Oem Jaw Crusher For Rock With Patent Jaw Plate

Jaw crusher parts Metso Outotec

根据热度为您推荐•反馈

Jaw Crusher Crushing Plant Hard Rock Mining

根据热度为您推荐•反馈

Jaw Crusher Wear Parts Columbia Steel Cast Products

Columbia Steel offers more jaw crusher plate styles than any manufacturer in the industry. Each of these designs has been developed for a

Jaw Crusher Eastman Rock Crusher

10-350mm Jaw crusher is a compression style rock crusher, useful in crushing the medium-hard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit. Applications mining,

Jaw-type rock crusher with toggle plate tension bar

Accordingly, the present invention is a system and method including a jaw crusher which utilizes at least one of the following: an electronically controlled and/or automatically

Jaw Crusher Liner Plate DesignProfile Shapes

2015年7月22日These non-choking jaw plates have been developed in two styles, reversible and non-reversible. The advantage of the reversible design has been outlined in connection with its application to the gyratory

Jaw Crusher Plates Wear Parts For Industry Qiming

2017年3月1日As the genuine OEM parts supplier for all kinds of crusher jaw plates, Qiming Casting stock and supply the entire range of products to suit the entire jaw

Jaw Crusher Toggle Plates vs. Hydraulic Toggle Relief

2021年5月17日The Eagle Crusher hydraulic toggle relief system is available to be equipped onto any Eagle Crusher jaw crushers and will reduce unexpected downtime, decrease unnecessary replacement costs,

Jaw Plate For Sale We Source Crusher Jaw Plates Northern

Jaw plates to suit crushers, Extec, Finlay and Fintec rock crushers. Northern Crusher Spares stock a wide range of jaw plate parts and replacements. We can also

CJ613 Single-Toggle Jaw Crusher With A Heavy Duty

Welded frame ensures equal strength in all directions, and excellent durability. Deep symmetrical crushing chamber and optimized nip angle maximizes size reduction and production capacity. Wide intake opening offers possibility to handle larger feeds. Technical data. Weight. 46,600 kg (103,000 lb) Feed opening. 1,300 x 1,130 mm (51 x 45 in.)

Jaw crushers, Stationary Jaw crusher series — SRP

Jaw crushers come with everything you need for plug-and-play primary crushing operations. Each jaw crusher comes with feed hopper, feed hopper interface, drive and subframe with v-belt guard and motor bracket, our unique guarding retraction arrangement and toggle plate stop.

® C160™ jaw crusher Metso Outotec

The tight nip angle in the middle of the cavity ensures that the processed material is quickly passed to the bottom of the cavity where the crusher’s long stroke finishes the job. Like all ® C Series™ jaw crushers the ® C160™ jaw crusher is built out of premium components. The main frame structure is based on unique

Industrial Solutions Jaw crushers ThyssenKrupp

Solutions has in its range two types of jaw crusher, which differ in the kinematics of Average throughput rate of single-toggle jaw crusher, hard-rock version, tolerance ± 10% 100 150 swing jaw moves forward. Serrated jaw plates enhance the crushing process. When the 200 250 300 350 400 1,600 1,400 1,200 1,000 800 600 400 200

Jaw Crusher Crushing Plant Hard Rock Mining Equipment DOVE

DOVE Jaw Crushers are ideal rock crusher machines, highly efficient and economical for handling Primary and Secondary stone crushing applications of various ores and bulk materials with compressive strength below 320 MPa.DOVE Crushers are supplied in Stationary complex plant configuration, or in Portable and Mobile configuration..

USB2 Jaw-type rock crusher with toggle plate Google Patents

It is an object of the present invention to provide a system and method for adjusting the output material size setting and maintaining the tension between a pitman and a toggle plate of a...

Jaw Rock Crusher Supplies By Trusted Manufacturer AGICO

The rock reduced by jaw crusher is ready for impact crusher and cone crusher to do the medium and fine crushing. Jaw crusher is currently the most common crushers for sale in the world. Equipped with high-manganese-steel jaw plates, it can crush ores, rocks, steel slag, and other hard materials. It can be used in cement plants, quarries, stone

Jaw Plate For Sale We Source Crusher Jaw Plates Northern Crusher

A jaw crusher is one of the main type of crushers used in mining operations, quarries and ore processing plants. A jaw crusher reduces the size of large rocks and ore through compression. The rock remains in the jaws of the crushing machine until it is small enough to pass through the gap towards the bottom of the jaws. Showing 1–12 of 26 results

Jaw Plate Casteel Foundry

Jaw Crusher Wear Parts: Item Names: Jaw Plate s ,Stationary Jaw Tooth, Movable Jaw Die Fixed Jaw, Swing Jaw Plate ,Jaw Fixed, Jaw Moveable,Cheek Plate,Side Plate Casting Material: Austenstic Manganese Steel (Mn14, M14Cr2, Mn18Cr2, Mn22Cr2)

What is High Manganese Steel Factory Crusher Plate Casting Process Jaw

What is High Manganese Steel Factory Crusher Plate Casting Process Jaw Crusher Parts Jaw Plates, casting manufacturerssuppliers on Video Channel of Made-in-China.

USB2 Jaw crusher Google Patents

A jaw crusher includes a crushing chamber between a fixed jaw and a swing jaw. The jaw crusher also includes an eccentric drive which supports the first end of the swing jaw. The...

Jaw Crusher Plates Wear Parts For Industry Qiming Casting

2017年3月1日Jaw Plates Jaw Plates As the genuine OEM parts supplier for all kinds of crusher jaw plates, Qiming Casting stock and supply the entire range of products to suit the entire jaw crusher range across all jaw crushing applications.

Manganese Casting Symons Telsmith Jaw Crusher Parts

Manganese Casting Symons Telsmith Jaw Crusher Parts Fixed / Swing Jaw Plate, Find Details and Price about Jaw Plate Swing Jaw Plate from Manganese Casting Symons Telsmith Jaw Crusher Parts Fixed / Swing Jaw Plate Jiangsu Boda Machinery Co., Ltd.

Jaw Crushers MEKA CrushingScreening Plants

Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement. There are also primary and secondary types of these crushers. Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds

CJ613 Single-Toggle Jaw Crusher With A Heavy Duty

Welded frame ensures equal strength in all directions, and excellent durability. Deep symmetrical crushing chamber and optimized nip angle maximizes size reduction and production capacity. Wide intake opening offers possibility to handle larger feeds. Technical data. Weight. 46,600 kg (103,000 lb) Feed opening. 1,300 x 1,130 mm (51 x 45 in.)

® C160™ jaw crusher Metso Outotec

The tight nip angle in the middle of the cavity ensures that the processed material is quickly passed to the bottom of the cavity where the crusher’s long stroke finishes the job. Like all ® C Series™ jaw crushers the ® C160™ jaw crusher is built out of premium components. The main frame structure is based on unique

Industrial Solutions Jaw crushers ThyssenKrupp

Solutions has in its range two types of jaw crusher, which differ in the kinematics of Average throughput rate of single-toggle jaw crusher, hard-rock version, tolerance ± 10% 100 150 swing jaw moves forward. Serrated jaw plates enhance the crushing process. When the 200 250 300 350 400 1,600 1,400 1,200 1,000 800 600 400 200

Jaw Crusher Crushing Plant Hard Rock Mining

DOVE JAW CRUSHER FEATURES: High tonnage capacity of up to 1,000 Tons/ Hour, and low operating cost. Designed for toughest rock material, with compressive strength of up to 320 MPa. Supplied for Primary coarse

USB2 Jaw-type rock crusher with toggle plate Google Patents

It is an object of the present invention to provide a system and method for adjusting the output material size setting and maintaining the tension between a pitman and a toggle plate of a...

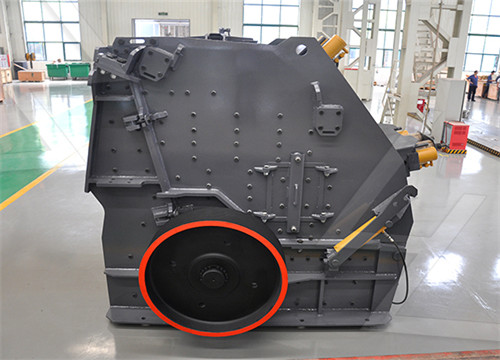

Rock Crusher Wear Parts: Blow Bars, Wear Liners, Jaw

Horizontal shaft impact (HSI) crusher replacement wear parts. We supply wear parts used in Horizontal Shaft Impact crushers. We specialize in many blow bars for different brands of HSI crushers. The blow bars are

Jaw Plate For Sale We Source Crusher Jaw Plates Northern Crusher

A jaw crusher is one of the main type of crushers used in mining operations, quarries and ore processing plants. A jaw crusher reduces the size of large rocks and ore through compression. The rock remains in the jaws of the crushing machine until it is small enough to pass through the gap towards the bottom of the jaws. Showing 1–12 of 26 results

Jaw Plate Casteel Foundry

Janpanese Jaw Crusher Parts: Item Names: Jaw Plate s ,Stationary Jaw Tooth, Movable Jaw Die Fixed Jaw, Swing Jaw Plate ,Jaw Fixed, Jaw Moveable,Cheek Plate,Side Plate Casting Material: Austenstic Manganese Steel (Mn14, M14Cr2, Mn18Cr2, Mn22 Kue-Ken Jaw Plates 2021-09-14

Manganese Casting Symons Telsmith Jaw Crusher Parts

Manganese Casting Symons Telsmith Jaw Crusher Parts Fixed / Swing Jaw Plate, Find Details and Price about Jaw Plate Swing Jaw Plate from Manganese Casting Symons Telsmith Jaw Crusher Parts Fixed / Swing Jaw Plate Jiangsu Boda Machinery Co., Ltd.

What is High Manganese Steel Factory Crusher Plate Casting Process Jaw

What is High Manganese Steel Factory Crusher Plate Casting Process Jaw Crusher Parts Jaw Plates, casting manufacturerssuppliers on Video Channel of Made-in-China.

Hard Rock Gold Crusher Crushing Diesel Engine Mobile Type PE

This jaw crusher uses motor as its power, through the motor's wheels, the eccentric shaft is driven by the triangle belt and slot wheel to make the movable jaw plate move by a regulated track. Therefore, the materials in the crushing cavity composed of fixed jaw plate, movable jaw plate and side-lee board can be crushed and discharged through

Jaw Plates: How to Choose the Right One for Different Types of Jaw

2023年2月15日For double toggle jaw crusher plate, the degree of its vertical swing is greater than that of horizontal swing. The greater the vertical swing, the longer the ore slides here, so the wear of jaw plate especially the part near the discharge port is more serious. New jaw plates running in the second-hand jaw crusher

Jaw Rock Crusher Supplies By Trusted Manufacturer AGICO

The rock reduced by jaw crusher is ready for impact crusher and cone crusher to do the medium and fine crushing. Jaw crusher is currently the most common crushers for sale in the world. Equipped with high-manganese-steel jaw plates, it can crush ores, rocks, steel slag, and other hard materials. It can be used in cement plants, quarries, stone

Jaw Crushers MEKA CrushingScreening Plants

Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement. There are also primary and secondary types of these crushers. Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds