Grinding Silos At Ore Plants

(PDF) Overview of Mineral Processing Methods

2015年8月3日Abstract and Figures. The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or

Gold Ore Roasting Plant Mineral ProcessingMetallurgy

2016年5月31日Ground ore is discharged from the grinding mill product recovery baghouse and collected in the roaster feed silos. One silo is

11.21 Phosphate Rock Processing US EPA

plant for future use. The rock is slurried in water and wet-ground in ball mills or rod mills at the chemical plant. Consequently, there is no significant emission potential from wet

Iron Ore Pelletizing Process: An Overview IntechOpen

2018年7月11日The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore

Ore Bin (Silo) Safety Mineral ProcessingMetallurgy

2015年7月27日If there is work to do inside the fine ore bins, the bulk of the work will be preparing the bins so that it is possible to work safely in them. This job doesn’t come up

Iron ore grinding millGrinding plants for Iron Ore

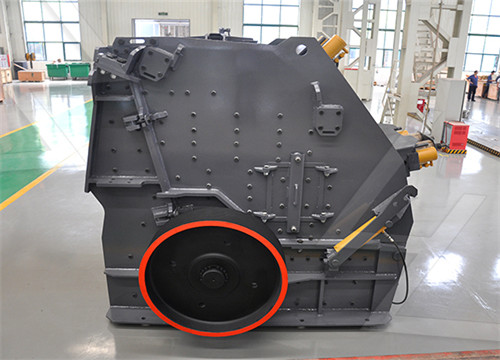

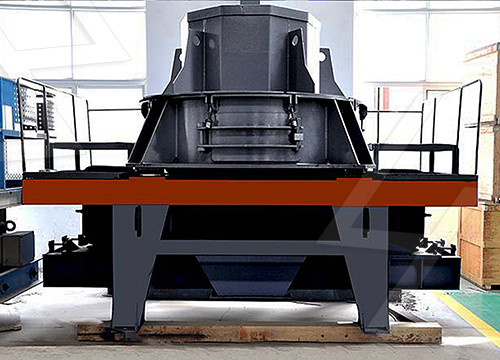

Iron Ore powder processing technological process. Phrase one: raw material crushing. Iron ore blocks will be crushed to 15mm-50mm fineness by crusher. Phrase two: grinding.

(PDF) MPS mills for coal grinding researchgate.net

2014年1月1日January 2002 ZKG INTERNATIONAL. H. Gilabert. Since the beginning of 2002, Industrias Rocacem S.A has been operating an MPS 4250 BC roller mill at their

Grinding Mill Plants Producing Millstones for more than 120 years

The Baker´sMiller’s Choice Grinding Mill Plants come in various sizes and capacities, are modular, adaptable, and fitted with cleaner, polisher, buffer silos, etc. depending on

Grinding Silos At Ore Plants thisweekinfedora

Loesche is furthermore transferring the modular CCG concept to coal grinding plants CGP and compact ore grinding plants OCP. CMBI Sinoma, the other supplier for modular

grinding silos at ore plants

Tata Steel installs record size iron ore drying and grinding plant . May 1, 2010 is supplying an iron ore drying grinding plant for a 6m in an jet pulse baghouse and conveyed to the

Influence of Grinding and Classification Circuit on the Performance

2019年12月17日ABSTRACT. Process flowsheet has a greater effect on equipment performance and operating conditions. For this purpose, performance of two iron ore beneficiation plants with the same equipment and feed characteristics but different arrangements in the grinding and classification circuit has been investigated.

Mineral Processing Plant Design University of Technology, Iraq

storage capacity of bins and silos. To address this problem, chutes must be easily accessible for clean-up, and large feeder openings must be provided for bins, silos and tunnels. If it is practical to obtain representative ore samples, it is prudent to have testwork

cdc.gov

ducting an indepth survey of this plant. INTRODUCTION the ore to the concentrator fine ore storage silos. From the storage silos, ore is proportionally mixed with water and fed into the grinding circuit, successively ground by a 13 1/2 x 16 foot rod mill and a 15 x 19

17 Signs of Problems with Ball Mills: Quickly Remove Hidden Troubles

2023年2月15日High temperature of the ball mill will affact the efficiency. 3 For every 1% increase in moisture, the output of the ball mill will be reduced by 8% -10%. 4 when the moisture is greater than 5%, the ball mill will be unable to perform the grinding operation. 5. The bearing of the ball mill is overheated and the motor is overloaded.

Iron Ore Processing,Crushing,Grinding Plant Machine

The stage grinding-magnetic separation process mainly utilizes the characteristics of magnetite that can be enriched under coarse grinding conditions, and at the same time, it can discharge the characteristics of single gangue, reducing the

Manganese Ore Processing Mineral ProcessingMetallurgy

2016年4月27日The Manganese Ore Processing Plant Crushing and Sampling of Manganese Rock The flowsheet incorporates a conventional multistage crushing plant with a grizzly or screen ahead of both the primary and secondary crushers. The mine run ore is dumped through a 10″ grizzly into a coarse ore bin.

10 Best Ore Beneficiation Plants for Sale (with Costs)

2021年3月24日A complete ore beneficiation plant has four stages: screening and crushing, mill grinding process, beneficiation process, and ore drying process. 2 Mill grinding process 3 Beneficiation process 4 Ore drying process 1 Screening and crushing 2 Mill grinding process 3 Beneficiation process 4 Ore drying process 1 Screening and

(PDF) MPS mills for coal grinding researchgate.net

2014年1月1日January 2002 ZKG INTERNATIONAL. H. Gilabert. Since the beginning of 2002, Industrias Rocacem S.A has been operating an MPS 4250 BC roller mill at their Latacunga grinding plant in Ecuador. The

Grinding Silos At Ore Plants thisweekinfedora

Loesche is furthermore transferring the modular CCG concept to coal grinding plants CGP and compact ore grinding plants OCP. CMBI Sinoma, the other supplier for modular cement grinding plants, uses one ball mill type with a grinding capacity of 35 th or 0.25 Mta as well as a VRM with a capacity of up to 70 th or 0.5 Mta in its MMG

grinding silos at ore plants

Tata Steel installs record size iron ore drying and grinding plant . May 1, 2010 is supplying an iron ore drying grinding plant for a 6m in an jet pulse baghouse and conveyed to the ground silo by Get Quote WhatsApp; milling control optimisation Mintek. Silo. Feeders. Mill. Time Delay. (40 SEC). Time (seconds). Solids flow.

Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant

2014年10月1日In a test performed in the Loesche test center in Germany, copper slag grinding saved 22.9% energy in an air-swept model and 34.4% energy in an overflow model [13,14].

AP-42 9.9.1 Grain Elevators And Processes US EPA

is passed through an impact machine as a final cleaning step. The wheat flows into a grinding bin and then into the mill itself. The grain kernels are broken open in a system of breaks by sets of corrugated rolls, each set taking feed from the preceding one. After each break, the grain is sifted. The sifting system is a

Iron Ore Pelletizing Process: An Overview IntechOpen

2018年7月11日The iron ore pelletizing process consists of three main steps: Pelletizing feed preparation and mixing: the raw material (iron ore concentrate, additives—anthracite, dolomite—and binders are prepared in terms of particle size and chemical specifications, dosed, and mixed together to feed the pelletizing process;

Iron ore grinding millGrinding plants for Iron Ore

Iron Ore powder processing technological process. Phrase one: raw material crushing. Iron ore blocks will be crushed to 15mm-50mm fineness by crusher. Phrase two: grinding. Crushed iron ore blocks will be sent to the storage hopper by elevator, and then sent to main mill for grinding through feeder. Phrase three: classifying.

Influence of Grinding and Classification Circuit on the Performance

2019年12月17日ABSTRACT. Process flowsheet has a greater effect on equipment performance and operating conditions. For this purpose, performance of two iron ore beneficiation plants with the same equipment and feed characteristics but different arrangements in the grinding and classification circuit has been investigated.

Mineral Processing Plant Design University of Technology, Iraq

storage capacity of bins and silos. To address this problem, chutes must be easily accessible for clean-up, and large feeder openings must be provided for bins, silos and tunnels. If it is practical to obtain representative ore samples, it is prudent to have testwork

Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant

2014年10月1日In a test performed in the Loesche test center in Germany, copper slag grinding saved 22.9% energy in an air-swept model and 34.4% energy in an overflow model [13,14].

17 Signs of Problems with Ball Mills: Quickly Remove Hidden Troubles

2023年2月15日High temperature of the ball mill will affact the efficiency. 3 For every 1% increase in moisture, the output of the ball mill will be reduced by 8% -10%. 4 when the moisture is greater than 5%, the ball mill will be unable to perform the grinding operation. 5. The bearing of the ball mill is overheated and the motor is overloaded.

Manganese Ore Processing Mineral ProcessingMetallurgy

2016年4月27日The Manganese Ore Processing Plant Crushing and Sampling of Manganese Rock The flowsheet incorporates a conventional multistage crushing plant with a grizzly or screen ahead of both the primary and secondary crushers. The mine run ore is dumped through a 10″ grizzly into a coarse ore bin.

cdc.gov

ducting an indepth survey of this plant. INTRODUCTION the ore to the concentrator fine ore storage silos. From the storage silos, ore is proportionally mixed with water and fed into the grinding circuit, successively ground by a 13 1/2 x 16 foot rod mill and a 15 x 19

Grain Handling Occupational Safety and Health Administration

Grain handling facilities are facilities that may receive, handle, store, process and ship bulk raw agricultural commodities such as (but not limited to) corn, wheat, oats, barley, sunflower seeds, and soybeans. Grain handling facilities include grain elevators, feed mills, mills, limestone mills, dust pelletizing plants, dry corn mills

10 Best Ore Beneficiation Plants for Sale (with Costs)

2021年3月24日A complete ore beneficiation plant has four stages: screening and crushing, mill grinding process, beneficiation process, and ore drying process. 2 Mill grinding process 3 Beneficiation process 4 Ore drying process 1 Screening and crushing 2 Mill grinding process 3 Beneficiation process 4 Ore drying process 1 Screening and

Freeze Proofing Morris Chemical

Spray belts with 0.12 gal./sq. yd. to remove ice films. For temperatures below 0°F, use 0.25 gal./sq. yd. and repeat periodically until the ice is gone. Silos, ore bins and bunkers. Spray the interiors and bottoms with liquid CaCl2 and apply it to the material as it is loaded to prevent severe freezing.

(PDF) MPS mills for coal grinding researchgate.net

2014年1月1日January 2002 ZKG INTERNATIONAL. H. Gilabert. Since the beginning of 2002, Industrias Rocacem S.A has been operating an MPS 4250 BC roller mill at their Latacunga grinding plant in Ecuador. The

AP-42 9.9.1 Grain Elevators And Processes US EPA

is passed through an impact machine as a final cleaning step. The wheat flows into a grinding bin and then into the mill itself. The grain kernels are broken open in a system of breaks by sets of corrugated rolls, each set taking feed from the preceding one. After each break, the grain is sifted. The sifting system is a

Iron ore grinding millGrinding plants for Iron Ore

Iron Ore powder processing technological process. Phrase one: raw material crushing. Iron ore blocks will be crushed to 15mm-50mm fineness by crusher. Phrase two: grinding. Crushed iron ore blocks will be sent to the storage hopper by elevator, and then sent to main mill for grinding through feeder. Phrase three: classifying.

Fire and Explosion Hazards in Cement Manufacturing Industries

Step #2: DryingGrinding The crushed rock obtained from quarries is taken to a mix bed plant where the raw material components are pre-homogenized, dried and ground. Raw materials generally contain moisture and need to be dried before or

1 Asphalt, Kirk-Othmer Encyclopedia of Chemical Technology,

When air lifted ore reaches the surface it enters a baghouse. The larger pieces drop first, and the rest is collected in filter bags. All solids are discharged into elevated storage bins and are then transferred by truck to a processing plant. American Gilsonite's plant consists of concrete storage silos, truck receiving bins, a vibrating bed