roller mill Indian Cement Review

2021年10月14日MVR roller mills are used for grinding cement clinker, granulated blast-furnace slag and Pozzolana. Bulk materials vary considerably in terms of grindability and abrasiveness. The capacities of cement production lines too vary within wide limits to suit individual requirements.

What are the parts of a mill in a cement plant?

2023年3月6日A cement mill is an important component of the cement manufacturing process in a cement plant. It is responsible for grinding clinker, gypsum, and other materials into a fine powder that is used

Do You Really Know Raymond Roller Mill Raymond Mill AGICO Cement

Raymond roller mill, also known as Raymond mill, is a commonly used grinding mill in industrial production, can be used for processing more than 280 kinds of materials. It has the characteristics of stable performance, simple structure, convenient operation, long service life and high output.

Vertical Roller Grinding Machine Roller Assembly

Millstone is one of the key parts of vertical mill, which is mainly composed of resistance ring, liner and base.Optimize the design of the grinding disc casting process to overcome the deficiencies of the previous structure, make the grinding disc base uniformly stressed, increase the bite angle between the grinding disc grinding rollers, and avoid brush

Cement Manufacturing Process Flow Chart

The process of making cement is described in and dried in storage basins. The two materials are mixed in the correct proportion and ground in a tube mill (This mixture is known as slurry) and stirred in a correcting basin. It is then stored in a storage tank. a heated roller, and finally wound on to a bobbin. Process of making RAYON

BASIC CEMENT PLANT LAYOUT Process Cement Forum The Cement

2020年7月4日The mills used for coal grinding and drying are either trumbling mills (tube mills) or roller mills. 14 Cement Mill and Bag House . Clinker, along with additives, is ground in a cement mill. The output of a cement mill is the final product viz. Cement. In a cement mill, there is a cylindrical shell lying horizontal which contains metallic balls

Nelson Machinery International Sellers of Second-Hand Cement

Specializing in the sale of second hand cement plant equipment, and complete used cement plants. In addition to used and new surplus Cement Plant Equipment (rotary kilns, ball mills, vertical roller mills), NMI deals in many other types of machinery, including used equipment for Bulk Material Handling, Crushing, Grinding, Industrial Mineral Processing,

Rolling Mill Roller Table Customizable Roller Table Customizable

Its weight accounts for about 40% of the total weight of the entire steel rolling workshop. It is the most used equipment in the steel rolling workshop. The rolling stock enters and exits the heating furnace, reciprocating rolling on the rolling mill, and transporting to the finishing process after rolling are all completed by the roller table.