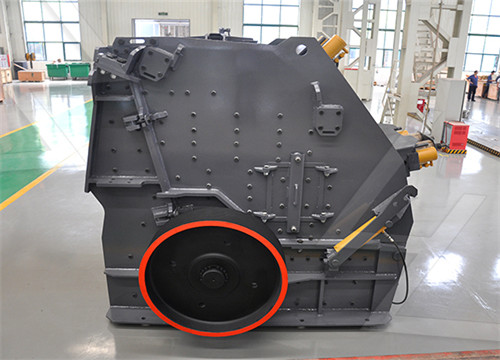

Crushing Machine Rodscrushing Machine Roll Crusher

Roll Crusher ManufacturerDesign Williams Crusher

Roll crushing surfaces operate at a fixed distance apart, as opposed to the continually changing distances in a jaw or cone crusher. This creates a more consistent product size. Roll crushers are low in profile and

Roll Crusher HRC

Roller carriage, and optional lifting device, allow crusher to be moved to safe working space, and roll locking device ensures safety during maintenancewear part

进一步探索

Roll crusher working principle Henan Deya Machinery Co., Roll crushers SlideShare根据热度为您推荐•反馈

Roll Crushers Top 2022 Models 911Metallurgist

Roll Crusher US$ 12,000 8″ Laboratory Roll Crusher 10″ to 12″ Double Roll Crushers US$ 27,000 Roll Crusher for Sale The standard spring roll crusher have two horizontally mounted cylinders. The set is determined

Steele Smooth Roll Crushers Steele Machinery J.C.

Home Machinery Crushing and Grinding Smooth Roll Crusher Steele Smooth Roll Crusher — Medium to fine grinding to produce discs, strips or sheets of material The

Double Roll Crushers McLanahan

McLanahan Double Roll Crushers feature slower roll speeds and a larger surface area to add prolonged life to the crushing elements, resulting in less maintenance downtime and decreasing your cost per ton. Double

Rock Crusher MachinesPulverizers Williams Crusher

What Is a Rock Crusher Used For? A rock crusher is a device used to crush rocks into pieces of your desired size. Rock crushers are most often used for gravel, sand, and

mpl Mineral Processing GmbH, Austria Roll Crusher

The roll crusher WB is used as a secondary and tertiary crusher. Depending on feed material and application soft or hard, abrasive material we have the right type of roll crusher. Depending on the requirements,

Roll Crusher With stable Performance Fote Machinery

Roll crusher, as one of the most economical and practical crushers, is designed to handle the first and second crushing of friable minerals and stones such as coal, clay, coal gangue, limestone, slag, cement clinkers,

Roll crusher installation, operation and maintenance

2021年8月23日(2) The roller crusher must be started first, and after the rotation speed is normal, then can feed material to the machine, and the procedure is reversed when

Product datasheet Eccentric R oll Crusher ERC® 18-14

The symmetrical arrangement of the roll allows the crusher to be balanced with great precision. This significantly reduces machine vibrations and loads on surrounding structures, and makes the crusher ideal for use in both mobile and semi-mobile crushing systems. Technical specification Application data Application Primary crushing

Roll Crusher ManufacturerDesign Williams Crusher

Roll crushing surfaces operate at a fixed distance apart, as opposed to the continually changing distances in a jaw or cone crusher. This creates a more consistent product size. Roll crushers are low in profile and

Roll Crushers McLanahan

Since patenting the first Single Roll Crusher in 1894, McLanahan has become an expert and leader in the industry in the design and manufacture of single and two stage Roll Crushers. The selection process for each application is based on extensive equipment knowledge and a wealth of test data developed in our research lab or through on-site

Eccentric Roll Crusher ERC®

We offer five Eccentric Roll Crusher ERC® types for various applications. 1) Weights indicated do not include base frame, drive motor and tools. Weights may vary depending on actual machine configuration. 2) Motor rating range applicable for < 1,000m altitude. Actual motor rating depending on the feed material characteristics, desired product

Roll Crushers Top 2022 Models 911Metallurgist

Progress in Roll-Crushing. BY C. Q. Payne, New York, N. Y. On the right, a Roll Crushers is shown in a sectional elevation of the A-C single-roll crusher while here below is a cutaway view of the machine, with hopper

Rock Crusher MachinesPulverizers Williams Crusher

What Is a Rock Crusher Used For? A rock crusher is a device used to crush rocks into pieces of your desired size. Rock crushers are most often used for gravel, sand, and other building applications. Some of the most common types of aggregates in rock crushing are sandstone, gravel, and limestone.

Steele Smooth Roll Crushers Steele Machinery J.C. SteeleSons

The Steele Smooth Roll Crusher plays a key role in bulk raw material preparation, processing clays, coal fines, coke breeze and gypsum waste. Twin rollers reduce pebbles and plastic lumps to form thin, flat discs, strips or sheets of material for additional processing or pugging. Crushing and shearing play a critical roll in mix quality, so we

mpl Mineral Processing GmbH, Austria Roll Crusher

The roll crusher WB is used as a secondary and tertiary crusher. Depending on feed material and application soft or hard, abrasive material we have the right type of roll crusher. Depending on the requirements,

Roll crusher installation, operation and maintenance

2021年8月23日(2) The roller crusher must be started first, and after the rotation speed is normal, then can feed material to the machine, and the procedure is reversed when stopping. (3) Regularly check the condition of the material discharging, and clear it if it is found to be blocked.

Double Roll Crushers McLanahan

McLanahan Double Roll Crushers feature slower roll speeds and a larger surface area to add prolonged life to the crushing elements, resulting in less maintenance downtime and decreasing your cost per ton. Double

Double Roller Crusher JXSC Machine

The Doule Roller Crusher, also known as roll crusher, toothed roll crusher, is suitable for fine crush the medium hardness rock with compressive strength ≤160MPa, such as ore, rock, coke, coal, clinker,

Roll Crushers / Granulators Ludman Industries High Precision Crushing

Machine Sizes/Specifications. 9 Inch to 30 Inch Diameter Rolls. 12 Inch to 60 Inch Roll Face Length. Available with 1, 2, or 3 Pairs of Rolls. Throughput Up to 35 Tons/Hour. Up to 50 HP Drives. Roll Differential Speeds to 2:1. In conclusion, our granulators or roll crushers help you to achieve superior product and higher yield.

5 Glass Crushers to Accelerate Your Glass Recycling

2023年2月15日Glass roll crusher A glass roller crusher is one of the most economical and practical glass crushers. It can handle the first and second crushing of wet or sticky glass materials. Glass roller crusher price:$3, 500 Get Latest Price Advantages of glass roller crusher It has an extremely high output.

Types of crushing machines Simple English Wikipedia, the free

Crushers are machines used to reduce the size of rocks, stones and ore. They are often utilized in aggregates production, construction material recycling and in mining operations. [1] There are four traditional types of crushers in materials engineering. They are known as jaw crushers, gyratory crushers, cone crushers and roll crushers.

Product datasheet Eccentric R oll Crusher ERC® 18-14

The symmetrical arrangement of the roll allows the crusher to be balanced with great precision. This significantly reduces machine vibrations and loads on surrounding structures, and makes the crusher ideal for use in both mobile and semi-mobile crushing systems. Technical specification Application data Application Primary crushing

Roll Crushers McLanahan

Since patenting the first Single Roll Crusher in 1894, McLanahan has become an expert and leader in the industry in the design and manufacture of single and two stage Roll Crushers. The selection process for each application is based on extensive equipment knowledge and a wealth of test data developed in our research lab or through on-site

Eccentric Roll Crusher ERC®

We offer five Eccentric Roll Crusher ERC® types for various applications. 1) Weights indicated do not include base frame, drive motor and tools. Weights may vary depending on actual machine configuration. 2) Motor rating range applicable for < 1,000m altitude. Actual motor rating depending on the feed material characteristics, desired product

Roll Crushers Top 2022 Models 911Metallurgist

Progress in Roll-Crushing. BY C. Q. Payne, New York, N. Y. On the right, a Roll Crushers is shown in a sectional elevation of the A-C single-roll crusher while here below is a cutaway view of the machine, with hopper

Double Roll Crushers McLanahan

The crushers are designed with built-in tramp relief that allows for the passing of uncrushable objects while remaining in continuous operation and returning to the initial product setting. With a variety of roll surface

Steele Smooth Roll Crushers Steele Machinery J.C. SteeleSons

Home Machinery Crushing and Grinding Smooth Roll Crusher Steele Smooth Roll Crusher — Medium to fine grinding to produce discs, strips or sheets of material The Steele Smooth Roll Crusher plays a key role in bulk raw material preparation, processing clays, coal fines, coke breeze and gypsum waste.

mpl Mineral Processing GmbH, Austria Roll Crusher

The roll crusher WB is used as a secondary and tertiary crusher. Depending on feed material and application soft or hard, abrasive material we have the right type of roll crusher. Depending on the requirements,

Roll crusher installation, operation and maintenance

2021年8月23日(2) The roller crusher must be started first, and after the rotation speed is normal, then can feed material to the machine, and the procedure is reversed when stopping. (3) Regularly check the condition of the material discharging, and clear it if it is found to be blocked.

Double Roller Crusher JXSC Machine

The Doule Roller Crusher, also known as roll crusher, toothed roll crusher, is suitable for fine crush the medium hardness rock with compressive strength ≤160MPa, such as ore, rock, coke, coal, clinker,

Roll Crushers / Granulators Ludman Industries High

Machine Sizes/Specifications. 9 Inch to 30 Inch Diameter Rolls. 12 Inch to 60 Inch Roll Face Length. Available with 1, 2, or 3 Pairs of Rolls. Throughput Up to 35 Tons/Hour. Up to 50 HP Drives. Roll Differential

5 Glass Crushers to Accelerate Your Glass Recycling

2023年2月15日Glass roll crusher A glass roller crusher is one of the most economical and practical glass crushers. It can handle the first and second crushing of wet or sticky glass materials. Glass roller crusher

Amazing Quarry Primary Rock Crushing Machine Working, Stone YouTube

2020年6月19日Amazing Quarry Primary Rock Crushing Machine Working, Stone Processing by Crusher🔥🔥 Subscribe Fantastic Machinery: bit.ly/2rJL9StDream Catcher by Ke...

Shredder, Extreme powerful crusher machines fast crushing YouTube

Shredder, Extreme powerful crusher machines fast crushing everything for new recycle !Remember to watch the video, subscribe, share to support my channel dir...

Different types of crushing equipments Constro Facilitator

2020年5月6日Types of crusher depend on the feeding method. These are- Primary crusher, Secondary crusher and Tertiary crusher. The primary crusher is only for the breaking of large stones into pieces (this means primary crusher is not for the aggregate size material.). Examples of primary crushers are jaw crusher; hammer mill crusher