Roll Crusher Lining Plates Roll Crusher Lining Boards Roll Crusher Liners

Crusher Liners Cone Crusher Liners Crushing Wear Parts

932 行Crusher Liners CSP is a leading supplier of cast, forged, and fabricated wear solutions to OEM and aftermarket crusher operators.

Single Roll Crushers McLanahan

根据热度为您推荐•反馈

Roll Crushers McLanahan

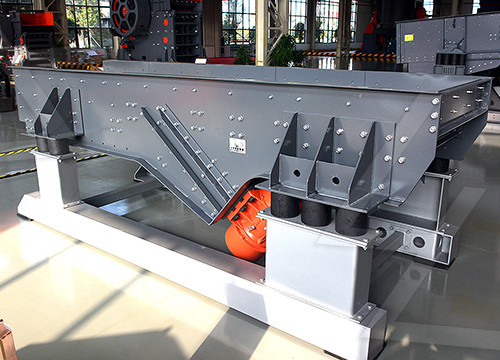

Roll Crushers Roll Crushers are designed to handle the primary, secondary and tertiary stage crushing of friable materials such as coal, salt, clay, bauxite, limestone and other

进一步探索

Single Roll Crushers McLanahanUsed Two Roll Crusher for sale. Kpi-Jci equipmentmore 根据热度为您推荐•反馈

Roll Crusher ManufacturerDesign Williams Crusher

Contact our sales engineers! Contact us today to discuss your application in detail with one of our experienced sales engineers. Call (314) 621-3348, email us at info@williamscrusher or locate an agent near you.

Roll Crusher an overview ScienceDirect Topics

Both single-roll and double-roll crushers are designed with tramp oversize protection, which allows either the stationary crushing plate (in singleroll systems) or one of the

Crusher Liners H-E Parts

CME™ Crusher Liners H-E Parts has built a reputation on the reliability and performance of its CME™ range of manganese crusher liners, which are designed to be fully

Lancaster Products Roll Crusher for Glass Manufacturing

Lancaster Products Roll Crushers are designed for long life. These crushers reduce in a single pass- material previously requiring primary and secondary crushing. 800.447.7351. About Us; Replaceable comb

Roll Crusher Manufacturer Propel Industries

ROLL CRUSHER AVRC SERIES. New generation Roll Crusher has been designed using latest engineering tools for high reliability. It has premium features like high-efficiency

Change crusher liners Wear Parts For Industry Qiming

Change crusher liners When to change crusher liners It is an important thing when to change crusher liner, so as to avoid damage to the liner seating surfaces of the crusher bowl, concave and mantle must be

Eccentric Roll Crusher ERC®

Product features Downloads Key Benefits High throughputs up to 8,000 tph Compact and robust design Integrated screening chamber increased productivity Lower power

Roll Crusher wear parts Cast Steel Products

FEATURESBENEFITS Proprietary work hardening alloys including Manganese for reduced maintenance and increased uptime. Decreased downtimes and increased cost savings. Better fit for quick and easy replacement. Design improvements increase crusher efficiency and prevent premature erosion.

Roll Crusher ManufacturerDesign Williams Crusher

How Roll Crushers Work Roll Crushers are simple in design and construction, long-lasting, economical, and versatile across many applications and industries. A combination of impact, shear, and

Roll Crusher an overview ScienceDirect Topics

Both single-roll and double-roll crushers are designed with tramp oversize protection, which allows either the stationary crushing plate (in singleroll systems) or one of the toothed rolls (in double-roll systems) to move and open up the gap if a large, unbreakable piece enters the machine.

Roll Crushers TAKRAF TAKRAF GmbH

Roll Crushers Roll Crushers Roll crushers are customized solutions for new or existing crushing plants. TAKRAF roll crushers are designed for capacities of up to 14,000 t/h and are driven by powerful drive units in order to even crush hard

Lancaster Products Roll Crusher for Glass Manufacturing

Lancaster Products Roll Crushers are designed for long life. These crushers reduce in a single pass- material previously requiring primary and secondary crushing. 800.447.7351. About Us; Replaceable comb plates and cheek plates at the ends and sides of the housing prevent material from bypassing the rolls.

Improved wear life via reliable Jaw Crusher Liners

Jaw Crusher Liners built from technologically advanced designs You are looking for wear liners that are proven to work for your applications, and that promote maximum productivity. Our jaw crusher liner expertise and high-quality materials are key to creating an optimised crushing solution customised to your unique needs.

Crusher Liners H-E Parts

CME™ Crusher Liners H-E Parts has built a reputation on the reliability and performance of its CME™ range of manganese crusher liners, which are designed to be fully compatible with H-E Parts variety of lifting devices, that ensure safety and efficiency are achieved in all service functions.

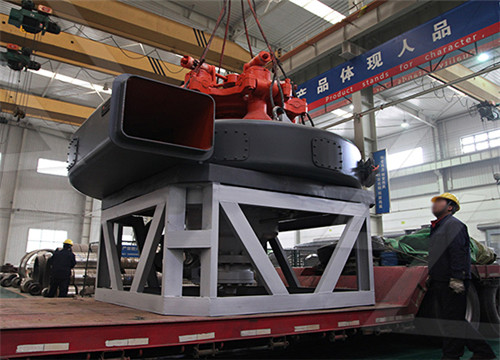

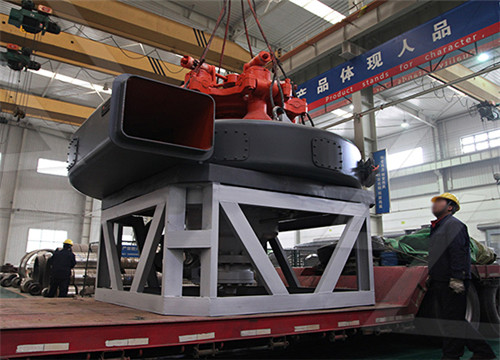

Qiming Casting-China’s wear-resistant casting industry leader

Qiming Casting produces wear parts in standard materials according to the actual needs of our customers. For example, high manganese crusher jaw plates, cone crusher liners, and side plates for stone crushers; High chrome steel rollers for vertical mills; Cr-mo alloy steel liners for ball mills. Redefining Wear Parts

Ball mill liner Wear Parts For Industry Qiming Casting

As a wear-resistant foundry, Qiming Casting manufactures manganese steel, Cr-Mo alloy steel, and Ni-hard steel liners for all kinds of ball mills, which include: single wave liners, modified single wave liners, double wave liners, shell liners, feed head liners, and discharge end liners. Qiming Casting is Your Foundry for Ball Mill Liners!

Crusher an overview ScienceDirect Topics

Advanced roll crushers are designed with one rotating cylinder that rotates toward a fix plate or rollers with differing diameters and speeds. It improves the liberation of minerals in the crushed product. Roll crushers are very often used in limestone, coal, phosphate, chalk, and other friable soft ores. Sign in to download full-size image

Sampling Sizers/Roll Crushers McLanahan

Applications. Sampling Sizers/Roll Crushers retain the key features and benefits of the larger machine designs but are packaged into compact, cost-effective solutions specifically tailored to reliably and efficiently handle lower capacity applications. Double Roll Crushers are a widely used crusher type and offer advantages in relatively high

Roll Crusher Manufacturer Propel Industries

ROLL CRUSHER AVRC SERIES. New generation Roll Crusher has been designed using latest engineering tools for high reliability. It has premium features like high-efficiency gear drive and hydraulic gap management. Its features and the unique design help manufacture sand at lowest possible power consumption and liner wear cost.

Roll crusher Henan Deya Machinery Co., Ltd.

2021年9月16日Roll crushers consist of two or more adjacent rolls placed parallel to each other and rotated in opposite directions. Single roll crushers are also available which rotate a single roll against a fixed breaker plate. Mineral or rock particles placed between the rolls are nipped and then crushed as they pass between the rolls.

Mid-range rolls crushers tough on any material

Essa RC3000 Rolls Crusher a larger and much more powerful rolls crusher with 2 x 350 mm rolls. A choice of two configurations gives you flexibility for continuous or batch use in laboratory and plant applications.

Eccentric Roll Crusher ERC®

We offer five Eccentric Roll Crusher ERC® types for various applications. 1) Weights indicated do not include base frame, drive motor and tools. Weights may vary depending on actual machine configuration. 2) Motor rating range applicable for < 1,000m altitude. Actual motor rating depending on the feed material characteristics, desired product

Roll Crusher ManufacturerDesign Williams Crusher

How Roll Crushers Work Roll Crushers are simple in design and construction, long-lasting, economical, and versatile across many applications and industries. A combination of impact, shear, and

Roll Crusher an overview ScienceDirect Topics

Both single-roll and double-roll crushers are designed with tramp oversize protection, which allows either the stationary crushing plate (in singleroll systems) or one of the toothed rolls (in double-roll systems) to move and open up the gap if a large, unbreakable piece enters the machine.

Roll Crushers TAKRAF TAKRAF GmbH

Roll Crushers Roll Crushers Roll crushers are customized solutions for new or existing crushing plants. TAKRAF roll crushers are designed for capacities of up to 14,000 t/h and are driven by powerful drive units in order to even crush hard

Mid-range rolls crushers tough on any material

Essa RC3000 Rolls Crusher a larger and much more powerful rolls crusher with 2 x 350 mm rolls. A choice of two configurations gives you flexibility for continuous or batch use in laboratory and plant applications.

Lancaster Products Roll Crusher for Glass Manufacturing

Lancaster Products Roll Crushers are designed for long life. These crushers reduce in a single pass- material previously requiring primary and secondary crushing. 800.447.7351. About Us; Replaceable comb plates and cheek plates at the ends and sides of the housing prevent material from bypassing the rolls.

Qiming Casting-China’s wear-resistant casting industry leader

Qiming Casting produces wear parts in standard materials according to the actual needs of our customers. For example, high manganese crusher jaw plates, cone crusher liners, and side plates for stone crushers; High chrome steel rollers for vertical mills; Cr-mo alloy steel liners for ball mills. Redefining Wear Parts

Sampling Sizers/Roll Crushers McLanahan

Applications. Sampling Sizers/Roll Crushers retain the key features and benefits of the larger machine designs but are packaged into compact, cost-effective solutions specifically tailored to reliably and efficiently handle lower capacity applications. Double Roll Crushers are a widely used crusher type and offer advantages in relatively high

Roll Crusher Manufacturer Propel Industries

ROLL CRUSHER AVRC SERIES. New generation Roll Crusher has been designed using latest engineering tools for high reliability. It has premium features like high-efficiency gear drive and hydraulic gap management. Its features and the unique design help manufacture sand at lowest possible power consumption and liner wear cost.

Crusher Liners, Shredder Parts, Mill Liners Foundry- Hunan JY

2022年4月19日What We Offer. Hunan JY Casting manufactures crusher wear parts (cone crusher liners, crusher jaw plates, crusher blow bars), shredder wear parts (shredder hammer, grates, caps, anvils), mill liners (lifting plates, shell liners, end liners), and apron feeder pans for the most popular brands.

Cone Crusher Liners: How to Select and When to Change

2020年6月23日When to change Cone Crusher liners Liners that exceed their intended operating life will cause mechanical problems with the crusher. A liner that is pushed too long will flex and crack, and the flexing of a thin or cracked mantle will cause severe seat surface damage.

Single Roll Crushers by Pennsylvania Crusher Brand

Single Roll Crusher Models: Type K suited for the size reduction of materials having a compressive strength of 8,000 p.s.i. or less. Materials crushed typically include coal, petroleum coke, lignite and other friable substances. This model is also employed as a lump breaker for potash, chemicals, salts and similar minerals.

Used Crushers for Sale Mining | Surplus Record

Surplus Single Roll Pennsylvania Clinker Crusher Grinder CGA 33-30, Designed to reduce clinker material to 1 1/4" to 1 1/2", Frame is heavy-duty welded construction using 3/4"more View Details Contact Seller $17,500 Make Offer 4 Photos 33" United Conveyor Corp #33-Crusher, Carbon Steel Category: Crushers Seller: EcReCon Inc.