Changing Impact Crusher Breakers In Crusher

Tips to maximize crushing efficiency PitQuarry

2019年5月13日Feeding impact crushers. Size reduction in an impact crusher relies on energy being conveyed into the rock from the rotor, and it begins with your feed. The

P&Q University Lesson 7- CrushingSecondary Breaking

2019年9月2日Impact crushers are increasingly used for crushing recycling material. Impact crushers are capable of producing mineral aggregate mixes in one single

What to Do about Lumps: Selecting Crushers and Lump

2012年4月24日You can use a crusher/lump breaker to solve many processing problems, including preparing your material for conveying,

What Type of Crusher Is Best for Primary Crushing?

2021年3月25日The material enters the crusher and shatters upon impact with swinging hammers that are secured to a spinning rotor. The particles rebound off the breaker plates into the hammer circle and are carried

HSI Crushers Armstrong Equipment

® Cedarapids 1300 Series Impact Crushers. Quick impeller bar changes and quick change breaker plates allow for better control of product size. Rugged design and

Service Tip Replacement of blow bars on a NP impact

2021年9月16日The blow bars on a NP impact crusher are reversible. When one side is worn out, the blow bar can be rotated so that the other side can be used. To avoid any

Impact crushers and impact mills with a horizontal shaft

The impact crusher can be repurposed into an impact mill for manufacturing finer grains by inserting a higher machine base and an additional grinding track. This flexible solution

Change Crusher Blow Bars MGS Casting

When transforming and reversing crusher blow bars, adhere to the directions in the Impact crusher instruction manual. Replacement Procedure: 1. Tidy the material of the influence crusher mouth prior to

effect of changing speed of impact crusher MiningQuarry Plant

2013年8月11日Impact crusher machine,Impact breaker,Impact crushing machine Impact crusher (impact breaker) is the hammers take effect, under the impact role

Impact Crusher an overview ScienceDirect Topics

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 4.4).A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 4.4(a)) and it is the most widely used in primary crushing stages (Behera et al., 2014).

® NP Series™ impact crushers Metso Outotec

The crusher configuration can be adjusted for your requirements. Options like full hydraulic adjustment, third breaker plate, different grades of steel and cast iron for the active wear parts, enable customizing the crusher exactly for your needs.

Tips to maximize crushing efficiency PitQuarry

2019年5月13日Feeding impact crushers. Size reduction in an impact crusher relies on energy being conveyed into the rock from the rotor, and it begins with your feed. The initial impact is responsible for more than 60 percent of the crushing action, with the remainder made up of impact against an adjustable breaker bar and a small amount of inter

Tertiary Impact Crushers MEKA Crushing

TERTIARY IMPACT CRUSHER. Designed for crushing soft and medium-hard materials with close grain distribution and cubical products, tertiary impact crushers are an excellent solution in the production of fine

Rock Crushing Rule of Thumb Mineral ProcessingMetallurgy

2015年12月16日The Crusher’s Rock Breakers. The capacity of a hydraulic rock breaker is higher (and the operating cost lower) than a pneumatic rockbreaker. For these reasons, most new installations are hydraulic, despite the higher capital cost. Impact crusher pulverizers, shredders or smooth roll: feed diameter 1 cm with a reduction ratio of 7:1 to

What to Do about Lumps: Selecting Crushers and

2012年4月24日Crushers and lump breakers are used to reduce lumps in chemicals, pharmaceuticals, s, agricultural feeds, pet , aggregates, and other materials, to a consistent size. The offerings range from slow

Feeder Breaker HFB

The Feeder Breaker HFB is a complete horizontal roll crusher plant, which operates on the field-proven principle of crushing in the horizontal material flow. The Feeder Breaker consists primarily of two machine components: the crushing roll and the chain conveyor. The arrangement of the crushing roll above the chain conveyor allows the

Roll Crusher ManufacturerDesign Williams Crusher

Roll Crushers are simple in design and construction, long-lasting, economical, and versatile across many applications and industries. A combination of impact, shear, and compression are the forces

What is a Primary Crusher? machinerypartner

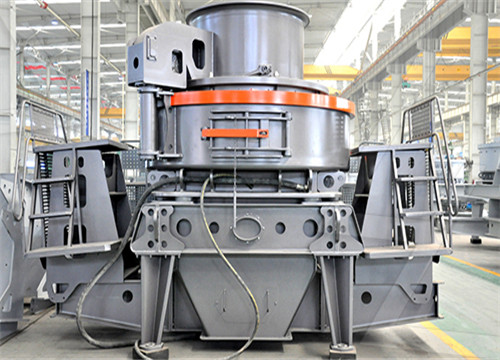

Impact crushers can be used at any stage of the crushing process. They have a rotor that has “hammers”. These hit the material being fed into the machine and throw it against impact plates inside the crusher breaking it down. Reduction ratio = 10:1 Inside an impact crusher How to crush large rocks into smaller stones

effect of changing speed of impact crusher MiningQuarry Plant

2013年8月11日Impact crusher (impact breaker) is the hammers take effect, under the impact role of the hammer at a high speed, the materials are thrown to the impact device The Effects of Change On The Manager Free Articles

Changing Impact Crusher Breakers In mpl Cruhers

want to sell rock breakers mpl Crusher Solutions. i want to sell my tata hitachi 200 with rock breaker. in good condition u can call me on=

Crusher an overview ScienceDirect Topics

The impact crusher ( Fig. 13.15) employs high-speed impact or sharp blows to the free-falling feed rather than compression or abrasion. It utilizes hinged or fixed heavy metal hammers (hammer mill) or bars attached to the edges of horizontal rotating discs.

sbm/sbm changing impact crusher breakers in mpl crusher

Contribute to chengxinjia/sbm development by creating an account on GitHub.

What is the best type of crusher for hard rock?

2023年3月7日mpl China. The best type of crusher for hard rock is a jaw crusher. Jaw crushers can handle very large pieces of rock, and are able to produce a finely crushed product with a relatively small

® NP Series™ impact crushers Metso Outotec

High performance. ® NP Series™ HSI crushers consist of heavy rotor, wear resistant materials, and an optimal crushing chamber design. This combination has proven revolutionary in improving capacity and product quality, as well as in reducing operating and wear costs. ® NP™ crushers have a unique blow bar attachment system.

Impact Crusher an overview ScienceDirect Topics

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 4.4).A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 4.4(a)) and it is the most widely used in primary crushing stages (Behera et al., 2014).

Tertiary Impact Crushers MEKA Crushing

TERTIARY IMPACT CRUSHER. Designed for crushing soft and medium-hard materials with close grain distribution and cubical products, tertiary impact crushers are an excellent solution in the production of fine

Rock Crushing Rule of Thumb Mineral ProcessingMetallurgy

2015年12月16日The Crusher’s Rock Breakers. The capacity of a hydraulic rock breaker is higher (and the operating cost lower) than a pneumatic rockbreaker. For these reasons, most new installations are hydraulic, despite the higher capital cost. Impact crusher pulverizers, shredders or smooth roll: feed diameter 1 cm with a reduction ratio of 7:1 to

What to Do about Lumps: Selecting Crushers and

2012年4月24日Crushers and lump breakers are used to reduce lumps in chemicals, pharmaceuticals, s, agricultural feeds, pet , aggregates, and other materials, to a consistent size. The offerings range from slow

Feeder Breaker HFB

The Feeder Breaker HFB is a complete horizontal roll crusher plant, which operates on the field-proven principle of crushing in the horizontal material flow. The Feeder Breaker consists primarily of two machine components: the crushing roll and the chain conveyor. The arrangement of the crushing roll above the chain conveyor allows the

Roll Crusher ManufacturerDesign Williams Crusher

Roll Crushers are simple in design and construction, long-lasting, economical, and versatile across many applications and industries. A combination of impact, shear, and compression are the forces

What is a Primary Crusher? machinerypartner

Impact crushers can be used at any stage of the crushing process. They have a rotor that has “hammers”. These hit the material being fed into the machine and throw it against impact plates inside the crusher breaking it down. Reduction ratio = 10:1 Inside an impact crusher How to crush large rocks into smaller stones

How to change the blow bars on an impact crusher?

2023年3月7日You can change the blow bars on an impact crusher by removing the old blow bars, cleaning the area where the new blow bars will be mounted, and placing the new blow bars in the desired area.

effect of changing speed of impact crusher MiningQuarry Plant

2013年8月11日Impact crusher machine,Impact breaker,Impact crushing machine Impact crusher (impact breaker) is the hammers take effect, under the impact role of the hammer at a high speed, the materials are thrown to the impact device The Effects of Change On The Manager Free Articles

sbm/sbm changing impact crusher breakers in mpl crusher

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Impact Crushers Primary McLanahan

Impact Crushers Primary Impact Crushers create material reduction by providing a sudden impact force that causes the material to shatter along all the weakest fissures in the stone.

Changing Impact Crusher Breakers In mpl Cruhers

want to sell rock breakers mpl Crusher Solutions. i want to sell my tata hitachi 200 with rock breaker. in good condition u can call me on=

® NP1415™ impact crusher Metso Outotec

Easy maintenance. NP1415™ is designed to be mechanically resistant. Whenever maintenance is required, changing parts is made simple and easy. Patented RPS (Rotor Positioning System) is available as manual or electrical. This new device complies with future EN1009 standard and is a key accessory for safe maintenance of the crusher.