Quarry And Mining Flotation For Primary And Secondary Crushing

11.19.2 Crushed Stone Processing and Pulverized

Beneficiation processes use flotation to separate mineral impurities. Finely ground material is concentrated and flash dried. Fabric filters are used to Primary Crusher SCC 3-05

The effects of Drilling and Blasting Performance on

2015年8月24日The goal of the following project was to study the effect of production blasting on loading and hauling times, secondary breaking times and primary crushing

P&Q University Lesson 7- CrushingSecondary Breaking

2019年9月2日In the quarry, crushing is handled in four potential stages: primary, secondary, tertiary and quaternary. The reduction of aggregate is spread over these

Primary Crushing Mineral ProcessingMetallurgy

2016年2月26日The primary crushing setup is closely linked to the quarrying or mining operation, and it is only by careful adjustment of all equipment selections to the general

Standard Mineral Processing Plants -Standard Crushing Plants

Quarry Mining engineers design all our mineral processing plants to last for decades. Everything is of the highest quality, from wear-resistant spring wire screens to our locally

Secondary Crushing Equipment Mineral Processing

2016年2月28日The term “ secondary crushing ” has become well established and familiar through long usage; it applies to the crushing stage, either single or multiple,

secondary crushing MiningQuarry Plant

2013年3月12日The simplest form of secondary crushing stage involves a single crusher, taking its feed by gravity flow direct from the primary with no interposed

stationary secondary quarry plant MiningQuarry Plant

2013年9月10日kefid stationary granite quarry crushing plant consists of primary crushing, secondary crushing to fineness crushing. mobile and stationary crushing

What Is Primary, Secondary, and Tertiary Crushing?

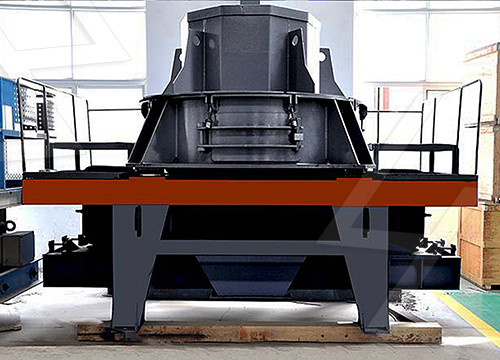

2021年1月10日Secondary crushing, as you can imagine, is the second stage of material processing following its initial reduction. At this stage, material will flow through perhaps

11.19.1 Sand And Gravel Processing US EPA

undergo primary crushing at the mine site before being transported to the processing plant. Figure 11.19.1-2 is a flow diagram for industrial sand and gravel processing. The mined rock is transported to the processing site and stockpiled. The material then is crushed. Depending on the degree of cementation, several stages of crushing may be

11.19.2 Crushed Stone Processing and Pulverized Mineral

Beneficiation processes use flotation to separate mineral impurities. Finely ground material is concentrated and flash dried. Fabric filters are used to Primary Crusher SCC 3-05-020-01 Secondary Cr usher SCC 3-05-020-02 Tertiary Crusher SCC 3-05-020-03 SCC 3 Fines Crus hers -05020 Sizing Screen SCC 3-05-020-021

Rock Crushers, Stone Crushers, Screening and Crushing

Rock Crushers. Optimize your operation and maximize your profitability with crushing and screening equipment. We offer mining jaw crushers, cone crushers, impact crushers, roll crushers and primary gyratory crushers for mining, quarrying and aggregate production. Our extensive expertise ranges from greenfield

P&Q University Lesson 7- CrushingSecondary Breaking

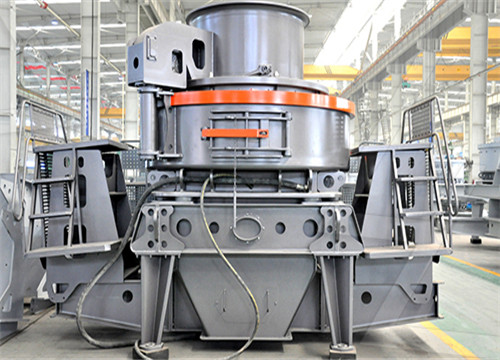

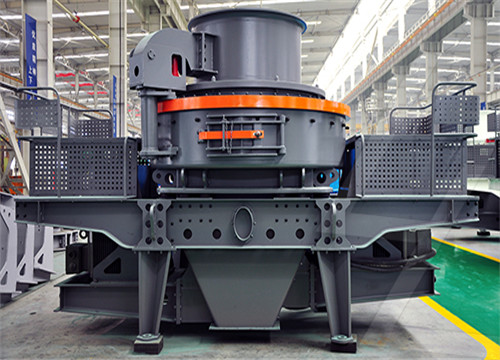

2019年9月2日In the quarry, crushing is handled in four potential stages: primary, secondary, tertiary and quaternary. The reduction of aggregate is spread over these stages to better control the product size and quality, while minimizing waste. The primary stage was once viewed merely as a means to further reduce stone following the blast or

Standard Mineral Processing Plants -Standard Crushing Plants

We also offer individual Mineral Processing Plants. We offer mpl crushers, impact, and cone. Choose from 3 or 4 final grain sizes, depending on your needs. The impact crusher plant produces volumes of 200 to 900 tonnes per hour, and the cone crusher provides from 150 to 400 tonnes per hour for final products of sand and aggregates.

Rock Crushing Process in Mining Mineral Processing

2015年7月18日Primary crushing is the first crushing stage, secondary crushing is the second, Tertiary crushing is the third, Quaternary crushing is a rare forth stage of rock crushing, Coarse crushing includes crushing operations discharging at sizes 4- to 6-in. or coarser; intermediate crushing comprises operations taking feeds 6- or 8-in. maximum

crushing milling flotation MiningQuarry Plant

2013年4月1日Crushing, grinding, froth flotation and gold recovery are carried out at the Fimiston plant The ore will be processed using a conventional crushing, milling,

primary grinding circuit MiningQuarry Plant

2013年7月18日B2Gold orders Metso Primary Crusher and Grinding Equipment. The primary grinding circuit will use a 24’ x 15.75’ sized SAG mill, followed by a 16.5’ × 28.5’ secondary ball mill. Both mills will have a 4 MW .

What Type of Crusher Is Best for Primary Crushing?

2021年3月25日Gyratory Crushers are an excellent choice for a primary crusher, as they can handle very hard and abrasive material. They are ideal for dry to slightly wet material but not sticky material. Gyratories are compression crushers primarily used for heavy mining and quarried materials in extremely high tonnage applications.

Types of Rock Crushers Quarry Crushing Equipment Kemper

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2. Secondary

sbmchina/sbm crushing copper stage.md at main github

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Crushing and sizing technology for all stages

Crushing and sizing. Robust. Reliable. Crushing and sizing equipment that’s up to the task. The demands on your crushing and sizing equipment are extreme. Crunching up rock without breaking teeth. Reducing sticky and soft materials without clogging. Your process depends on the ability of these machines to do their jobs so we make it our

Stone-Crusher Quarry Mining LLC Mining Plant Experts in UAE

2020年7月26日These stone crushers are suitable for continuous use in a quarry or mining operation. They can integrate with an entirely automated crushing process line. Soft to very hard rock. Sand, gravel, or recycling. Reduction ratios from 3:1 to 8:1. Natural stone or mining operations. Primary, secondary, and tertiary crushing.

How To Select Your Primary Crusher JXSC Mining

2019年11月19日2019-11-19 by JXSC Mining. How you select the best primary crusher from all of the available primary crushers is required a great deal of design based on the mining plan and operation input. Usually, capacity, feed size, product size, rock compressive strength, abrasion index and mobility of crusher are considering as criteria,

11.19.1 Sand And Gravel Processing US EPA

undergo primary crushing at the mine site before being transported to the processing plant. Figure 11.19.1-2 is a flow diagram for industrial sand and gravel processing. The mined rock is transported to the processing site and stockpiled. The material then is crushed. Depending on the degree of cementation, several stages of crushing may be

Rock Crushers, Stone Crushers, Screening and Crushing

Rock Crushers. Optimize your operation and maximize your profitability with crushing and screening equipment. We offer mining jaw crushers, cone crushers, impact crushers, roll crushers and primary gyratory crushers for mining, quarrying and aggregate production. Our extensive expertise ranges from greenfield

Types of Rock Crushers Quarry Crushing Equipment Kemper

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2. Secondary

P&Q University Lesson 7- CrushingSecondary Breaking

2019年9月2日In the quarry, crushing is handled in four potential stages: primary, secondary, tertiary and quaternary. The reduction of aggregate is spread over these stages to better control the product size and quality, while minimizing waste. The primary stage was once viewed merely as a means to further reduce stone following the blast or

Standard Mineral Processing Plants -Standard Crushing Plants

Quarry Mining engineers design all our mineral processing plants to last for decades. Everything is of the highest quality, from wear-resistant spring wire screens to our locally produced steel framework. Our plants require less maintenance time and can increase productivity by 25% over other plants.

Crushing and Screening Agg-Net

The quarry’s annual production and operating hours also need to be determined. The entire system should be checked by an experienced crushing and screening expert with a computer flow simulation program to optimize the output and efficiency. The primary crusher is usually oversized in terms of capacity and operated at a lower efficiency

crushing milling flotation MiningQuarry Plant

2013年4月1日crushing milling copper leaching Quarrying Crusher Plant crushing milling copper leaching Copper ore Conventional Milling/Flotation,Copper process plant includes oxide circuit crushing, milling, flotation, crushing and milling plant mobile crushing milling plant Grinding Plant. crushing, grinding, flotation.

sbmchina/sbm crushing copper stage.md at main github

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

secondary crushing MiningQuarry Plant

2013年3月12日The simplest form of secondary crushing stage involves a single crusher, taking its feed by gravity flow direct from the primary with no interposed scalping separation. crushing primary secondary tertiary Mining equipmentmine Mining primary impact crusher for sale,primary secondary tertiary How to Choose Primary

What Type of Crusher Is Best for Primary Crushing?

2021年3月25日These types of compression crushers are best suited for heavy mining, quarried materials, sand and gravel, and recycling applications. They provide a reduction ratio of 3:1 to 6:1. Jaw Crushers feature a moving piece of steel (called the pitman) and a stationary piece of steel that form a V-shaped chamber.

Stone-Crusher Quarry Mining LLC Mining Plant Experts in UAE

2020年7月26日Primary Crushing Technology Kleeman crushers can withstand the daily demands of quarry operations. Jaw crushers are the best choice for primary crushing. They can handle a broad range of materials from soft to very hard rock, breaking them along natural cracks resulting in stones with flat ends.

crushing milling and flotation process images of small size quarry

Contribute to jidafang2022/en development by creating an account on GitHub.

Electric Site Research Project Volvo Construction Equipment

Drawing on the electromobility and automation expertise of the Volvo Group, the research project, dubbed Electric Site, aims to electrify each transport stage in a quarry from excavation to primary crushing, and transport to secondary crushing although a negligible amount of diesel power will still be used.

Mobile crushers and screens — SRP

We offer a wide range of mobile crushers and screens, both tracked and wheeled, to help you process rock in the toughest conditions. This selection includes jaw crushers, impactors, cone crushers, screens and scalpers for quarrying, construction and rock excavation projects. Email us Request a quote Powerful, agile and fully mobile crushers