New Type Made In Mine Mineral Flotation Cell

Review on advances in mineral processing technologies

2022年4月1日Flotation is a physio-chemical process that utilises particles' physical attachment to bubbles to separate minerals by floating them to the surface of flotation cells. Hydrophobic (or water repelling) surfaces can attach to bubbles and be floated,

进一步探索

(PDF) Overview of Mineral Processing Methods Researc(PDF) Mineral Processing Technology ResearchGate(PDF) Mineral Processing Technology An Introduction to (PDF) Introduction to Mineral Processing Academia.eduWhat are the Four Types of Mineral Processing? Sepro 根据热度为您推荐•反馈

unveils upgrades to flotation cells Mining Magazine

2022年2月28日Danish engineering firm has unveiled upgrades to flotation technologies at the Mine Exchange 2022 SME annual conference. The company has

进一步探索

’s SuperCell™ 600 series revolutionizes flotationWEMCO Flotation Cell 293475 Bid on Equipment根据热度为您推荐•反馈

Froth flotation Wikipedia

OverviewHistoryIndustriesPrinciple of operationScience of flotationFlotation equipmentChemicals of flotationSpecific applications

Flotation process are described in ancient Greek and Persian literature. During the late 19th century, the process basics were discovered through a slow evolutionary phase. During the first decade of the 20th century, a more rapid investigation of oils, froths, and agitation led to proven work-place applications, especially at Broken Hill, Australia, that brought the technological innovation k

SELECTION OF MECHANICAL FLOTATION EQUIPMENT

flotation cell rotor. Traditionally flotation plant design blower selection and control has been based on using an oversized positive displacement blower, or an industrial fan, with

Mining Chemicals for Lithium Mineral Flotation

Our CYQUEST® dispersants are synthetic anionic polymers that feature a low-to-high molecular weight. These mining reagents for lithium processing optimize collector performance by modifying pulp rheology to enhance

New flotation cell with mechanism for the minerals

2021年1月26日The new DELKOR BQR MAXGen flotation cell also boasts more eloquent features addressing many practical challenges when improving installation, maintenance and operation of flotation circuits,

Flotation: Advantage Circular Cells Mining Technology

Flotation: Advantage Circular Cells. From its beginnings in the first decade of this century, flotation has gradually moved to a predominant role in mineral separation. Alain

Rougher Flotation Cells Mining and Mineral

2021年8月16日The aimed minerals will be concentrating in the froth. These concentration froth will be sent into the cleaning flotation cells for getting the concentration with high grade of aimed minerals. Rougher

Mining Aggregates

The flotation cells at the customer’s mines were being damaged by the materials processed in these tanks. Flotation cells are contained units that are used to perform froth flotation on a slurry to extract valuable

Laboratory Flotation Cells Mining and Mineral Processing

Laboratory flotation cells are mainly for stirring, scrubbing, separating and concentrating small quantities of ore samples. ZJH laboratory flotation cells could be applied for the

Review on advances in mineral processing technologies suitable

2022年4月1日Mineral liberation can be achieved using stirred milling, which breaks up particles and removes hydrophilic surface that can prevent particle flotation. Particle separation based on size can be achieved using semi-inverted cyclones and hybrid classification technologies.

Minerals Free Full-Text The Effect of Conditioning on the Flotation

2017年7月20日Flotation tests were conducted in a XFG type mechanical agitation flotation machine equipped with a flotation cell of 40 mL. For each test, 2.0 g of minerals was mixed and dispersed in 40 mL of distilled water in the flotation cell.

Replacement of old flotation cells in the flotation

2021年1月1日Abstract. Russian made FPM-GMO-1.6 flotation machines were previously installed for primary stage flotation concentration of lead and zinc minerals in Lece flotation plant. For cleaning stage FMR

Minerals Free Full-Text The Challenges and Prospects of MDPI

2022年5月6日Flotation is a common mineral processing method used to upgrade copper sulfide ores; in this method, copper sulfide mineral particles are concentrated in froth, and associated gangue minerals are separated as tailings.

Selective flotation separation of cassiterite and calcite through

3 小时之The flotation was followed by the filtration to remove water. The mineral particles left in the cell were collected to afford the flotation tailing. The flotation concentrate and tailing were dried and weighted. The recovery was calculated based on the weight distribution of these two products using the following equation.

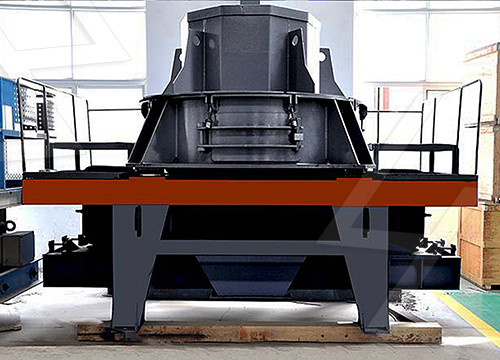

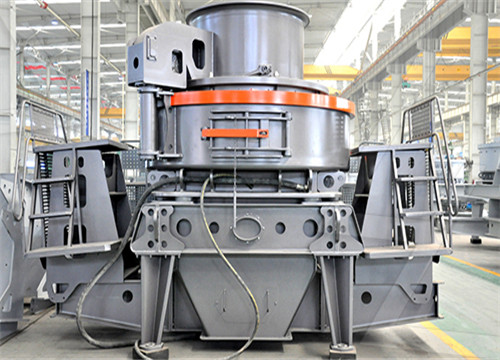

Clf Coarse Particle Mining Flotation Cell For Mineral Ore Process

CLF Coarse Particle Flotation Machine Mining Flotation Cell for Mineral Ore Process . It has the following feature: adopting new-type impeller-stator system and installed with cell with forced circulation passage consisting of false bottom and grid plate, a whole new ore pulp circulation mode, a stable separation area and foam layer are

Laboratory Flotation Cells Mining and Mineral Processing

Laboratory flotation cells are mainly for stirring, scrubbing, separating and concentrating small quantities of ore samples. ZJH laboratory flotation cells could be applied for the industies of geology, metallurgy, miningmineral beneficiation, coal, gold, chemical engineering. Our laboratory flotation machine also for the laboratories of

mill/sbm mining new type mineral flotation cell.md at main

Contribute to crush2022/mill development by creating an account on GitHub.

Denver Flotation Cell Machine for Metal Separator Laboratory Flotation

Type: Flotation Separator Voltage: 220V Weight: 135kg Certification: ISO9001:2008 Energy Saving: Energy Saving Warranty: 1 Year

Xinhai Mining Appears at PDAC Global Mining Conference in

From March 5th to 8th, the 91st Annual Conference of ProspectorsDevelopers Association of Canada (PDAC) was officially held in Toronto. Xinhai Mining made a wonderful appearance at the exhibition site. Chairman Zhang Yunlong was invited to attend the exhibition, sharing the latest industry development trends and discussing global

China Mine Machine Manufacturer, Flotation

Flotation Machine, Flotation Cell, Ball Mill manufacturer / supplier in China, offering Solid-Liquid Separation Machine for Mineral Processing Mining Filter Press at Good Price, Mining Pulp Separator Mining Classifier

Flotation cells SKF SKF

Increase uptime and ease the maintenance burden. Separating minerals in a froth flotation cell has a particularly corrosive effect on a slowly rotating rake and its components. Mixtures of slurry, surfactant, water, air and froth can quickly lead to failed seals and bearings. Which, of course, means costly unplanned downtime and lost productivity.

Small Flotation XFDIII Single Cell Lab Flotation JXSC Machine

The single-cell flotation machine (mine-use single-cell flotation machine) is driven by the triangular transmission of the motor to rotate the impeller, which generates centrifugal action to form a negative pressure. Mineralized foam, so that minerals adhere to the foam, float to the surface of the slurry and then form mineralized foam.

Enhancing flotation cells for increased sustainable production

2021年11月19日The latest addition to Metso Outotec’s flotation equipment range is the Concorde Cell™, which sets a new benchmark in high intensity pneumatic flotation by recovering unachievable fine and

Review on advances in mineral processing technologies suitable

2022年4月1日Mineral liberation can be achieved using stirred milling, which breaks up particles and removes hydrophilic surface that can prevent particle flotation. Particle separation based on size can be achieved using semi-inverted cyclones and hybrid classification technologies.

Replacement of old flotation cells in the flotation

2021年1月1日Currently, 8 new RCS-5 cells for coarse and scavengel flotation of lead minerals and 4 RCS-3 cells for cleaning of coarse lead mineral concentrate are working on the lead flotation...

Copper minerals flotation in flotation plant of the "Rudnik" mine

2019年1月1日The Sarcheshmeh copper mine is a significant copper and molybdenum producer. Sampling of the Sarcheshmeh flotation circuit (in a six-month period) showed that a large share of waste of...

Selective flotation separation of cassiterite and calcite through

3 小时之The flotation was followed by the filtration to remove water. The mineral particles left in the cell were collected to afford the flotation tailing. The flotation concentrate and tailing were dried and weighted. The recovery was calculated based on the weight distribution of these two products using the following equation.

Minerals Free Full-Text The Depressing Effect of Kaolinite on

2020年6月26日Molybdenum is a strategic metal which is commonly found associated with copper in porphyry copper deposits, and molybdenite (MoS 2) is the main molybdenum-containing mineral, which is characterized by its natural hydrophobicity, thus it readily floats together with copper sulfides.

Clf Coarse Particle Mining Flotation Cell For Mineral Ore Process

CLF Coarse Particle Flotation Machine Mining Flotation Cell for Mineral Ore Process . It has the following feature: adopting new-type impeller-stator system and installed with cell with forced circulation passage consisting of false bottom and grid plate, a whole new ore pulp circulation mode, a stable separation area and foam layer are

China Mine Machine Manufacturer, Flotation

Flotation Machine, Flotation Cell, Ball Mill manufacturer / supplier in China, offering Solid-Liquid Separation Machine for Mineral Processing Mining Filter Press at Good Price, Mining Pulp Separator Mining Classifier

Laboratory Flotation Cells Mining and Mineral Processing

Laboratory flotation cells are mainly for stirring, scrubbing, separating and concentrating small quantities of ore samples. ZJH laboratory flotation cells could be applied for the industies of geology, metallurgy, miningmineral beneficiation, coal, gold, chemical engineering. Our laboratory flotation machine also for the laboratories of

Denver Flotation Cell Machine for Metal Separator Laboratory Flotation

Type: Flotation Separator Voltage: 220V Weight: 135kg Certification: ISO9001:2008 Energy Saving: Energy Saving Warranty: 1 Year

Xinhai Mining Appears at PDAC Global Mining Conference in

From March 5th to 8th, the 91st Annual Conference of ProspectorsDevelopers Association of Canada (PDAC) was officially held in Toronto. Xinhai Mining made a wonderful appearance at the exhibition site. Chairman Zhang Yunlong was invited to attend the exhibition, sharing the latest industry development trends and discussing global

Enhancing flotation cells for increased sustainable production

2021年11月19日The latest addition to Metso Outotec’s flotation equipment range is the Concorde Cell™, which sets a new benchmark in high intensity pneumatic flotation by recovering unachievable fine and

Flotation cells SKF SKF

Increase uptime and ease the maintenance burden. Separating minerals in a froth flotation cell has a particularly corrosive effect on a slowly rotating rake and its components. Mixtures of slurry, surfactant, water, air and froth can quickly lead to failed seals and bearings. Which, of course, means costly unplanned downtime and lost productivity.

Small Flotation XFDIII Single Cell Lab Flotation JXSC Machine

The single-cell flotation machine (mine-use single-cell flotation machine) is driven by the triangular transmission of the motor to rotate the impeller, which generates centrifugal action to form a negative pressure. Mineralized foam, so that minerals adhere to the foam, float to the surface of the slurry and then form mineralized foam.

Mineral Froth Flotation Machine (flotation cell) for All Kinds of

Company Introduction: Xperience, its products and services are exported to more than 60 countries and regions. Sinonine has been looking for the best mode of development to achieve win-win situation with customers at designing and building mineral processing plant since its establishment.