Cone Vs Gyratory Crushers

Gyratory and Cone Crusher ScienceDirect

2016年1月1日Primary crushers are solidly built to receive large lumps of rock directly from the mines and designed for large tonnage throughputs. Basically, gyratory

Cone Crusher an overview ScienceDirect Topics

The cone crusher is a modified gyratory crusher. The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is

进一步探索

Cone Crusher Working Principle Animation Engineering What is the working principle of the Cone Crusher? Quora根据热度为您推荐•反馈

What Are the Differences Between The 7 Types of Crushers?

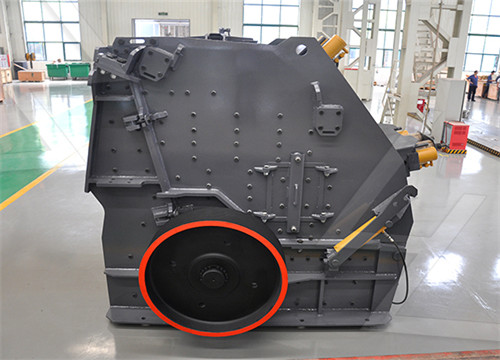

2023年2月15日Cone crusher looks like gyratory crusher but without a steep crushing chamber. Just like jaw crusher, it is also a compression type crusher whose reduction

Cone Crusher VS Gyratory Crusher JXSC Mine JXSC

The cone crusher has 2.5 times higher rotating speed and 4 times larger swinging angle than the gyratory crusher, so the ore is impacted

Gyratory Crusher Explained saVRee

Cone Crushers Typically, the initial crushing stage is completed using either gyratory crushers or jaw crushers. It is often the case that there will be only one crusher installed, and this will be referred to as the ‘ Primary

What Type of Crusher Is Best for Primary Crushing?

2021年3月25日Cone Crushers are compression-type crushers that are typically found in secondary crushing stages but can be used as the primary crusher in certain applications. They handle medium hard to

Gyratory and Cone Crushers 911metallurgist

2015年11月21日A quick look at a machine will allow you to determine if it is a gyratory or a cone In simple terms, if you look at the top of the crusher and it has supporting arms

Difference between ConeGyratory Crusher

2009年1月28日cone vs gyratory crushers Gyratory crushers are for primary crushing. Normally used for Crushing crushing minerals as mined. The size of crusher bowl will

Jaw Crusher VS Cone Crusher Advantages and

Cone crusher is usually used as secondary crusher or three-stage crusher machine. Jaw crusher and cone crusher are usually arranged on the stone crusher plant in two stages. Jaw crusher breaks the rock to 10 ~ 30 cm

Gyratory and Cone Crusher ScienceDirect

2016年1月1日Basically, gyratory crushers consist of a fixed solid conical shell or bowl (also called concaves) and a solid cone within the bowl called a breaking head ( Figure 5.1 ). The breaking head is fixed to a central spindle, which is hydraulically suspended or mechanically held from a spider.

Gyratory Crusher an overview ScienceDirect Topics

A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides. Material is crushed when the crushing surfaces approach each other and the crushed products fall through the discharging opening.

Types of Rock Crushers Quarry Crushing Equipment

Cone crushers can accept medium-hard to very hard and abrasive feeds that might be dry or wet, though not sticky (whereas gyratory crushers are better at handling softer, dryer feeds). Their output will be a relatively

Choosing the Right Rock Crushing Equipment Amcast

2017年7月26日A cone crusher is similar to a gyratory crusher because it operates using a mantle that rotates within a bowl, but it has less steepness in the crushing chamber. It has a short spindle which is supported by a curved universal bearing located beneath the cone.

Jaw Crusher VS Cone Crusher Advantages and

Cone crusher is usually used as secondary crusher or three-stage crusher machine. Jaw crusher and cone crusher are usually arranged on the stone crusher plant in two stages. Jaw crusher breaks the rock to 10 ~ 30 cm

Principle of a cone or gyratory crusher. ResearchGate

The reader is referred to Svensson and Steer (1990) for a discussion about the physics involved in rock crushing inside a cone crusher; Bearman and Briggs (1998), Lindqvist and Evertsson (2006

Difference between ConeGyratory Crusher

2009年1月28日cone vs gyratory crushers Gyratory crushers are for primary crushing. Normally used for Crushing crushing minerals as mined. The size of crusher bowl will match size of boulders. Cone crushers are used for secondary or tertiary crushing for making a cubical product for feeding to process equipment. vinayak sathe 15, Rangavi

Cone Crushers VS Impact Crushers, Which Is Better?

2023年3月7日As we all know, impact crushers and cone crushers are all used for the second crushing line, so which one is better between them? Next comparison from the following 7 aspects. 1.

BOULDER JAM IN KOBELCO GYRATORY CONE CRUSHER YouTube

2021年5月14日#viral #viralvideos #ironore #ironorecrushing #ironoreprocessing #kobelcogyratoryconecrushers #kobelco #crushers #boulderjamincrusher #ironoremining

CH440 Cone Crusher With A Robust Crusher

CH440 Cone crusher. CH440 cone crusher is an advanced design, with a small footprint and high capacity in relation to size, and a hydraulically supported main shaft that is supported at both ends.

Gyratory VS Jaw Crushers: Advantages

2016年2月28日Routine maintenance and repair jobs are generally more easily accomplished on the jaw crusher than on the gyratory. Major repairs are about a stand-off. For crushing extremely hard, tough materials

Compare Gyratory Crusher vs Jaw Crusher Mineral Processing

2015年7月18日The gyrator crusher consists of a truncated conical casing, inside which a crushing head rotates eccentrically. The crushing head is shaped as an inverted cone and the material being crushed is trapped between the outer fixed, and the inner gyrating, cones, and it is again forced into a narrower and narrower space during which time it is crushed.

Компания mmd group ofpanies crusher github

Contribute to businessgitv/ru development by creating an account on GitHub.

Tips for Crusher Maintenance Thomasnet

2018年11月28日Cone crushers use a rotating spindle with a hard encasement mantel to break down materials between the hardened surface and concave bowl. As materials fall through this compression area into a secondary area, the material is crushed again.

Cone Crusher an overview ScienceDirect Topics

The breaking head gyrates inside an inverted truncated cone. These crushers are designed so that the head-to-depth ratio is larger than the standard gyratory crusher and the cone angles are much flatter and the slope of the mantle and the

Choosing the right crusher Buying Guides DirectIndustry

The way a cone crusher operates is similar to how a gyratory crusher does, but in a cone crusher the slope in the breaking space is not as steep. Although it is known for its ability to crush hard and abrasive ores and rocks, the cone crusher is better suited for secondary crushing. It is designed to crush pre-dimensioned materials, generally

Selecting the Right Crushing Equipment Agg-Net

Cone and gyratory crushers Cone and gyratory crushers are both gyrating-shaft machines. They have a main shaft that gyrates and provides the crushing motion. Crushing takes place between a fixed outer

CH440 Cone Crusher With A Robust Crusher

CH440 Cone crusher. CH440 cone crusher is an advanced design, with a small footprint and high capacity in relation to size, and a hydraulically supported main shaft that is supported at both ends.

Should I Choose an Impact Rock Crusher or Cone

Cone crushers have less reduction and are sensitive to contamination, however they’re the best finishing crusher to create a consistent, high quality product. Cone crushers are typically used for: Secondary or

Principle of a cone or gyratory crusher. ResearchGate

is no significant difference between cone and gyratory crushers. In both types, the crushing action is achieved by an eccentric gyratory movement of the main shaft axis, as shown in...

Gyratory VS Jaw Crushers: Advantages

2016年2月28日Routine maintenance and repair jobs are generally more easily accomplished on the jaw crusher than on the gyratory. Major repairs are about a stand-off. For crushing extremely hard, tough materials

Cone Crushers VS Impact Crushers, Which Is Better?

2023年3月7日As we all know, impact crushers and cone crushers are all used for the second crushing line, so which one is better between them? Next comparison from the following 7 aspects. 1.

BOULDER JAM IN KOBELCO GYRATORY CONE CRUSHER YouTube

2021年5月14日#viral #viralvideos #ironore #ironorecrushing #ironoreprocessing #kobelcogyratoryconecrushers #kobelco #crushers #boulderjamincrusher #ironoremining

IRON ORE BOULDER CRUSHING BY KOBELCO

IRON ORE CRUSHING BY KOBELCO GYRATORY CONE CRUSHER TOP VIEW#technical_info_fe2o3#conecrusher #crushing #boulder #crusherplant #crushingplant #kobelco #ore #k...

Compare Gyratory Crusher vs Jaw Crusher Mineral Processing

2015年7月18日The gyrator crusher consists of a truncated conical casing, inside which a crushing head rotates eccentrically. The crushing head is shaped as an inverted cone and the material being crushed is trapped between the outer fixed, and the inner gyrating, cones, and it is again forced into a narrower and narrower space during which time it is crushed.

Crusher an overview ScienceDirect Topics

The cone crusher (Fig. 13.12) is very similar to the gyratory type, except that it has a much shorter spindle with a larger-diameter crushing surface relative to its vertical dimension. The spindle is not suspended as in the gyratory crusher. The eccentric motion of the inner crushing cone is similar to that of the gyratory crusher.

P&Q University Lesson 7: CrushingSecondary Breaking

2019年9月2日Cone crushers are similar to gyratory crushers in that they have a mantle that rotates within a bowl, but the chamber is not as steep. They are compression crushers that generally provide reduction ratios of 6-to-1 to 4-to-1. Cone crushers are used in secondary, tertiary and quaternary stages.